Maintenance Engineered Hacksaw Blade, Bimetal Construction, 12" Length, 26-32TPI

(Pack of

10)

SKU:51226M01 Item#: 51226M01

Tackle tough jobs with the versatility and strength of Hardflex® Hacksaw Blades. Made in the USA, these variable pitch blades cut faster, stay cooler, and deliver smoother finishes, especially on hard-to-cut materials like stainless steel. Their bi-metal construction resists shattering while delivering exceptional performance under tension. The wavy tooth set ensures better chip removal and reduced binding in thin materials, making them ideal for a wide range of cutting applications.

• Variable pitch design for faster cutting and better chip formation

• Reduces heat buildup—ideal for stainless steel and work-hardened materials

• Each blade covers a wider range of materials and thicknesses

• Bi-metal construction with electronically welded matrix alloy edge

• Resists fatigue, shock, and heavy pressures

• Can be tensioned to 30,000 PSI in a Hardflex® frame

• Wavy set teeth enhance contact area and accuracy, reduce tooth stripping

• Best for thin-walled or variable thickness workpieces

• Made in the USA

CAUTION: Any cutting tool may break or shatter under improper use. Government regulations require use of safety glasses and other appropriate safety equipment at all times in the vicinity of use.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov

Catalog page#: 11-81

Frequently Bought Together

Jobber Length Drill Bit HSS 3/32"

Couldn't load pickup availability

Twist-On Surface Conditioning Disc 2" Blue

Couldn't load pickup availability

Scotch-Brite Roloc Bristle Disc 2"

Couldn't load pickup availability

Standard Bimetal Hacksaw Blade 12"

Couldn't load pickup availability

Standard Bimetal Hacksaw Blade 12"

Couldn't load pickup availability

14" Power Hacksaw Blade, 1" wide, 10 TPI

Couldn't load pickup availability

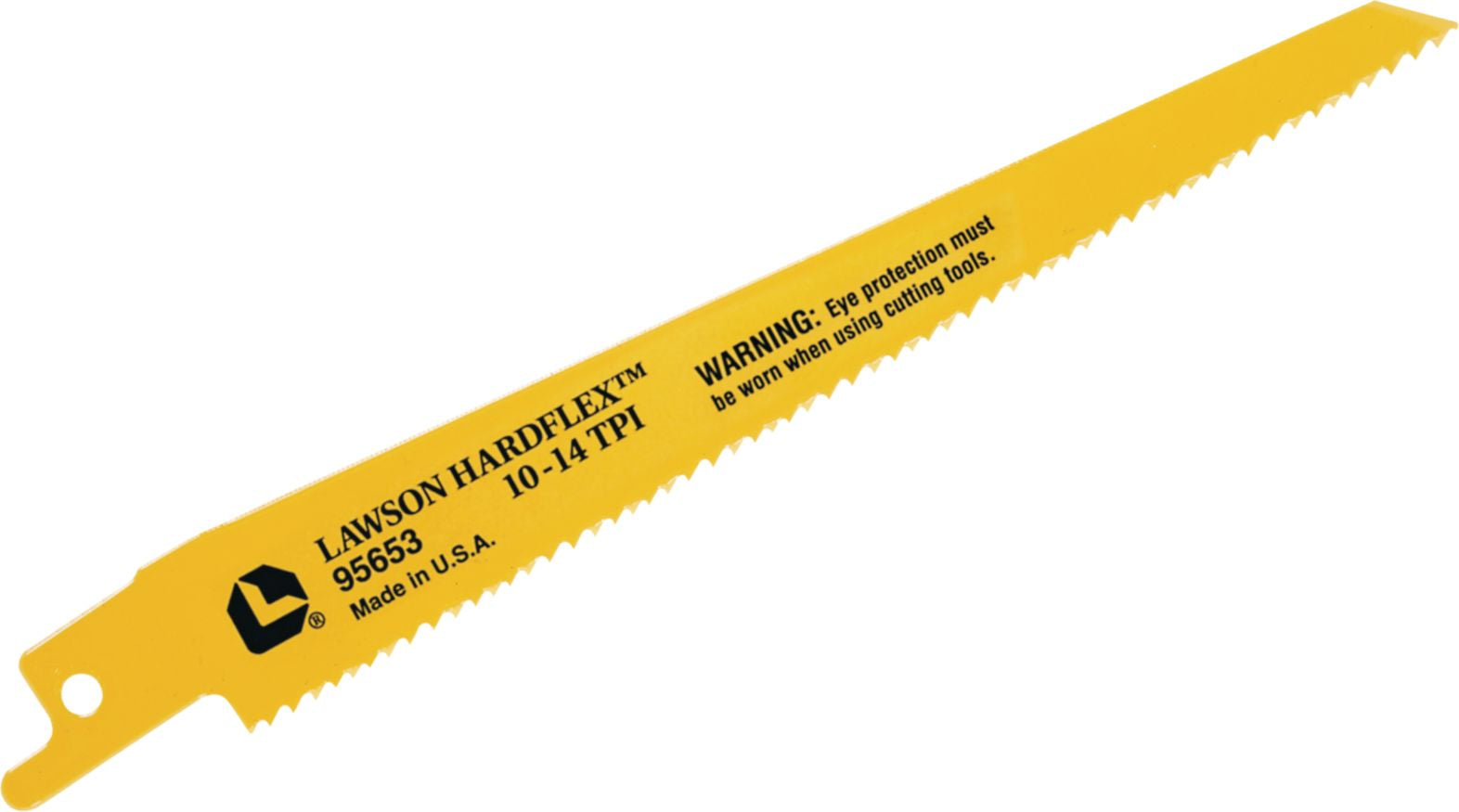

Tapered Reciprocating Saw Blade 12"

Couldn't load pickup availability

General Purpose Reciprocating Saw Blade 4"

Couldn't load pickup availability

Bandsaw Blade 10/14 TPI 107"

Couldn't load pickup availability

Flat Washer Grade 12 Thru-Hardened Steel M12

Couldn't load pickup availability

18" Locking Smooth Operator Clamp

Couldn't load pickup availability

Hex Nut Grade 8 Alloy Steel 5/16-18

Couldn't load pickup availability

Screwdriver Anti Slip Phillips No 2 X 4In

Couldn't load pickup availability

Twist-On Surface Conditioning Disc 3" Maroon

Couldn't load pickup availability

Jobber Length Drill Bit HSS 25/64"

Couldn't load pickup availability

Product Description

Tackle tough jobs with the versatility and strength of Hardflex® Hacksaw Blades. Made in the USA, these variable pitch blades cut faster, stay cooler, and deliver smoother finishes, especially on hard-to-cut materials like stainless steel. Their bi-metal construction resists shattering while delivering exceptional performance under tension. The wavy tooth set ensures better chip removal and reduced binding in thin materials, making them ideal for a wide range of cutting applications.• Variable pitch design for faster cutting and better chip formation

• Reduces heat buildup—ideal for stainless steel and work-hardened materials

• Each blade covers a wider range of materials and thicknesses

• Bi-metal construction with electronically welded matrix alloy edge

• Resists fatigue, shock, and heavy pressures

• Can be tensioned to 30,000 PSI in a Hardflex® frame

• Wavy set teeth enhance contact area and accuracy, reduce tooth stripping

• Best for thin-walled or variable thickness workpieces

• Made in the USA

CAUTION: Any cutting tool may break or shatter under improper use. Government regulations require use of safety glasses and other appropriate safety equipment at all times in the vicinity of use.

Technical Specifications

| Item#: | 51226M01 |

|---|---|

| Type | Standard |

| Length | 12 " |

| Teeth per Inch | 26-32 |

| Material Thickness | 1/16" and Thinner |

| UNSPSC #: | 27111559 |

| TAA Compliant: | Yes |

| Weight: | 0.45 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov