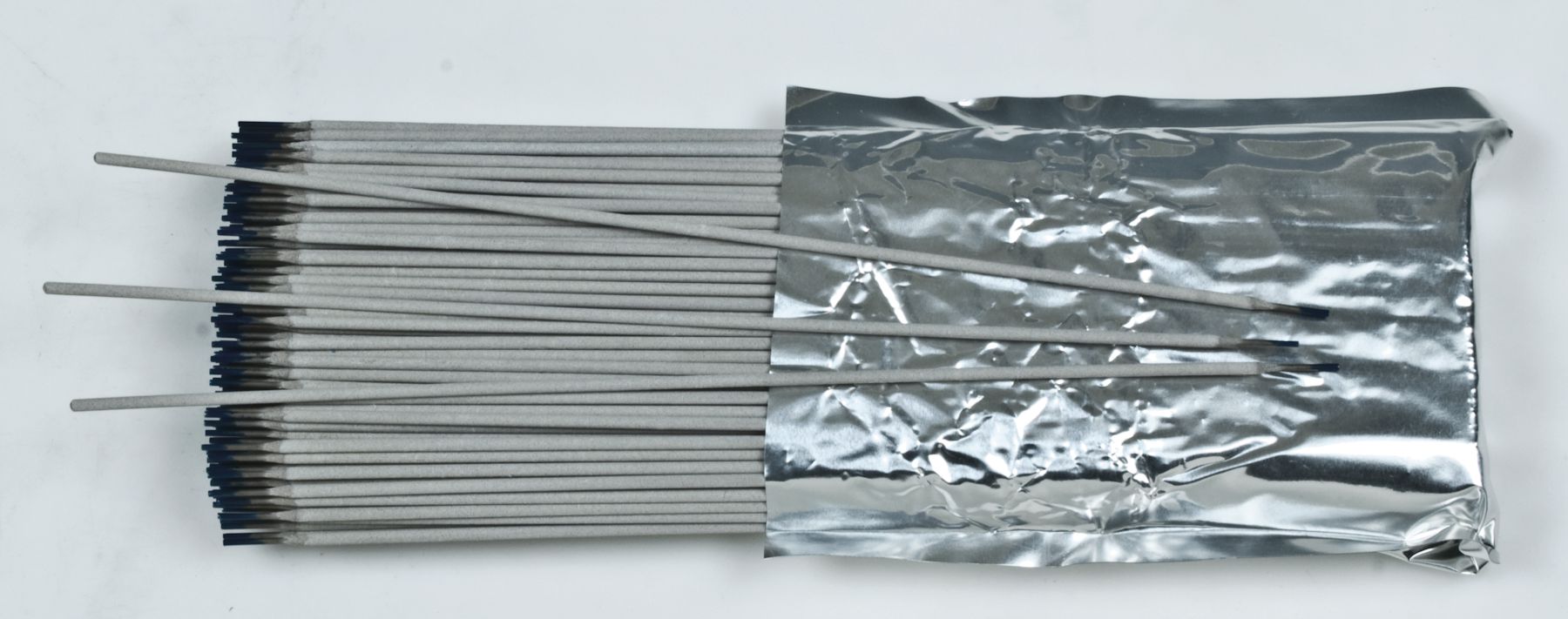

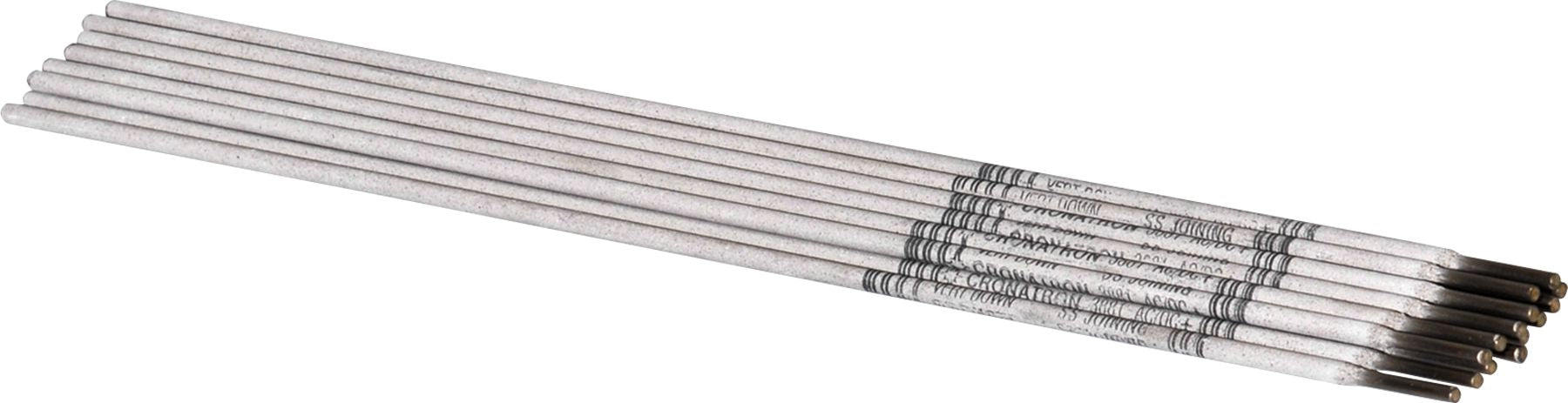

3000 Nickel Stick Rod Electrode, Flux Coated, 50 to 70 Amps, 33% Elongation, DCRP Polarity, Extremely Corrosion-Resistant, 3/32"

(Pack of

5)

SKU:CW1992 Item#: CW1992

Compatible with Inconel, other nickel-based alloys, Monel® and dissimilar alloys.

Superior Advantages

• Extremely corrosion-resistant

• High temperature usage – up to 2,000°F (1,093°C)

• Low temperature usage – down to –320°F (–196°C)

• Maximum versatility

• Dissimilar metals joining

Withstands operating temperatures from –320°F to +2,000°F (–196°C to +1,093°C).

Tensile Strength: 100,000 PSIElongation: 33%Polarity: DC Reverse

Typical Applications

• Furnaces and boilers

• Heat treat baskets

• Power plants

• Chemical processing

Usage ProcedureUse DC reverse polarity with normal maintenance welding procedures. Surface should be as clean as possible. Hold a short arc and tilt electrode 10° in the direction of travel. Remove slag between passes. Preheating the weld metal is not necessary unless the base metal and/or thickness require it. Do not weave more than twice the diameter of the core wire.

Frequently Bought Together

SAE J995C Locknut with Nylon Insert Grade 8 1/4-20

Couldn't load pickup availability

Cross-Over Socket Extension Set, 3/8" Drive, 3 Piece

Couldn't load pickup availability

IFI 100/107 Top Locknut Grade C 5/8-11

Couldn't load pickup availability

ER308L Stainless Steel MIG Welding Wire 0.045"

Couldn't load pickup availability

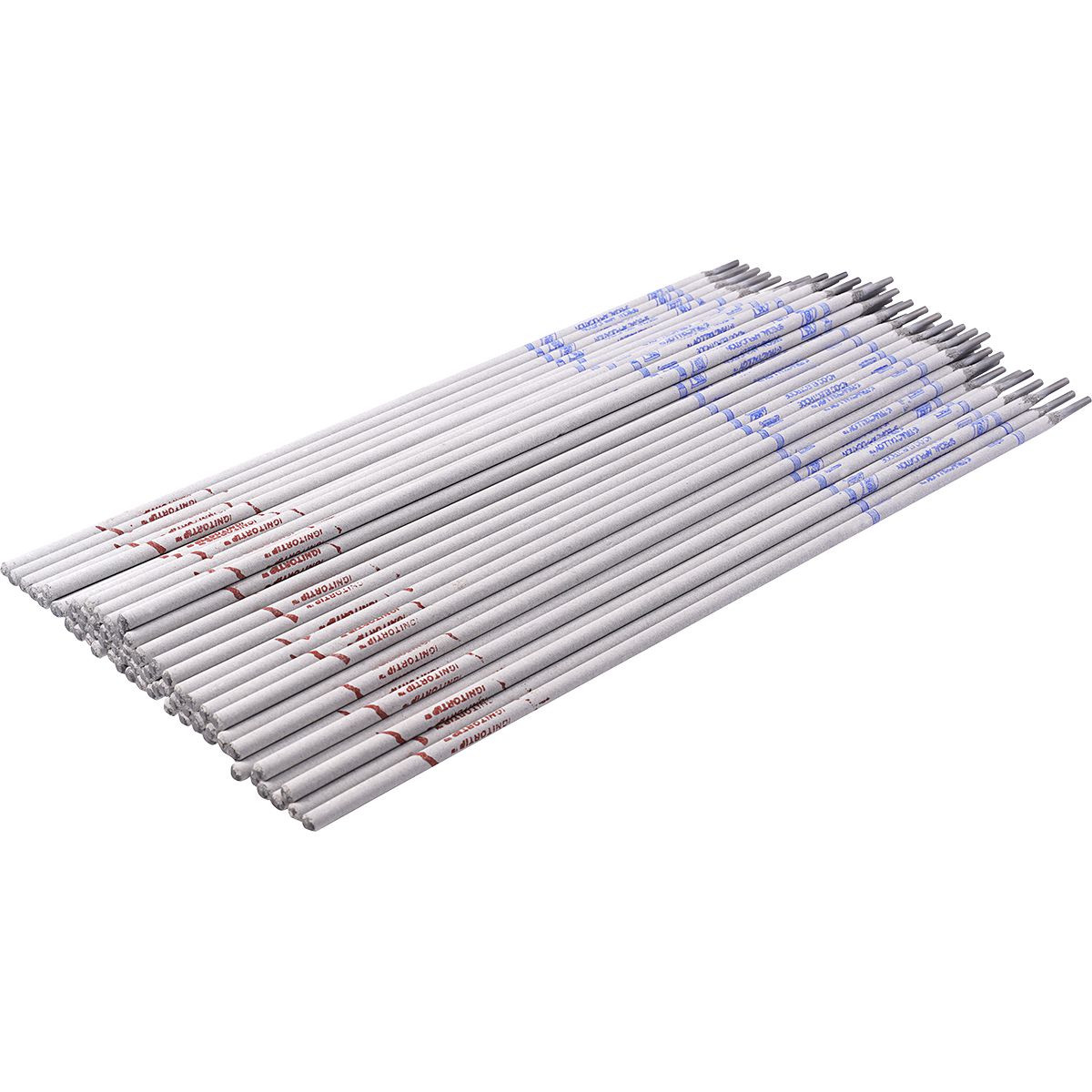

3880 Stainless Steel Stick Rod Electrode 1/16"

Couldn't load pickup availability

3881 Stainless Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

45 Silver Bare Brazing Rod 1/8"

Couldn't load pickup availability

Rosin Core Solder 1/16"

Couldn't load pickup availability

Rosin Core Solder 1/16"

Couldn't load pickup availability

X-Tractalloy Extracting Welding Electrode Non-Conductive Flux 3/32

Couldn't load pickup availability

331 Mild and Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

345 Tool Steel TIG Wire 3/32"

Couldn't load pickup availability

Product Description

Compatible with Inconel, other nickel-based alloys, Monel® and dissimilar alloys.Superior Advantages

• Extremely corrosion-resistant

• High temperature usage – up to 2,000°F (1,093°C)

• Low temperature usage – down to –320°F (–196°C)

• Maximum versatility

• Dissimilar metals joining

Withstands operating temperatures from –320°F to +2,000°F (–196°C to +1,093°C).

Tensile Strength: 100,000 PSIElongation: 33%Polarity: DC Reverse

Typical Applications

• Furnaces and boilers

• Heat treat baskets

• Power plants

• Chemical processing

Usage ProcedureUse DC reverse polarity with normal maintenance welding procedures. Surface should be as clean as possible. Hold a short arc and tilt electrode 10° in the direction of travel. Remove slag between passes. Preheating the weld metal is not necessary unless the base metal and/or thickness require it. Do not weave more than twice the diameter of the core wire.

Technical Specifications

| Item#: | CW1992 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 3/32 " |

| Tensile Strength | 100,000 PSI |

| Elongation | 33 % |

| Base Metal | Nickel |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.0 lb |

Product Restrictions