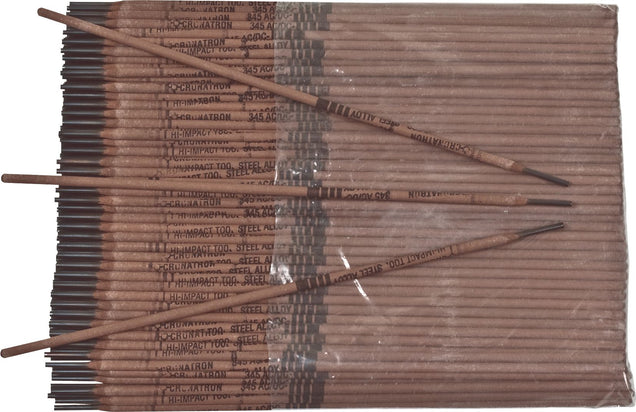

345 Tool Steel TIG Wire, Solid, 54 to 58 HRC Hardness, 100% Ar Shielding Gas, DCSP Polarity, 36" Length, 3/32"

(Pack of

2)

SKU:CW1889 Item#: CW1889

A broad selection of premium alloys to use for nearly any tool steel application and repair.

Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 54-58

Polarity: DC Straight

Gas: 100% Ar

Universal and “H” Series, Chromium Hot Work Tool SteelThe principal elements in this alloy are chromium, tungsten, moly and vanadium. This chemistry provides an extremely tough deposit with deep air-hardening capabilities up to 12". Types: H11, 12, 13, S1, S7, 01, 06.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Frequently Bought Together

Butt Connector 16 to 14 AWG Clear

Couldn't load pickup availability

Butt Connector 22 to 18 AWG Clear

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 1/4"

Couldn't load pickup availability

346 Tool Steel TIG Wire 1/16"

Couldn't load pickup availability

349 Tool Steel TIG Wire 3/32"

Couldn't load pickup availability

349 Tool Steel TIG Wire 0.035"

Couldn't load pickup availability

176 Extreme Abrasion With Impact 1/4X18IN

Couldn't load pickup availability

Rosin Core Solder 0.032"

Couldn't load pickup availability

333 Dissimilar Steel TIG Wire 1/16"

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

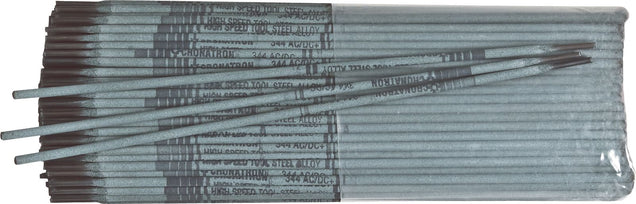

344 Tool Steel TIG Wire 1/16"

Couldn't load pickup availability

Product Description

A broad selection of premium alloys to use for nearly any tool steel application and repair.Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 54-58

Polarity: DC Straight

Gas: 100% Ar

Universal and “H” Series, Chromium Hot Work Tool SteelThe principal elements in this alloy are chromium, tungsten, moly and vanadium. This chemistry provides an extremely tough deposit with deep air-hardening capabilities up to 12". Types: H11, 12, 13, S1, S7, 01, 06.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Technical Specifications

| Item#: | CW1889 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | 3/32 " |

| Length | 36 " |

| Base Metal | Tool Steel |

| Hardness | 54-58 HRC |

| Shielding Gas | 100% Ar |

| Polarity | DCSP |

| Quantity Per Package | 2.0000 |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 0.5 lb |

Product Restrictions