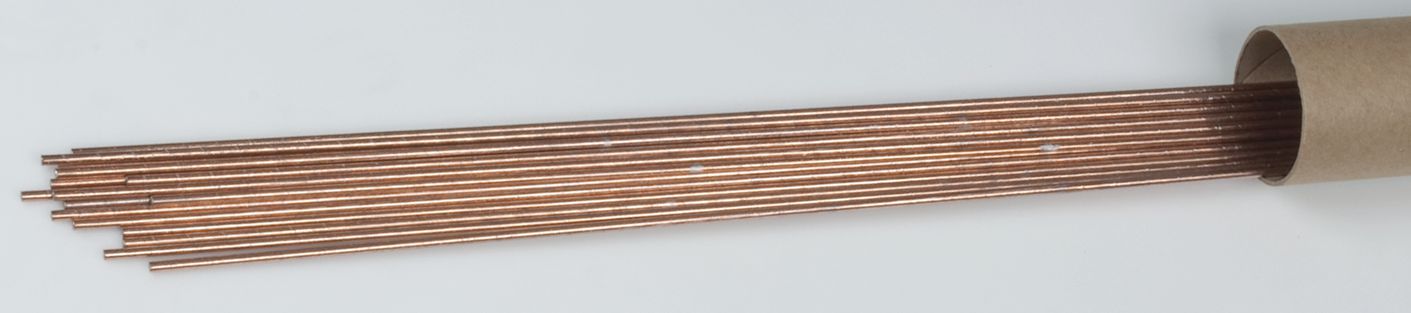

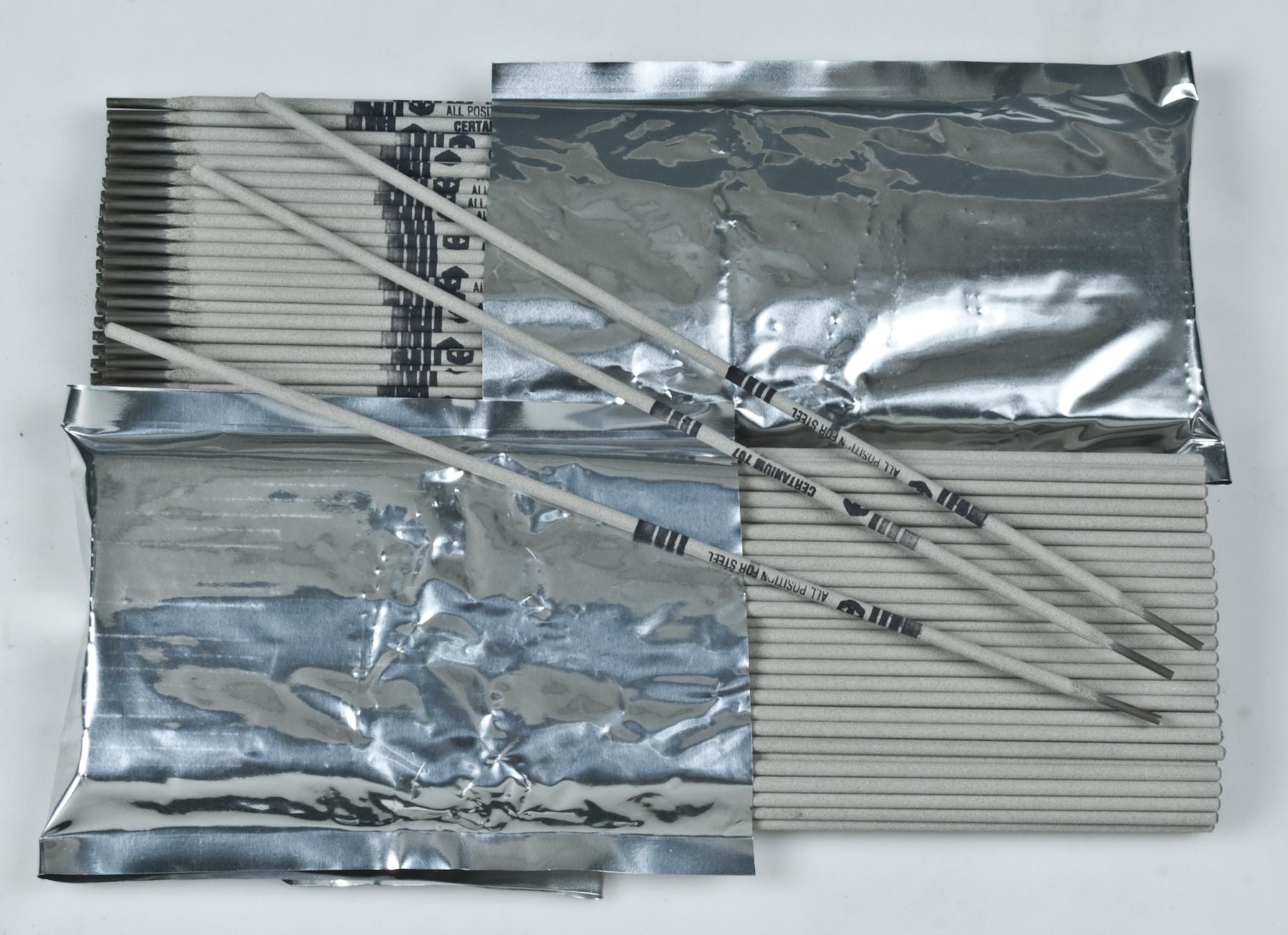

349 Tool Steel TIG Wire, Solid, 33 to 36 HRC Hardness, 100% Ar Shielding Gas, 26% Elongation, 36" Length, 3/32"

(Pack of

2)

SKU:CW1980 Item#: CW1980

Specially formulated for welding P-mold steels and most chrome-moly alloy steels.

Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Tensile Strength: 89,700 PSIYield Strength: 73,400 PSIElongation: 26%Hardness: Rc 33-36Polarity: DC StraightGas: 100% Ar

Typical Applications

• Die-casting dies

• Injection molds

• Compression molding of plastics and chrome-moly steels like AISI 4130, 4140, 8620 and 8640

Usage ProcedureMaintain a short arc with minimal weave. Preheat as prescribed by base metal.

Frequently Bought Together

USS Flat Washer Thru-Hardened Steel 5/16"

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 3/8"

Couldn't load pickup availability

Stepdown Butt Connector 16 to 14/12 to 10 AWG

Couldn't load pickup availability

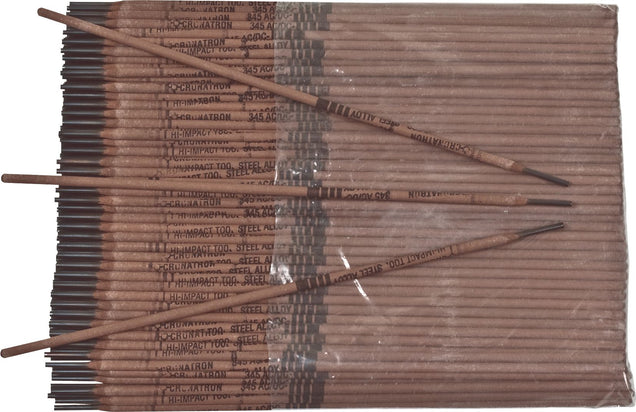

349 Tool Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

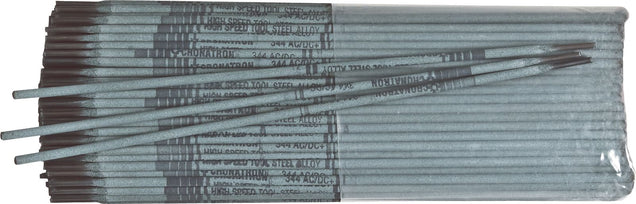

344 Tool Steel TIG Wire 0.035"

Couldn't load pickup availability

349 Tool Steel TIG Wire 1/8"

Couldn't load pickup availability

510 Aluminum TIG Wire 3/32"

Couldn't load pickup availability

Oxy Acetylene Fuel Gas Three Flint Striker

Couldn't load pickup availability

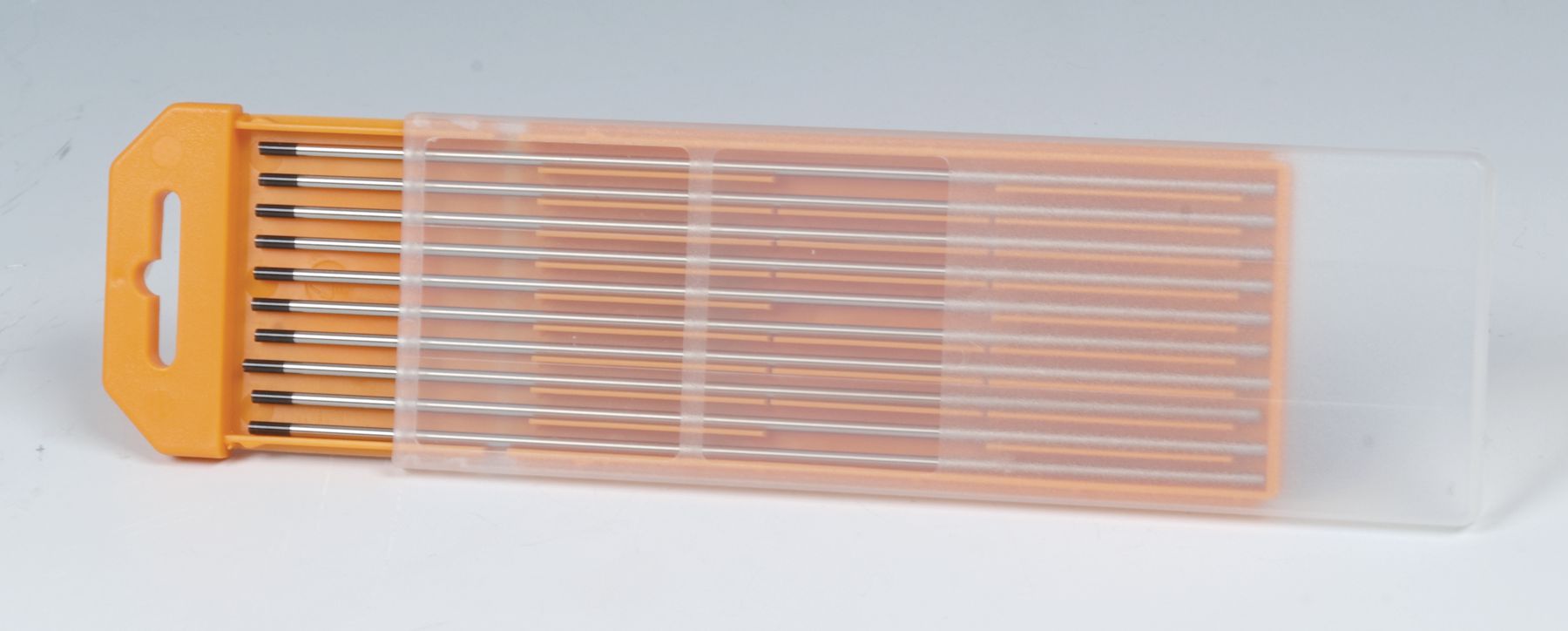

TIG Welding Electrode 3/32"

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 5/32"

Couldn't load pickup availability

556 Aluminum TIG Wire 1/16"

Couldn't load pickup availability

707 Dissimilar Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

Product Description

Specially formulated for welding P-mold steels and most chrome-moly alloy steels.Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Tensile Strength: 89,700 PSIYield Strength: 73,400 PSIElongation: 26%Hardness: Rc 33-36Polarity: DC StraightGas: 100% Ar

Typical Applications

• Die-casting dies

• Injection molds

• Compression molding of plastics and chrome-moly steels like AISI 4130, 4140, 8620 and 8640

Usage ProcedureMaintain a short arc with minimal weave. Preheat as prescribed by base metal.

Technical Specifications

| Item#: | CW1980 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | 3/32 " |

| Length | 36 " |

| Tensile Strength | 89,700 PSI |

| Yield Strength | 73,400 PSI |

| Elongation | 26 % |

| Base Metal | Tool Steel |

| Hardness | 33-36 HRC |

| Shielding Gas | 100% Ar |

| Polarity | DCSP |

| Quantity Per Package | 2.0000 |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 2.5 lb |

Product Restrictions