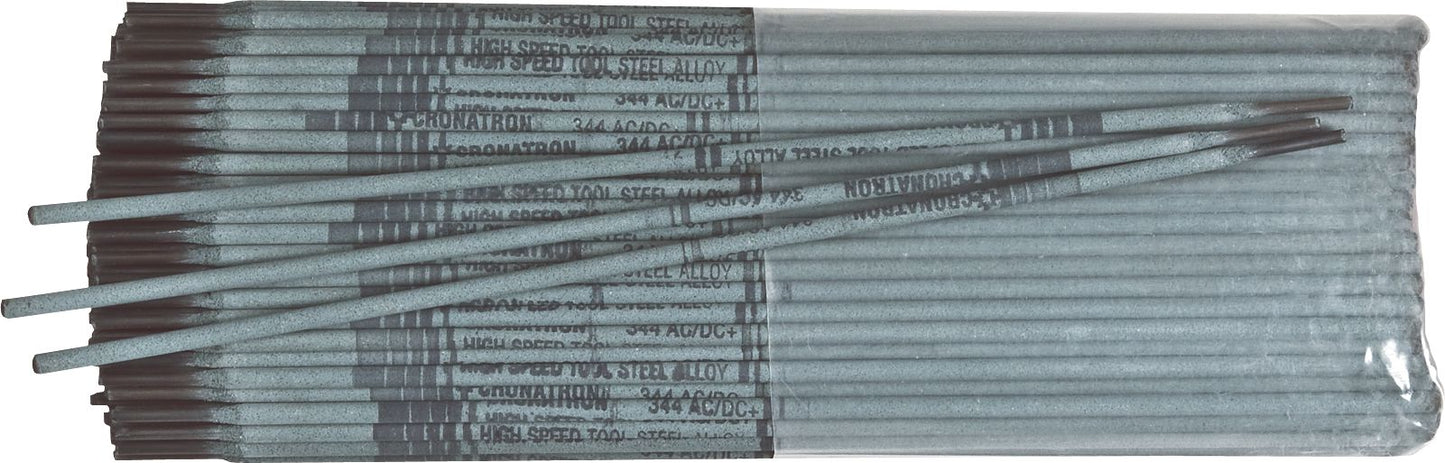

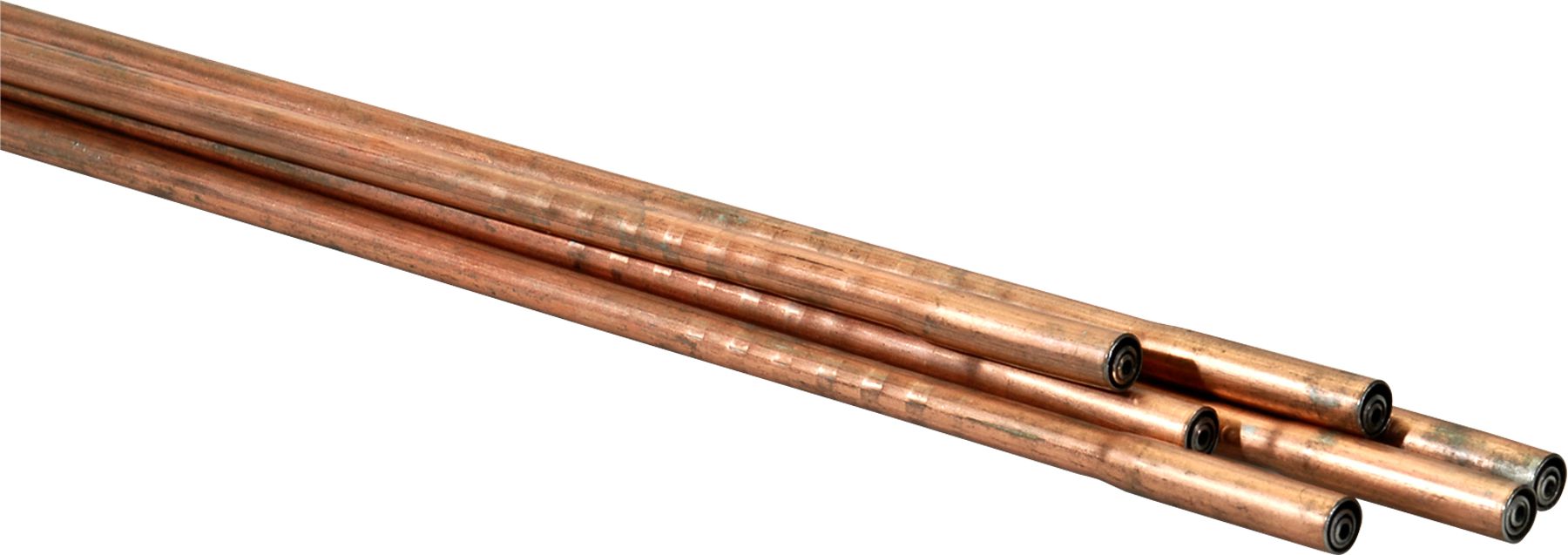

344 Tool Steel Stick Rod Electrode, Flux Coated, 59 to 63 HRC Hardness, 50 to 90 Amps, DCRP/AC Polarity, Crack-Resistant, 3/32"

(Pack of

5)

SKU:CW1068 Item#: CW1068

A broad selection of premium alloys to use for nearly any tool steel application and repair.

Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 59-63Polarity: AC or DC Reverse

“D” and “M” SeriesThis alloy was formulated for welding the “D” and “M” Series, due to its very high percentage of carbon and alloy additions of chromium, molybdenum and vanadium. The deposits are air-hardenedable and require high preheat temperatures for welding types D-2, M-2.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Usage ProcedureWhen used on hardened tool steels, preheat the steel to 150°F (65°C) below the draw temperature of the steel. Base metal should be cleaned to remove oil and other contaminants. Sharp edges should be removed where possible and chipped, spalled, or fatigued metal should be removed by grinding or other mechanical means. Deposits should be peened after each pass immediately after deposition to relieve stresses. Use care in removing slag thoroughly between multiple passes.

Frequently Bought Together

Hex Nut Grade 8 Alloy Steel 1/4-20

Couldn't load pickup availability

Hex Nut Grade 8 Alloy Steel 3/8-16

Couldn't load pickup availability

Superbutt Connector 22 to 18 AWG Red

Couldn't load pickup availability

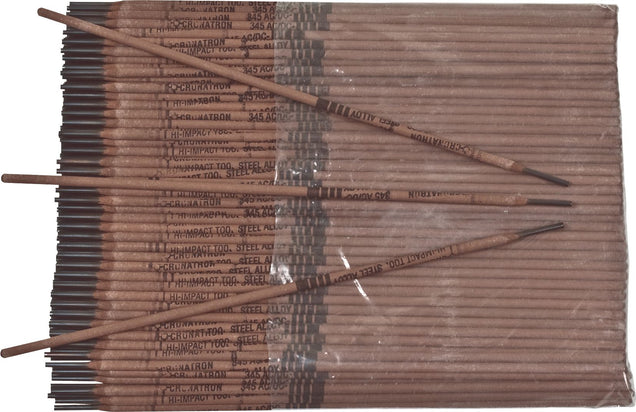

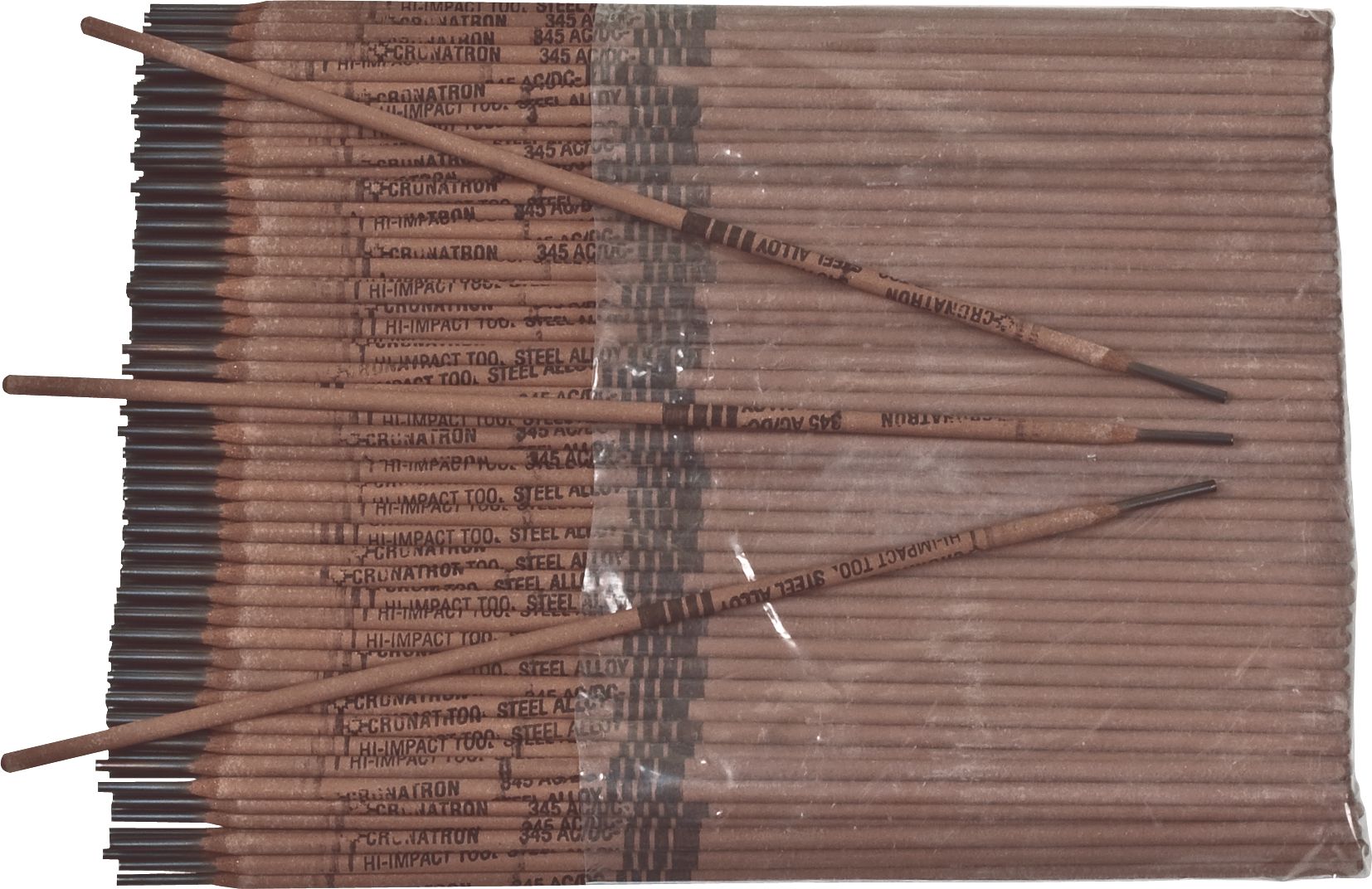

345 Tool Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

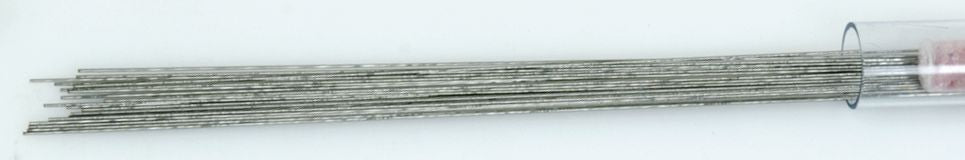

349 Tool Steel TIG Wire 0.02"

Couldn't load pickup availability

349 Tool Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

Oxy-Therm Cutting Rod 3/8 x 24"

Couldn't load pickup availability

40 High Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

Rosin Core Solder 0.032"

Couldn't load pickup availability

106 Mild Steel All Purpose Electrode

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 5/32"

Couldn't load pickup availability

556 Aluminum TIG Wire 1/16"

Couldn't load pickup availability

Product Description

A broad selection of premium alloys to use for nearly any tool steel application and repair.Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 59-63Polarity: AC or DC Reverse

“D” and “M” SeriesThis alloy was formulated for welding the “D” and “M” Series, due to its very high percentage of carbon and alloy additions of chromium, molybdenum and vanadium. The deposits are air-hardenedable and require high preheat temperatures for welding types D-2, M-2.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Usage ProcedureWhen used on hardened tool steels, preheat the steel to 150°F (65°C) below the draw temperature of the steel. Base metal should be cleaned to remove oil and other contaminants. Sharp edges should be removed where possible and chipped, spalled, or fatigued metal should be removed by grinding or other mechanical means. Deposits should be peened after each pass immediately after deposition to relieve stresses. Use care in removing slag thoroughly between multiple passes.

Technical Specifications

| Item#: | CW1068 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 3/32 " |

| Base Metal | Tool Steel |

| Hardness | 59-63 HRC |

| Polarity | DCRP/AC |

| Quantity Per Package | 5.0000 |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.0 lb |

Product Restrictions