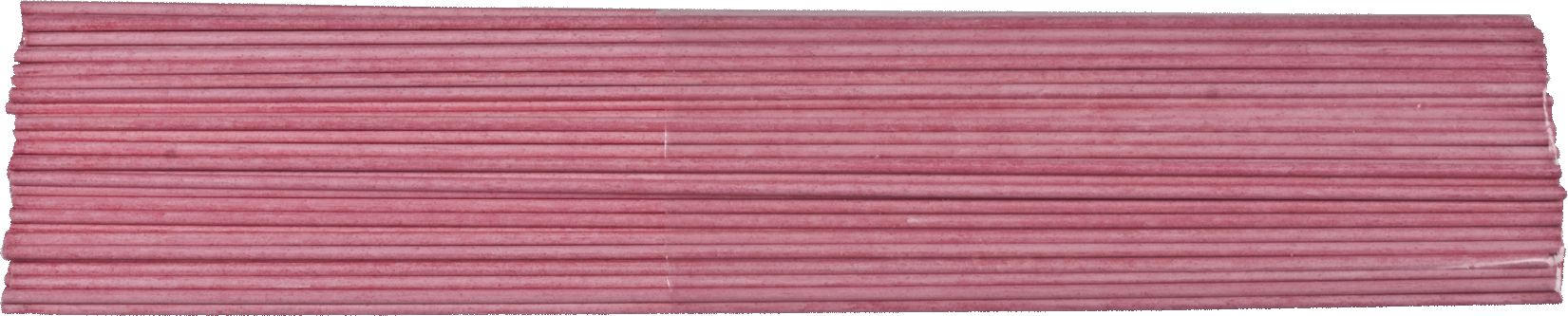

40 High Silver Flux Coated Brazing Rod, Orange, 18" Length, 1/16"

(Pack of

6)

SKU:CW1025 Item#: CW1025

Providing maximum capillary action and the lowest melting temperatures, these high silver products waste less brazing alloy. They have the ability to join many different metals – tool steel, stainless steel, alloy steel, copper and brass alloys and many others.

Superior Advantages

• Thin flow provides excellent capillary action

• Excellent electrical conductivity

• Low melt temperatures

Cadmium-free, use for food, beverage and kitchen equipment

Flux Coating Color: OrangeTensile Strength: 85,000 PSIMelting Temperature: 1,140°F (616°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical components

• Carbide tipping

• Copper coils and tubing

• Food, beverage and kitchen equipment (cadmium-free products)

Usage ProcedureMaterials should be smooth and free of burrs or uneven edges. A carburizing oxyacetylene flame should be used, heating a broad surface along the joint line. Keep the flame cone one inch ahead of the alloy rod and a continuous fillet will form. Clean flux residue off with water.

Couldn't load pickup availability

Catalog page#: 13-27

Frequently Bought Together

30 Copper and Steel Flux Coated Brazing Rod 3/32"

Couldn't load pickup availability

202Xl Red Flux Coated Brazing Alloy 3/16

Couldn't load pickup availability

30 Copper and Steel Flux Coated Brazing Rod 1/8"

Couldn't load pickup availability

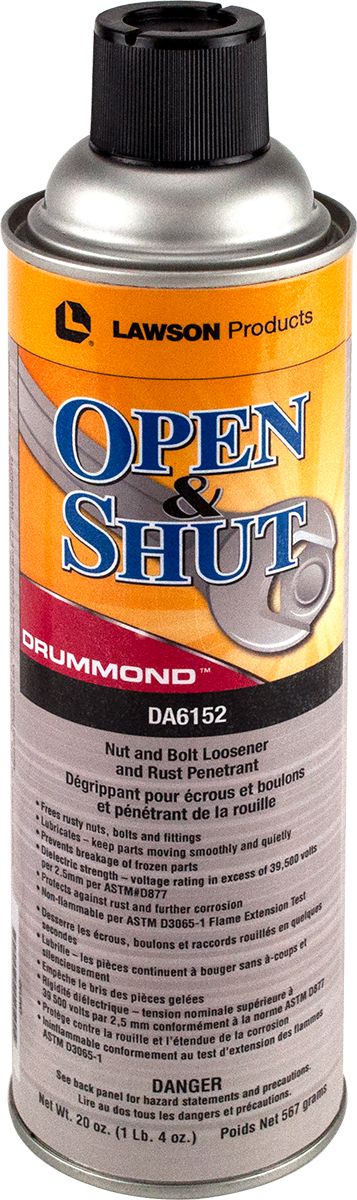

Lawson Open & Shut Nut & Bolt Loosener, Rust Penetrant, SKU DA6152, 20 oz Aerosol Can

Couldn't load pickup availability

SAE J995C Locknut with Nylon Insert Grade 8 1/4-20

Couldn't load pickup availability

Cross-Over Socket Extension Set, 3/8" Drive, 3 Piece

Couldn't load pickup availability

54 Medium Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

52 Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

40 High Silver Bare Brazing Rod 1/16"

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

45 Silver Bare Brazing Rod 1/8"

Couldn't load pickup availability

Rosin Core Solder 1/16"

Couldn't load pickup availability

Product Description

Providing maximum capillary action and the lowest melting temperatures, these high silver products waste less brazing alloy. They have the ability to join many different metals – tool steel, stainless steel, alloy steel, copper and brass alloys and many others.Superior Advantages

• Thin flow provides excellent capillary action

• Excellent electrical conductivity

• Low melt temperatures

Cadmium-free, use for food, beverage and kitchen equipment

Flux Coating Color: OrangeTensile Strength: 85,000 PSIMelting Temperature: 1,140°F (616°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical components

• Carbide tipping

• Copper coils and tubing

• Food, beverage and kitchen equipment (cadmium-free products)

Usage ProcedureMaterials should be smooth and free of burrs or uneven edges. A carburizing oxyacetylene flame should be used, heating a broad surface along the joint line. Keep the flame cone one inch ahead of the alloy rod and a continuous fillet will form. Clean flux residue off with water.

Technical Specifications

| Item#: | CW1025 |

|---|---|

| Welding Process | Brazing |

| Type | Flux Coating |

| Diameter | 1/16 " |

| Length | 18 " |

| Tensile Strength | 85,000 PSI |

| Melting Temperature | 1140 °F |

| Color | Orange |

| Base Metal | Silver |

| Silver Content | High |

| Recommended Flux | F40 |

| Description | High Silver |

| UNSPSC #: | 23271804 |

| TAA Compliant: | Yes |

| Weight: | 0.54 lb |