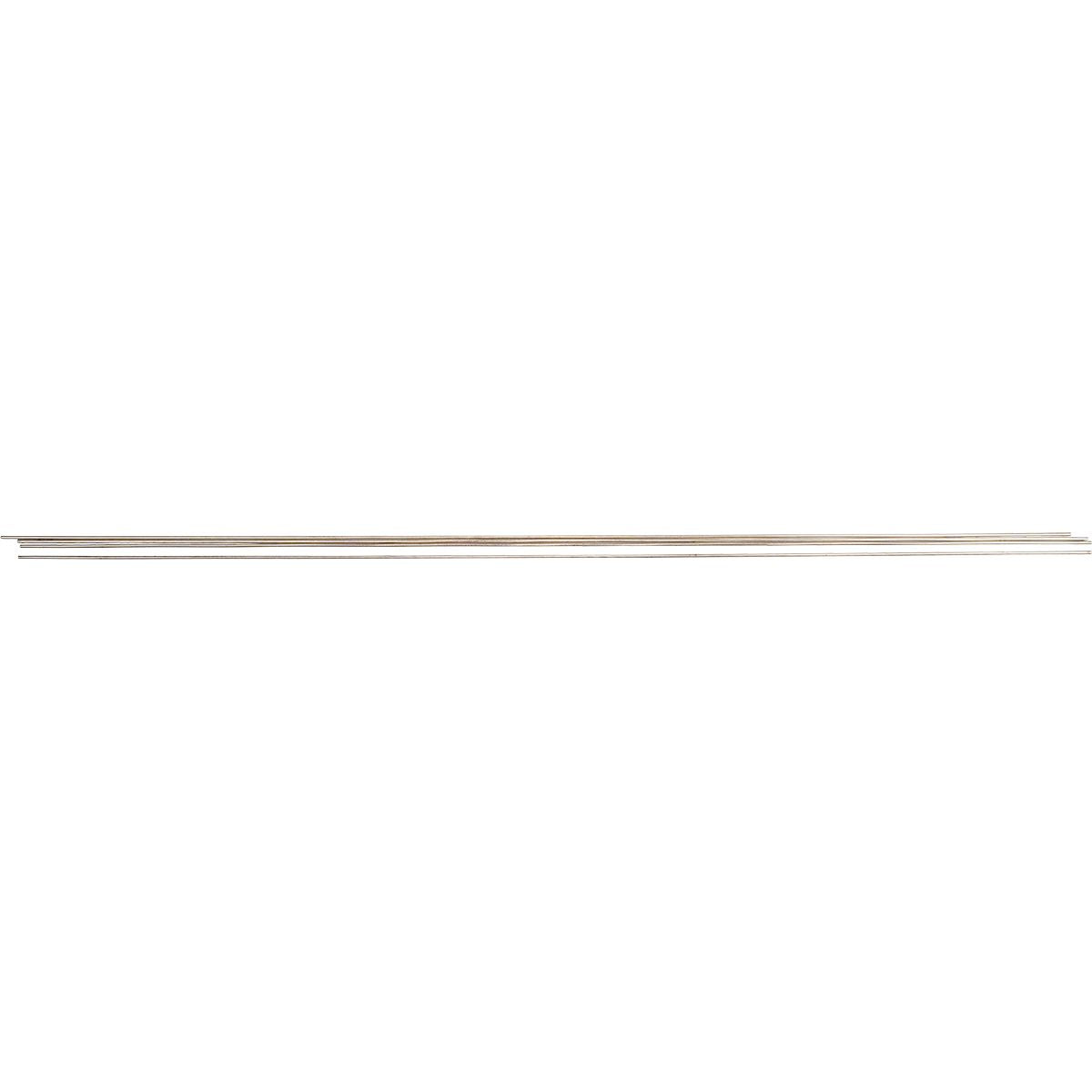

54 Medium Silver Flux Coated Brazing Rod, Metallic, 18" Length, 1/16"

(Pack of

15)

SKU:P14445 Item#: P14445

Providing maximum capillary action and the lowest melting temperatures, these high silver products waste less brazing alloy. They have the ability to join many different metals – tool steel, stainless steel, alloy steel, copper and brass alloys and many others.

Superior Advantages

• Thin flow provides excellent capillary action

• Excellent electrical conductivity

• Low melt temperatures

Cadmium-free, flux-coated

Flux Coating Color: OrangeTensile Strength: Up to 60,000 PSIBonding Temperature: 1,150°F to 1,200°F (621°C to 649°C)Recommended Flux: 950 (if needed)

Applications

• Electrical components

• Carbide tipping

• Copper coils and tubing

• Food, beverage and kitchen equipment (cadmium-free products)

Usage ProcedureFor contaminated, highly oxidized, long close fit joints where extra flux is required, use 950 Flux. Use 950 Flux for gas brazing.

Frequently Bought Together

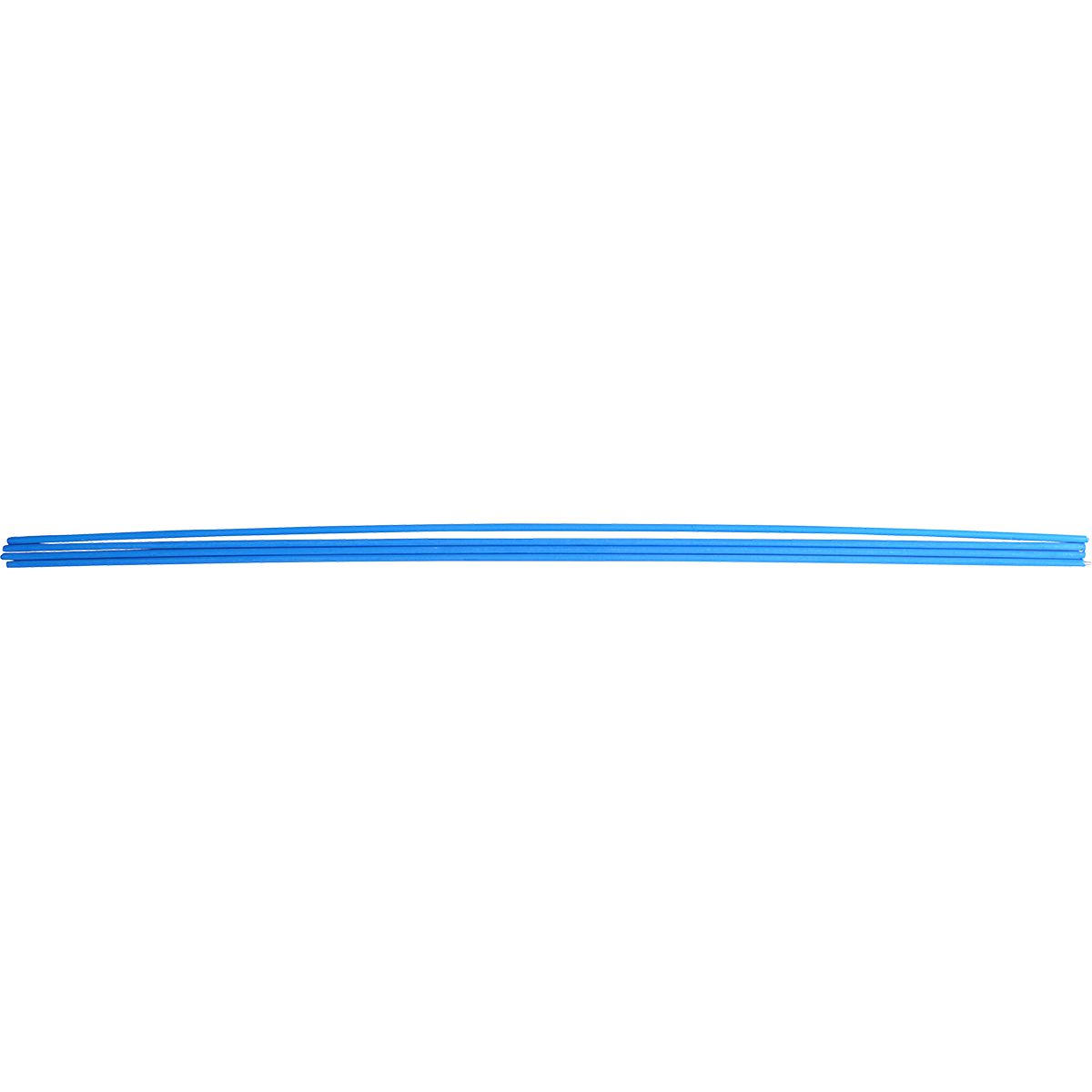

261 Blue Flux Coated General Purpose Silver Brazing Alloy 1/16X18

Couldn't load pickup availability

265 Bare Silver Free Flowing Copper Alloy .050X20

Couldn't load pickup availability

264 Bare High Silver Cadium Free Alloy 1/16x18

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 1/4"

Couldn't load pickup availability

Flat Washer Grade 12 Thru-Hardened Steel M8

Couldn't load pickup availability

PTO Pin Lock 1/4 x 2-1/2"

Couldn't load pickup availability

40 High Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

266 Pink Flux Coated Super Fast Flowing Silver Brasing Alloy 1/16X18

Couldn't load pickup availability

47 Sil-Phos Bare Brazing Rod 1/8"

Couldn't load pickup availability

344 Tool Steel TIG Wire 1/16"

Couldn't load pickup availability

Oxy-Therm Cutting Rod 3/8 x 24"

Couldn't load pickup availability

40 High Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

Product Description

Providing maximum capillary action and the lowest melting temperatures, these high silver products waste less brazing alloy. They have the ability to join many different metals – tool steel, stainless steel, alloy steel, copper and brass alloys and many others.Superior Advantages

• Thin flow provides excellent capillary action

• Excellent electrical conductivity

• Low melt temperatures

Cadmium-free, flux-coated

Flux Coating Color: OrangeTensile Strength: Up to 60,000 PSIBonding Temperature: 1,150°F to 1,200°F (621°C to 649°C)Recommended Flux: 950 (if needed)

Applications

• Electrical components

• Carbide tipping

• Copper coils and tubing

• Food, beverage and kitchen equipment (cadmium-free products)

Usage ProcedureFor contaminated, highly oxidized, long close fit joints where extra flux is required, use 950 Flux. Use 950 Flux for gas brazing.

Technical Specifications

| Item#: | P14445 |

|---|---|

| Welding Process | Brazing |

| Type | Flux Coating |

| Diameter | 1/16 " |

| Length | 18 " |

| Melting Temperature | 1150-1200 °F |

| Color | Metallic |

| Base Metal | Silver |

| Silver Content | Medium |

| Recommended Flux | F40 |

| Description | Medium Silver |

| UNSPSC #: | 23271804 |

| TAA Compliant: | Yes |

| Weight: | 0.81 lb |