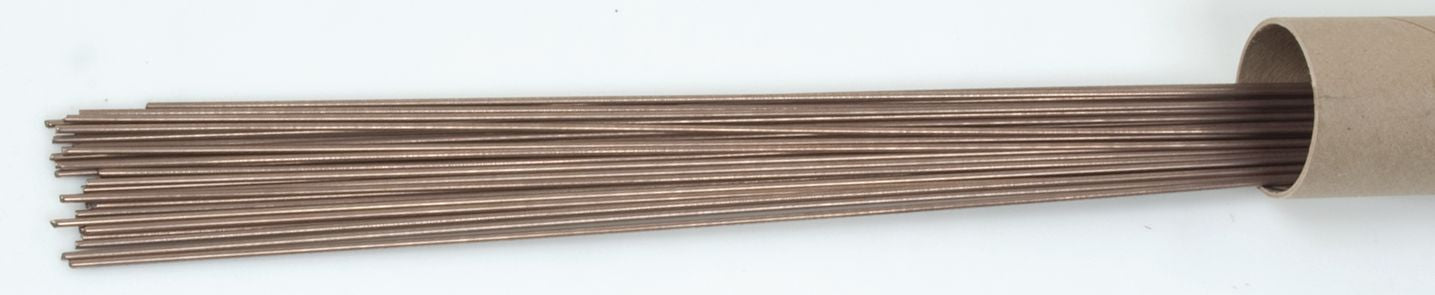

44 Bare Brazing Rod, Copper/Silver, 36"Length, 1/16" Diameter

(Pack of

2)

SKU:CW1838 Item#: CW1838

For a variety of copper and brass applications.

Superior Advantages

• High strength

• Lower cost compared to silver alloys

• Good color match

Silver Solder Substitute

Brazing Range: 1,350°F to 1,550°F (732°C to 843°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical contacts

• Copper wire splicing

• Brass and bronze fittings

• Copper pipes

• Copper to steel

Usage ProcedureUse a slightly carburizing flame to obtain a free-flowing bead. Cronabraze™ 44 does not require fusion of the base metal. For joining copper to copper, no flux is required, but with brass or bronze, F40 flux is needed for a strong, sure bond. It is recommended that 2" to 3" of distance be maintained between the flame cone and the base metal for best results.

Couldn't load pickup availability

Catalog page#: 13-30

Frequently Bought Together

266 Pink Flux Coated Super Fast Flowing Silver Brasing Alloy 1/16X18

Couldn't load pickup availability

44 Silver Bare Brazing Rod 3/32"

Couldn't load pickup availability

47 Sil-Phos Bare Brazing Rod 1/8"

Couldn't load pickup availability

44 Silver Bare Brazing Rod 3/32"

Couldn't load pickup availability

201 The Elite Blue Flux Coated Brazing Alloy 1/16

Couldn't load pickup availability

202Xl Red Flux Coated Brazing Alloy 3/16

Couldn't load pickup availability

Hex Nut Grade 5 Steel 3/8-16

Couldn't load pickup availability

Flat Washer Grade 12 Thru-Hardened Steel M10

Couldn't load pickup availability

Autobahn Ergo Magna EZ Crimper Ratcheting Terminal Crimper

Couldn't load pickup availability

163 Arc-Cut Synthetic Carbon Arc Electrode

Couldn't load pickup availability

106 Mild Steel All Purpose Electrode

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

Product Description

For a variety of copper and brass applications.Superior Advantages

• High strength

• Lower cost compared to silver alloys

• Good color match

Silver Solder Substitute

Brazing Range: 1,350°F to 1,550°F (732°C to 843°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical contacts

• Copper wire splicing

• Brass and bronze fittings

• Copper pipes

• Copper to steel

Usage ProcedureUse a slightly carburizing flame to obtain a free-flowing bead. Cronabraze™ 44 does not require fusion of the base metal. For joining copper to copper, no flux is required, but with brass or bronze, F40 flux is needed for a strong, sure bond. It is recommended that 2" to 3" of distance be maintained between the flame cone and the base metal for best results.

Technical Specifications

| Item#: | CW1838 |

|---|---|

| Welding Process | Brazing |

| Type | Bare |

| Diameter | 1/16 " |

| Length | 36 " |

| Melting Temperature | 1350-1550 °F |

| Color | Copper |

| Base Metal | Silver |

| Recommended Flux | F40 |

| Description | Copper/Brass |

| UNSPSC #: | 23271804 |

| TAA Compliant: | No |

| Weight: | 2.0 lb |