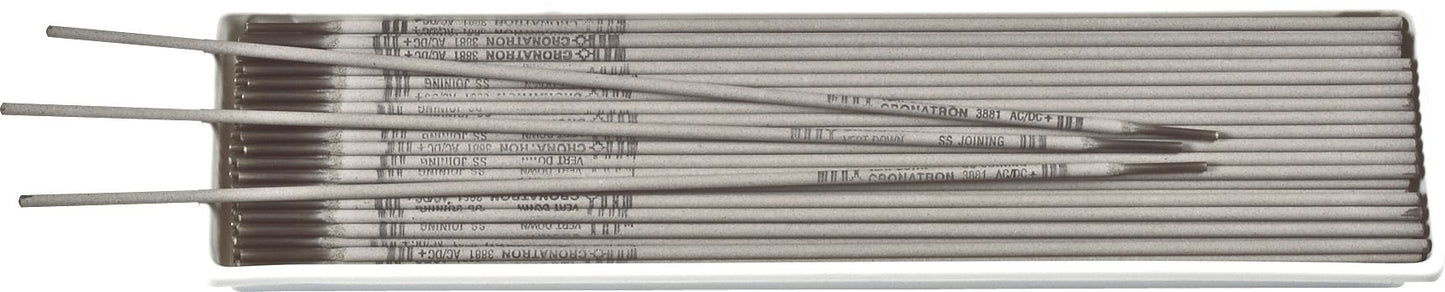

3881 Stainless Steel Stick Rod Electrode, Flux Coated, 50-75 Amps, 40% Elongation, DCRP/AC Polarity, Corrosion Resistance, 3/32"

(Pack of

5)

SKU:CW1805 Item#: CW1805

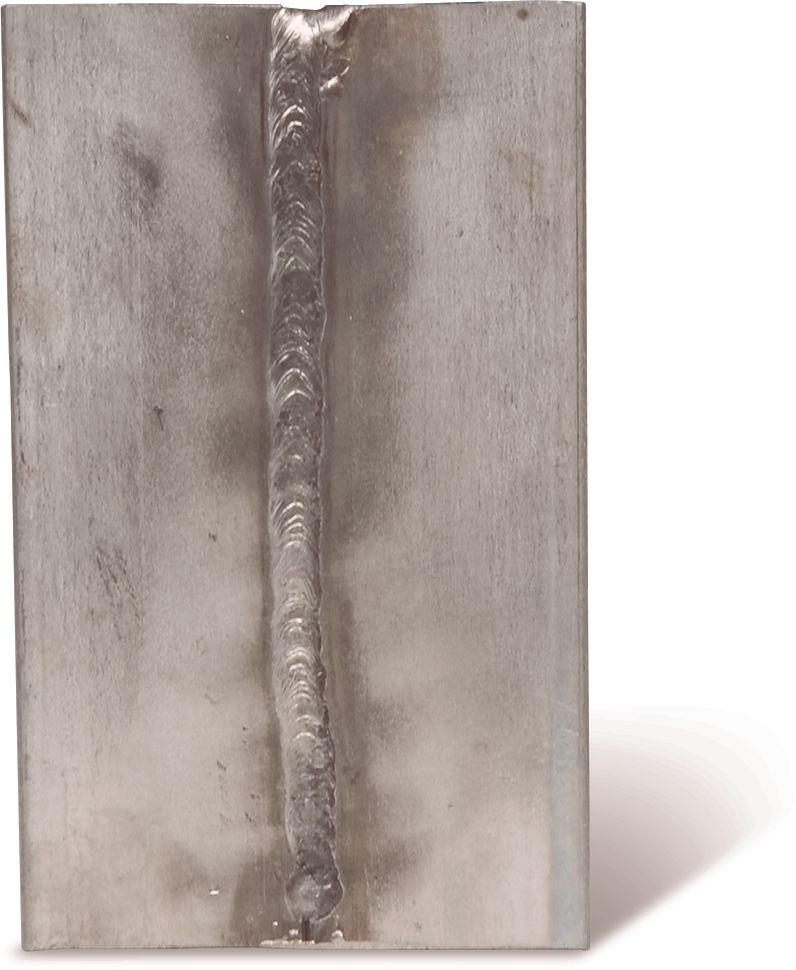

X-ray quality welds, smooth-running in all positions for joining the most common grades of stainless steels including 303, 304, 307, 308, 309, 316, 317 and the low carbon “L” version of these alloys.

Superior Advantages

• Minimal carbide precipitation

• Excellent resistance to corrosion and heat

• All-position welding reduces the need to dismantle equipment

• Easy slag removal saves time

Excellent Vertical-down and Overhead

Tensile Strength: 84,000 PSIElongation: 40%Polarity: AC or DC Reverse

Designed specifically to deposit sound X-ray quality welds in the vertical-down position.

Applications

• Piping and tubing

• Food and medical processing equipment

• Housings and impellers

• Tanks and vats

Usage Procedure:Use AC or DC reverse polarity with normal maintenance welding procedures. Surface area should be as clean as possible. However, Cronaweld™ Eagle 3881 is manufactured with special cleansing and fluxing agents to promote sound welds under most conditions. For vertical-down welding, hold a short arc and tilt the electrode 10° in the direction of travel, using a stringer bead technique.

Frequently Bought Together

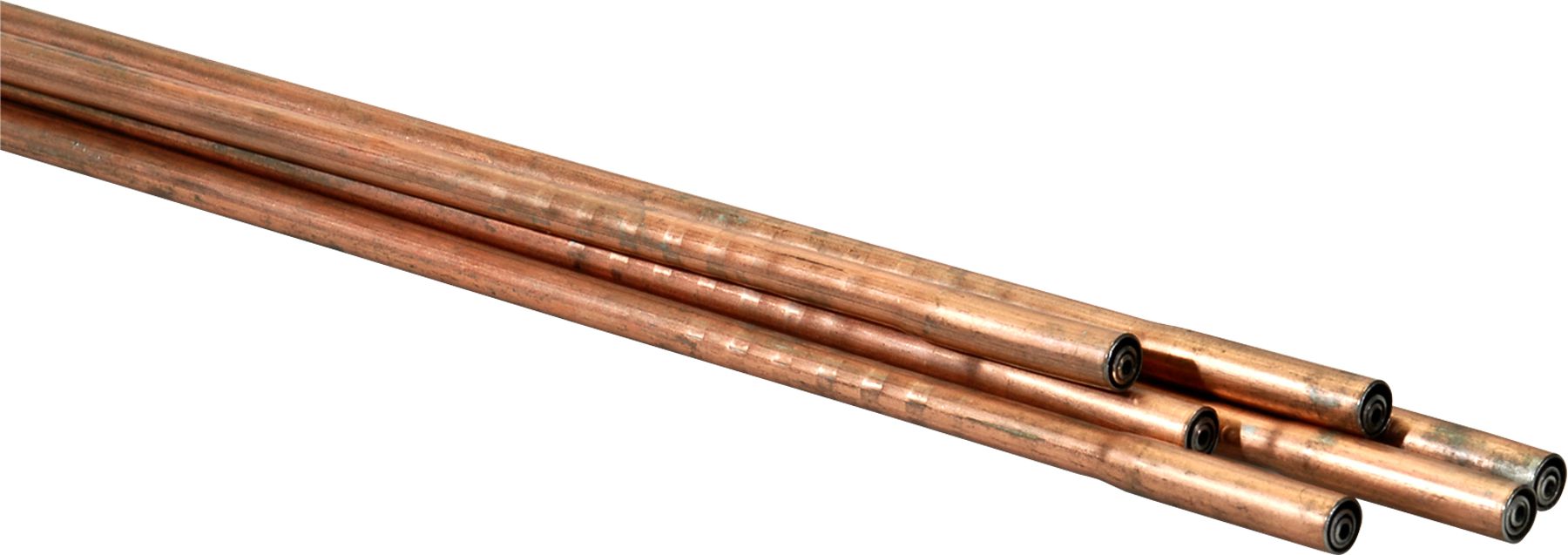

1100 Gouging and Cutting Stick Rod Electrode 5/32"

Couldn't load pickup availability

1100 Gouging and Cutting Stick Rod Electrode 3/16"

Couldn't load pickup availability

1/2" Cordless Drill Driver Charging Bundle

Couldn't load pickup availability

Hex Nut Grade 8 Alloy Steel 1/2-13

Couldn't load pickup availability

Self-Drilling Screw Hex Head 1/4-14 x 1"

Couldn't load pickup availability

Superbutt Connector 16 to 14 AWG Blue

Couldn't load pickup availability

ER316L Stainless Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

124 Stainless Steel Stick Electrode 3/32

Couldn't load pickup availability

E309L-16 Stainless Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

344 Tool Steel TIG Wire 1/16"

Couldn't load pickup availability

Oxy-Therm Cutting Rod 3/8 x 24"

Couldn't load pickup availability

40 High Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 1/8

Couldn't load pickup availability

E6010 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

345 Tool Steel TIG Wire 1/16"

Couldn't load pickup availability

Product Description

X-ray quality welds, smooth-running in all positions for joining the most common grades of stainless steels including 303, 304, 307, 308, 309, 316, 317 and the low carbon “L” version of these alloys.Superior Advantages

• Minimal carbide precipitation

• Excellent resistance to corrosion and heat

• All-position welding reduces the need to dismantle equipment

• Easy slag removal saves time

Excellent Vertical-down and Overhead

Tensile Strength: 84,000 PSIElongation: 40%Polarity: AC or DC Reverse

Designed specifically to deposit sound X-ray quality welds in the vertical-down position.

Applications

• Piping and tubing

• Food and medical processing equipment

• Housings and impellers

• Tanks and vats

Usage Procedure:Use AC or DC reverse polarity with normal maintenance welding procedures. Surface area should be as clean as possible. However, Cronaweld™ Eagle 3881 is manufactured with special cleansing and fluxing agents to promote sound welds under most conditions. For vertical-down welding, hold a short arc and tilt the electrode 10° in the direction of travel, using a stringer bead technique.

Technical Specifications

| Item#: | CW1805 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 3/32 " |

| Tensile Strength | 84,000 PSI |

| Elongation | 40 % |

| Base Metal | Stainless Steel |

| Polarity | DCRP/AC |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.0 lb |

Product Restrictions