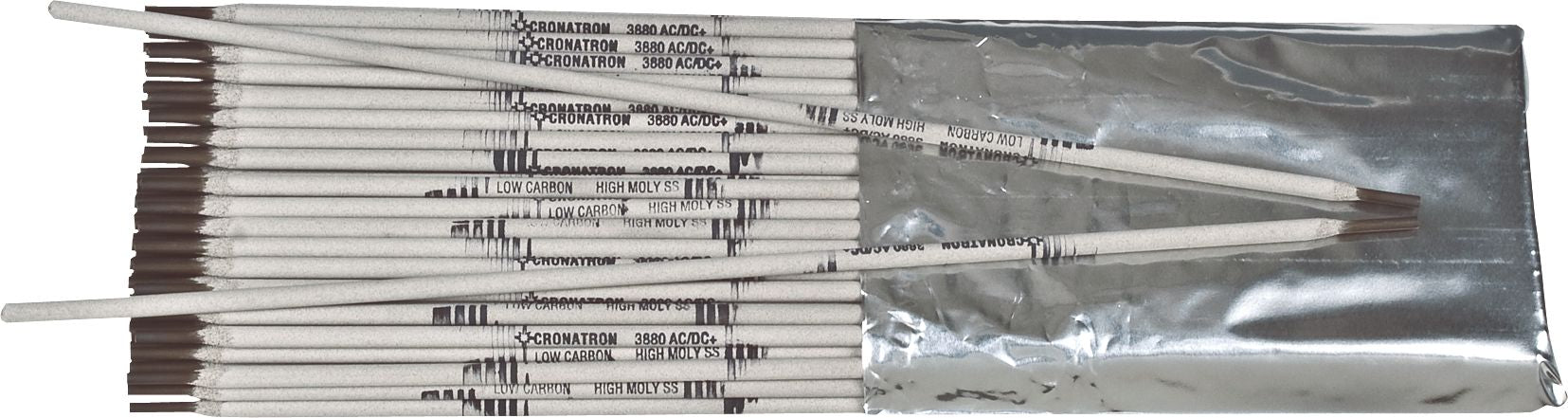

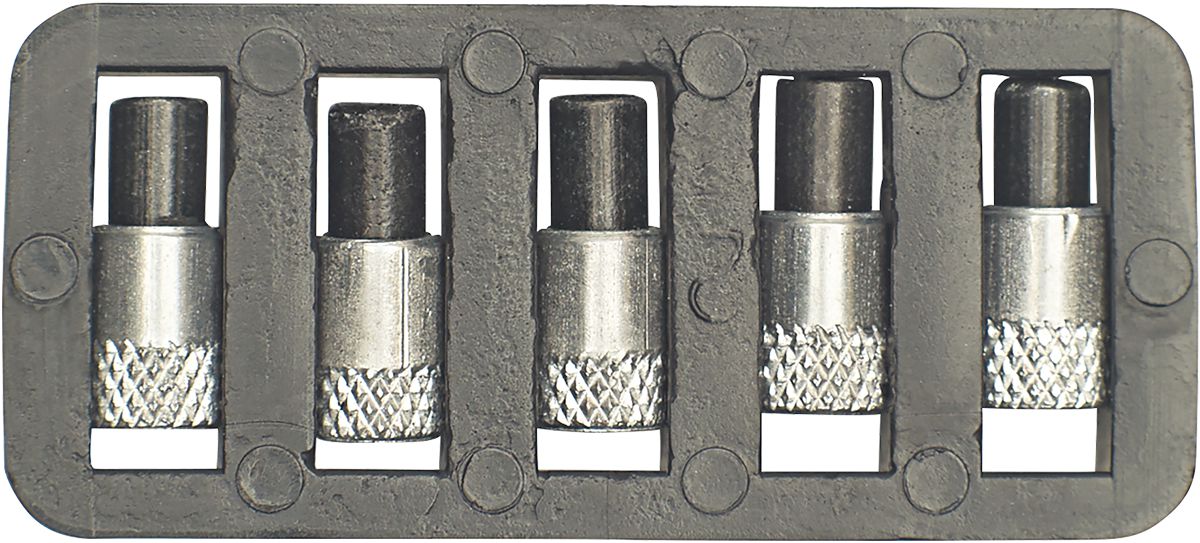

3881 Stainless Steel Stick Rod Electrode, Flux Coated, 75 to 90 Amps, 40% Elongation, DCRP/AC Polarity, Corrosion Resistant, 1/8"

(Pack of

5)

SKU:CW1806 Item#: CW1806

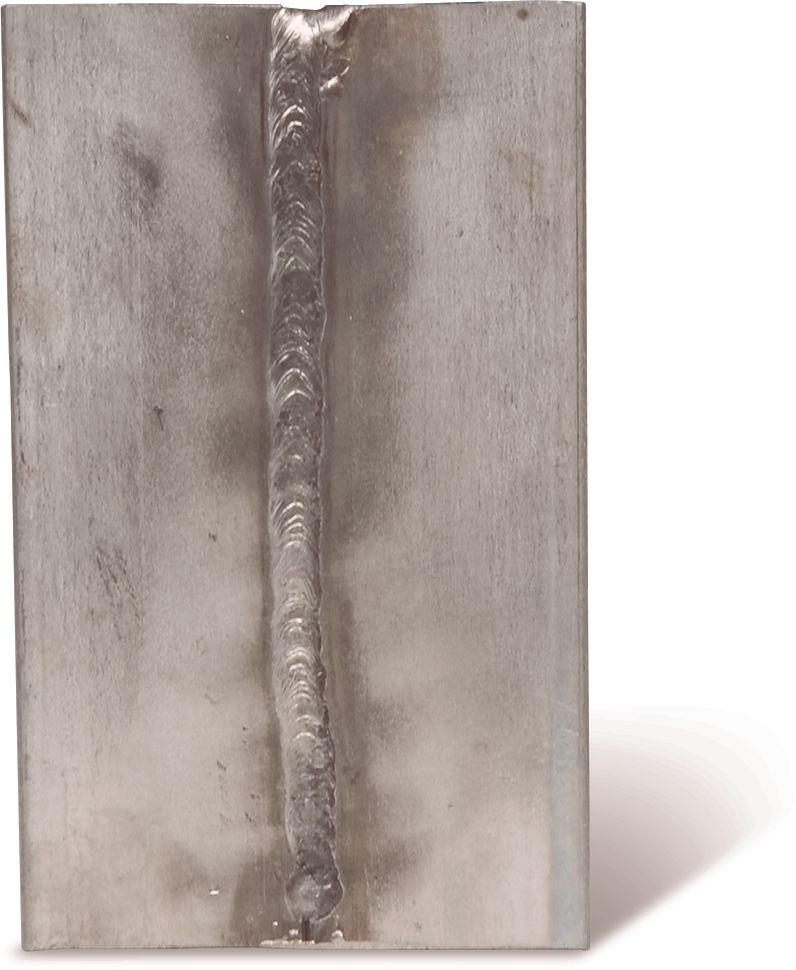

Achieve precision and durability with the 3881 Stainless Steel Stick Rod Electrode, engineered for stainless steel fabrication specialists. Delivering X-ray quality welds, this electrode runs smoothly in all positions, making it perfect for joining popular grades like 303, 304, 308, and more—including their low-carbon “L” versions. Its superior resistance to corrosion and heat ensures long-lasting results, while minimal carbide precipitation protects the integrity of your welds. Designed for effortless all-position welding, it reduces the need to dismantle industrial equipment, saving you time and effort. Ideal for applications such as piping, medical equipment, tanks, and more, the 3881 electrode combines efficiency and reliability for your most demanding projects.

• Designed specifically to deposit sound X-ray quality welds in the vertical-down position

• Tensile Strength: 84,000 PSIElongation: 40%Polarity: AC or DC Reverse

• Excellent Vertical-down and Overhead

• Minimal carbide precipitation

• Excellent resistance to corrosion and heat

• All-position welding reduces the need to dismantle equipment

• Easy slag removal saves time

Excellent Vertical-down and Overhead

Applications

• Piping and tubing

• Food and medical processing equipment

• Housings and impellers

• Tanks and vats

Usage Procedure:Use AC or DC reverse polarity with normal maintenance welding procedures. Surface area should be as clean as possible. However, Cronaweld™ Eagle 3881 is manufactured with special cleansing and fluxing agents to promote sound welds under most conditions. For vertical-down welding, hold a short arc and tilt the electrode 10° in the direction of travel, using a stringer bead technique.

Frequently Bought Together

Torrent 500 115 ETL Partswasher

Couldn't load pickup availability

Torrent 700 115V Partswasher

Couldn't load pickup availability

1101 Aqueous Parts Cleaning Solution

Couldn't load pickup availability

Nylon Cable Tie 8" Black

Couldn't load pickup availability

Nylon Cable Tie 15.25" Black

Couldn't load pickup availability

Nylon Cable Tie 11.75" Black

Couldn't load pickup availability

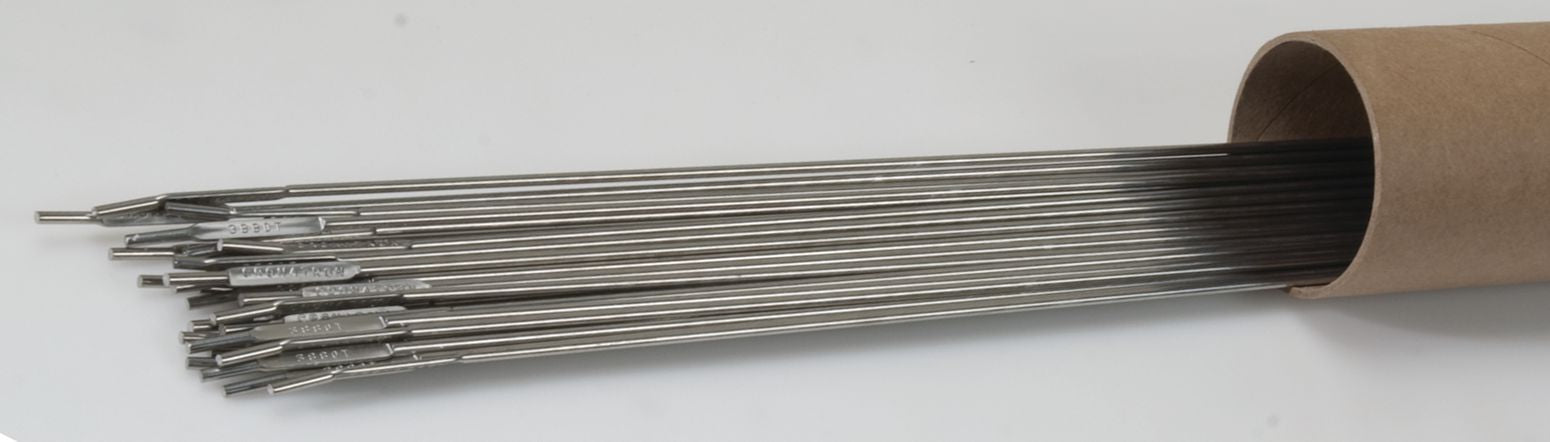

3880 Stainless Steel TIG Wire 3/32"

Couldn't load pickup availability

3880 Stainless Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

383 Stainless Steel TIG Wire 1/16"

Couldn't load pickup availability

Oxy Acetylene Fuel Gas Single Flint Striker

Couldn't load pickup availability

Flat Soapstone 1/2"

Couldn't load pickup availability

Oxy Acetylene Fuel Gas Single Replacement Flint

Couldn't load pickup availability

333 Dissimilar Steel TIG Wire 1/16"

Couldn't load pickup availability

ER4043 Aluminum MIG Welding Wire 0.035"

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

Product Description

Achieve precision and durability with the 3881 Stainless Steel Stick Rod Electrode, engineered for stainless steel fabrication specialists. Delivering X-ray quality welds, this electrode runs smoothly in all positions, making it perfect for joining popular grades like 303, 304, 308, and more—including their low-carbon “L” versions. Its superior resistance to corrosion and heat ensures long-lasting results, while minimal carbide precipitation protects the integrity of your welds. Designed for effortless all-position welding, it reduces the need to dismantle industrial equipment, saving you time and effort. Ideal for applications such as piping, medical equipment, tanks, and more, the 3881 electrode combines efficiency and reliability for your most demanding projects.• Designed specifically to deposit sound X-ray quality welds in the vertical-down position

• Tensile Strength: 84,000 PSIElongation: 40%Polarity: AC or DC Reverse

• Excellent Vertical-down and Overhead

• Minimal carbide precipitation

• Excellent resistance to corrosion and heat

• All-position welding reduces the need to dismantle equipment

• Easy slag removal saves time

Excellent Vertical-down and Overhead

Applications

• Piping and tubing

• Food and medical processing equipment

• Housings and impellers

• Tanks and vats

Usage Procedure:Use AC or DC reverse polarity with normal maintenance welding procedures. Surface area should be as clean as possible. However, Cronaweld™ Eagle 3881 is manufactured with special cleansing and fluxing agents to promote sound welds under most conditions. For vertical-down welding, hold a short arc and tilt the electrode 10° in the direction of travel, using a stringer bead technique.

Technical Specifications

| Item#: | CW1806 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 1/8 " |

| Tensile Strength | 84,000 PSI |

| Elongation | 40 % |

| Base Metal | Stainless Steel |

| Polarity | DCRP/AC |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.35 lb |

Product Restrictions