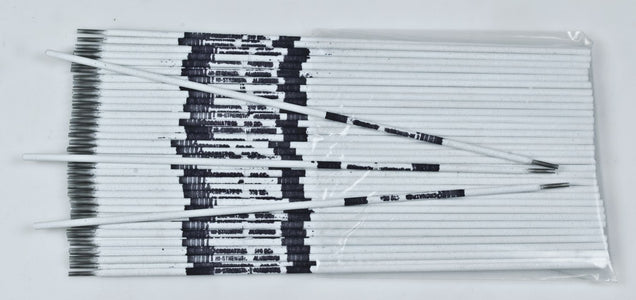

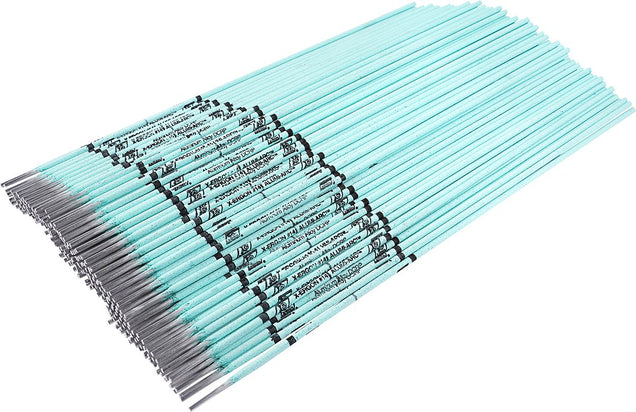

510 Aluminum TIG Wire, Solid, 100% Ar Shielding Gas, AC High Frequency Polarity, 36" Length, Quiet Arc, 1/8"

(Pack of

2)

SKU:CW1014 Item#: CW1014

Highly versatile alloys for all weldable types of aluminum including sheet, forgings, extrusions and castings.

Superior Advantages

• Stable, quiet arc with no undercutting

• Good corrosion resistance

Tensile Strength: 35,000 PSIPolarity: AC/High FrequencyGas: Argon/Helium

Usage ProcedureBevel heavy sections to allow 100% weld metal penetration. Sprinkle F56 flux into the joint area. Broadly heat area to be brazed with a large, soft and slightly carburizing flame to about 1,100°F (593°C). Heat the base metal until flux flows freely. The alloy will then begin to wet the base metal. Deposit the 510T to fill the joint. Flux residue may be removed with warm water and a brush.

Frequently Bought Together

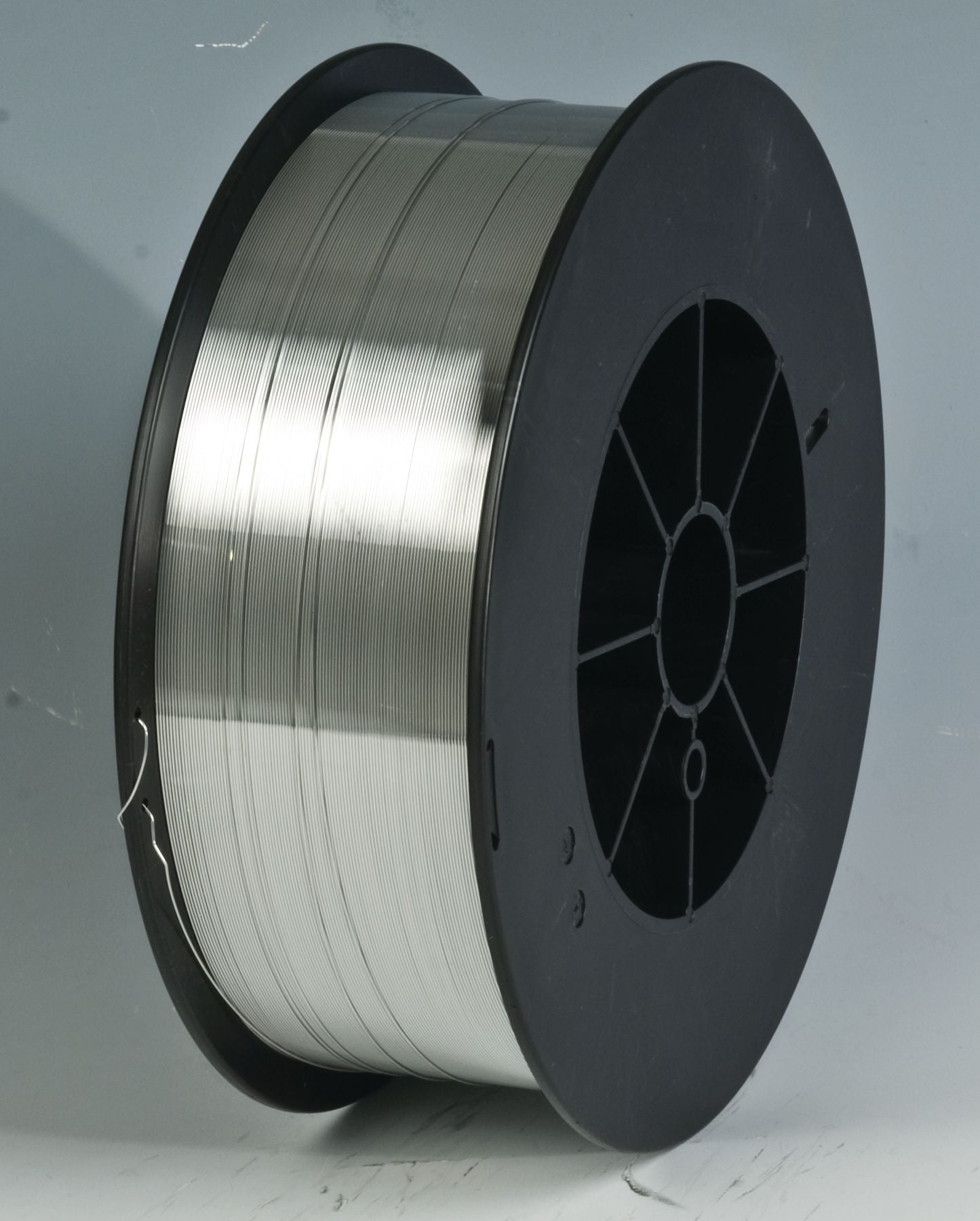

510 Aluminum MIG Welding Wire 0.035"

Couldn't load pickup availability

ER5356 Aluminum MIG Welding Wire 0.0625"

Couldn't load pickup availability

510 Aluminum MIG Welding Wire 3/64"

Couldn't load pickup availability

Nylon Cable Tie 15.5" Black

Couldn't load pickup availability

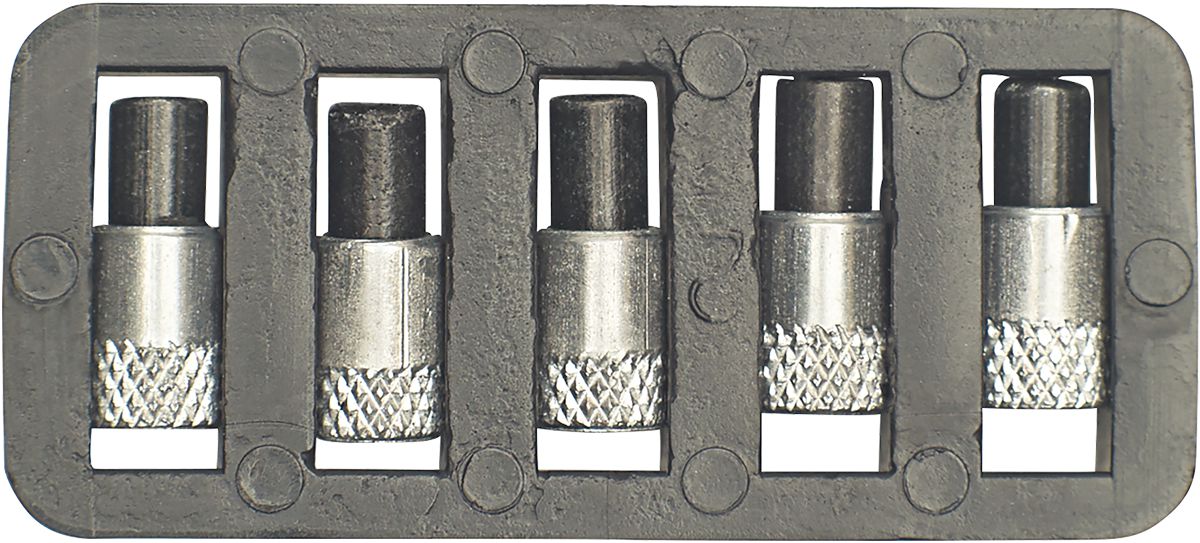

Butt Connector 16 to 14 AWG Clear

Couldn't load pickup availability

Butt Connector 22 to 18 AWG Clear

Couldn't load pickup availability

Oxy Acetylene Fuel Gas Single Replacement Flint

Couldn't load pickup availability

333 Dissimilar Steel TIG Wire 1/16"

Couldn't load pickup availability

176 Extreme Abrasion With Impact 1/4X18IN

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

Product Description

Highly versatile alloys for all weldable types of aluminum including sheet, forgings, extrusions and castings.Superior Advantages

• Stable, quiet arc with no undercutting

• Good corrosion resistance

Tensile Strength: 35,000 PSIPolarity: AC/High FrequencyGas: Argon/Helium

Usage ProcedureBevel heavy sections to allow 100% weld metal penetration. Sprinkle F56 flux into the joint area. Broadly heat area to be brazed with a large, soft and slightly carburizing flame to about 1,100°F (593°C). Heat the base metal until flux flows freely. The alloy will then begin to wet the base metal. Deposit the 510T to fill the joint. Flux residue may be removed with warm water and a brush.

Technical Specifications

| Item#: | CW1014 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | 1/8 " |

| Length | 36 " |

| Tensile Strength | 35,000 PSI |

| Base Metal | Aluminum |

| Shielding Gas | 100% Ar |

| Polarity | AC High Freq |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 2.0 lb |

Product Restrictions