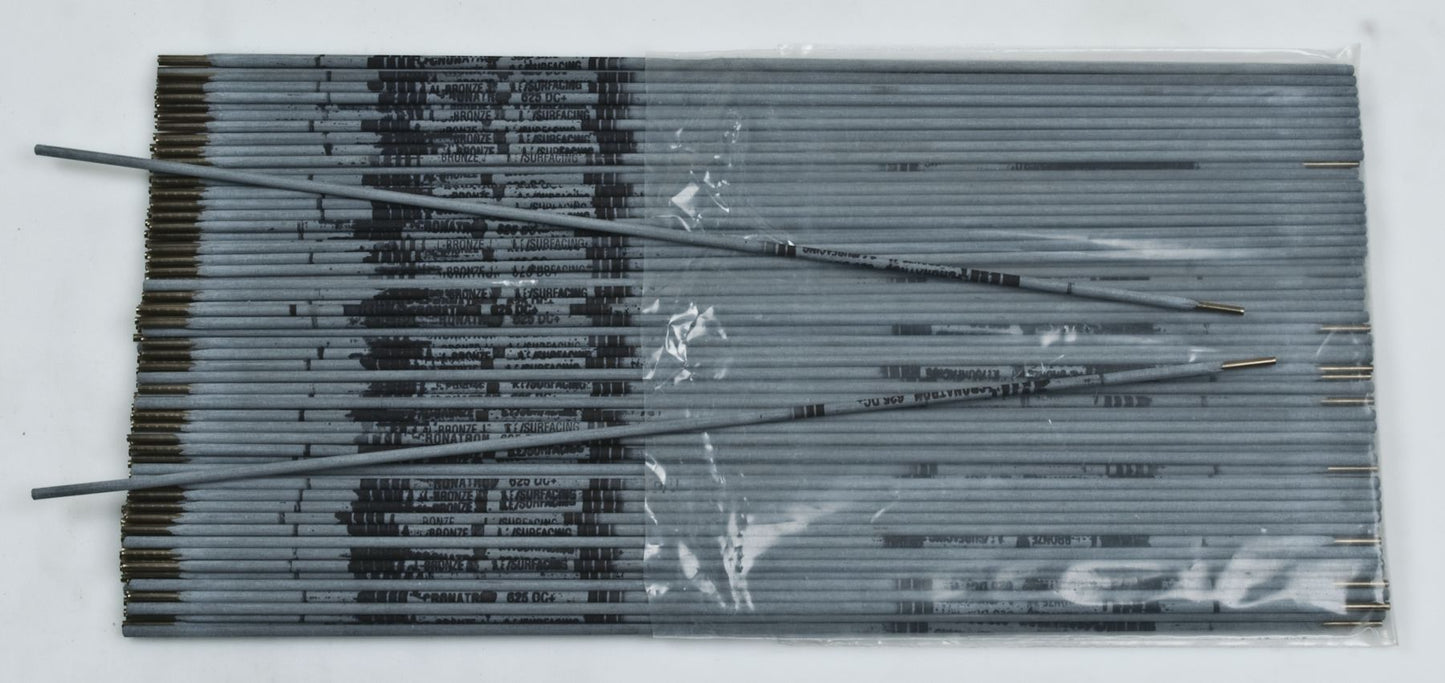

625 Copper and Brass Stick Rod Electrode, Flux Coated, 50 to 75 Amps, DCRP Polarity, Easy Arc Control, 3/32"

(Pack of

5)

SKU:CW1859 Item#: CW1859

Welds most ferrous and non-ferrous metals and joins most combinations of dissimilar metals (except white metals).

Superior Advantages

• Tough, crack-free, machinable welds

• Easy arc control with little preheat

• High frictional wear resistance

• High strength

Tensile Strength: 110,000 PSIHardness: Rc 21-23Polarity: DC Reverse

Typical Applications

• Brass, bronze or cast iron to steel

•Gear teeth, valves and castings

• Impellers, cams and shafts

Usage ProcedureUse DC reverse polarity. Clean surfaces of grease, rust or scale. Use short arc with weave or stringer bead. No preheating required, except on heavy sections: 500°F (260°C) steel; 900°F (482°C) copper. For TIG use direct current straight polarity (electrode–). Clean surfaces of grease, rust, scale, etc. Use pure argon gas or a mixture of argon/helium for heavy sections. Set the flow rate at 15 to 20 CFH. For best results, use a gas lens collet body. Amperage will depend on ba

Frequently Bought Together

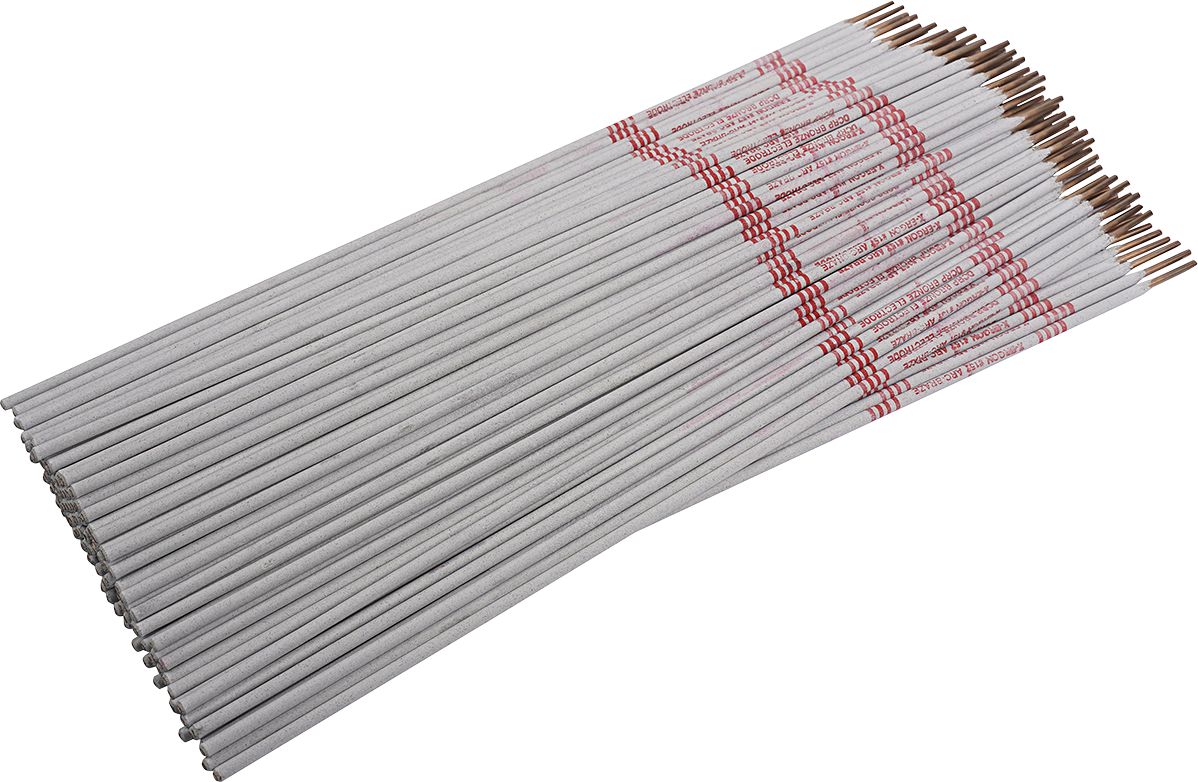

157 Bronze Stick Electrode 3/32

Couldn't load pickup availability

157T Premium Bronze Solid Tig Wire 3/32X36

Couldn't load pickup availability

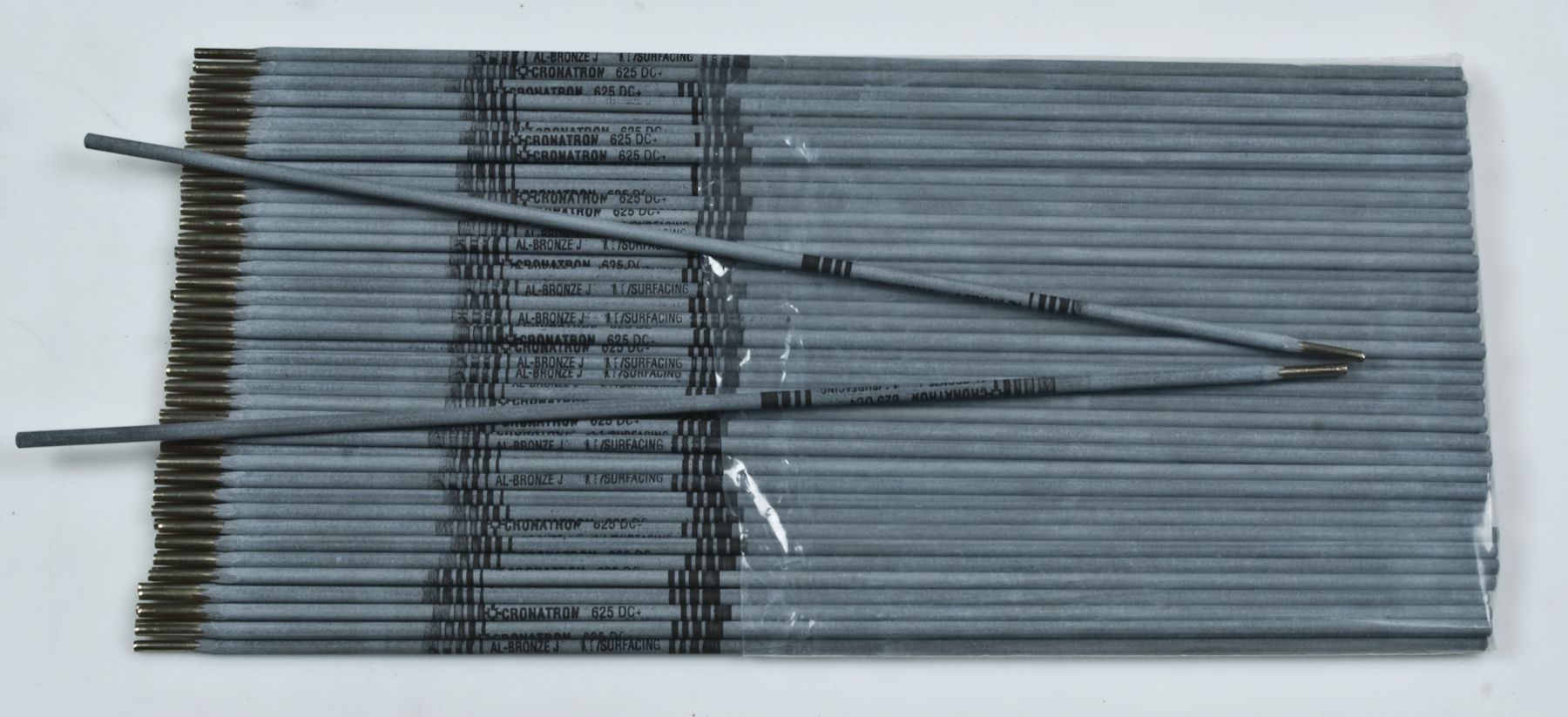

625 Copper and Brass Stick Rod Electrode 1/8"

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 1/4"

Couldn't load pickup availability

Butt Connector 16 to 14 AWG Blue

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 3/8"

Couldn't load pickup availability

Rosin Core Solder 0.032"

Couldn't load pickup availability

Solid Solder 1/32"

Couldn't load pickup availability

22-50 MIG Welding Nozzle 1/2"

Couldn't load pickup availability

321 Mild and Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

163 Arc-Cut Synthetic Carbon Arc Electrode

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

Product Description

Welds most ferrous and non-ferrous metals and joins most combinations of dissimilar metals (except white metals).Superior Advantages

• Tough, crack-free, machinable welds

• Easy arc control with little preheat

• High frictional wear resistance

• High strength

Tensile Strength: 110,000 PSIHardness: Rc 21-23Polarity: DC Reverse

Typical Applications

• Brass, bronze or cast iron to steel

•Gear teeth, valves and castings

• Impellers, cams and shafts

Usage ProcedureUse DC reverse polarity. Clean surfaces of grease, rust or scale. Use short arc with weave or stringer bead. No preheating required, except on heavy sections: 500°F (260°C) steel; 900°F (482°C) copper. For TIG use direct current straight polarity (electrode–). Clean surfaces of grease, rust, scale, etc. Use pure argon gas or a mixture of argon/helium for heavy sections. Set the flow rate at 15 to 20 CFH. For best results, use a gas lens collet body. Amperage will depend on ba

Technical Specifications

| Item#: | CW1859 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 3/32 " |

| Tensile Strength | 110,000 PSI |

| Base Metal | Copper/Brass |

| Hardness | 21-23 HRC |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.2 lb |

Product Restrictions