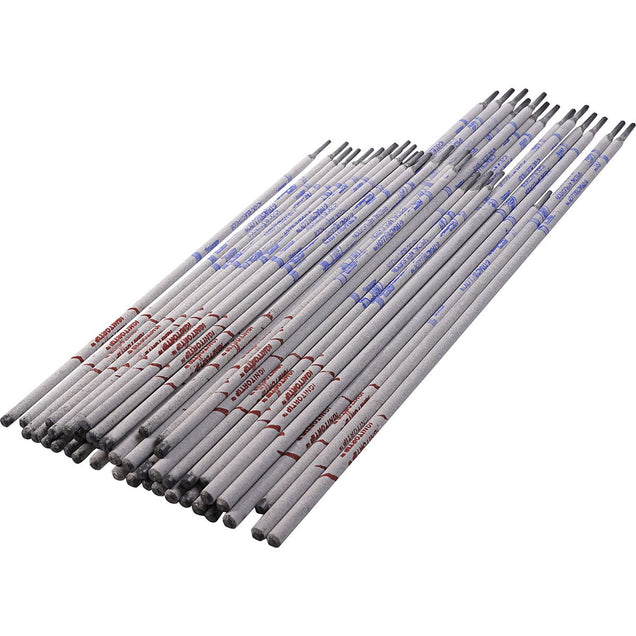

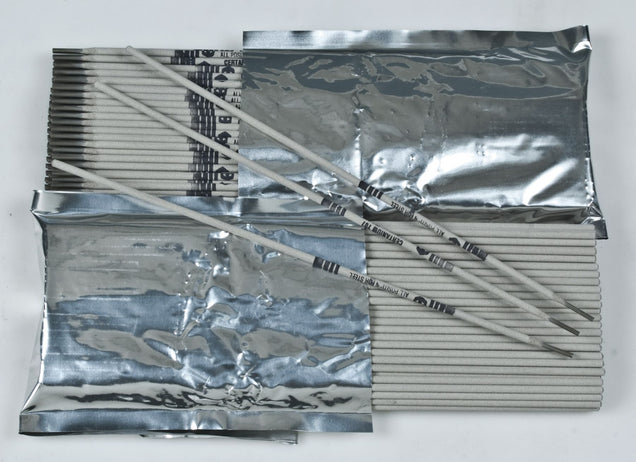

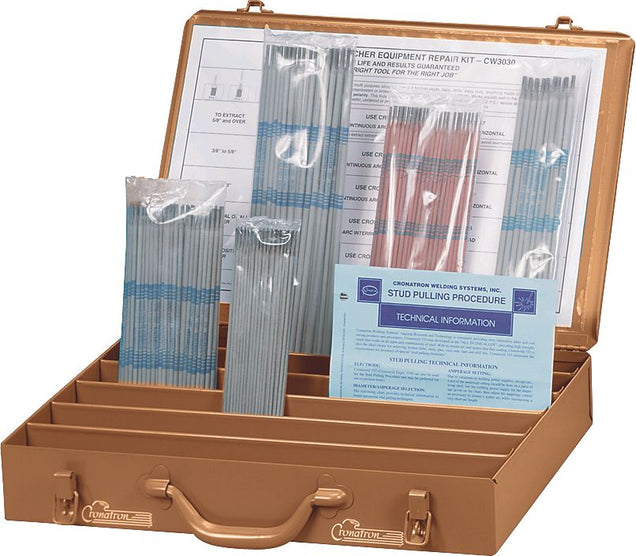

2 Pound Jobber Pack Assortment 1/8 Blue Lightning And 3/32 Blue Lightning Duplex Alloy For Disimilar Metals Polarity Dcep/Ac

(Pack of

1)

SKU:EG10094002 Item#: EG10094002

Blue Lightning is a tough duplex alloy designed for dissimilar welding applications of ferrous metals (except cast iron).

• AC Welding — special flux coating enhances operability on buzz boxes and DC inverter welders

• High strength — resistant to heat and corrosion, but still machinable

• High elongation — tough welds stand up to impact and shock

• Versatile — welds steel, stainless steel, manganese steel, HY steels, alloy steels, tool steels and nickel alloys to steel and dissimilar combinations of these alloys

• All-position welding and easy slag removal

• Tensile strength:– as deposited: 95,000 psi/655 MPa– work hardened: up to 130,000 psi/896 MPa

• Hardness:– as deposited: 93 Rb– work hardened: up to 35 Rc

• Elongation: 30%

• Machinability: Excellent

• Heat resistance: Good

• Corrosion resistance: Good

• Current: DCEP (DC+) or AC

Remove defective metal by grinding or gouging with Arc-Prep #161 electrode. Bevel heavy sections before welding. Use AC or DCEP (DC+) current. Use a contact or a minimum arc length with a weave or stringer bead technique. Preheat should be used when the base metal requires it. For vertical-up welds reduce amperage slightly and use a modified weave technique. Chip the slag between multipass welds. Allow to cool slowly.

Frequently Bought Together

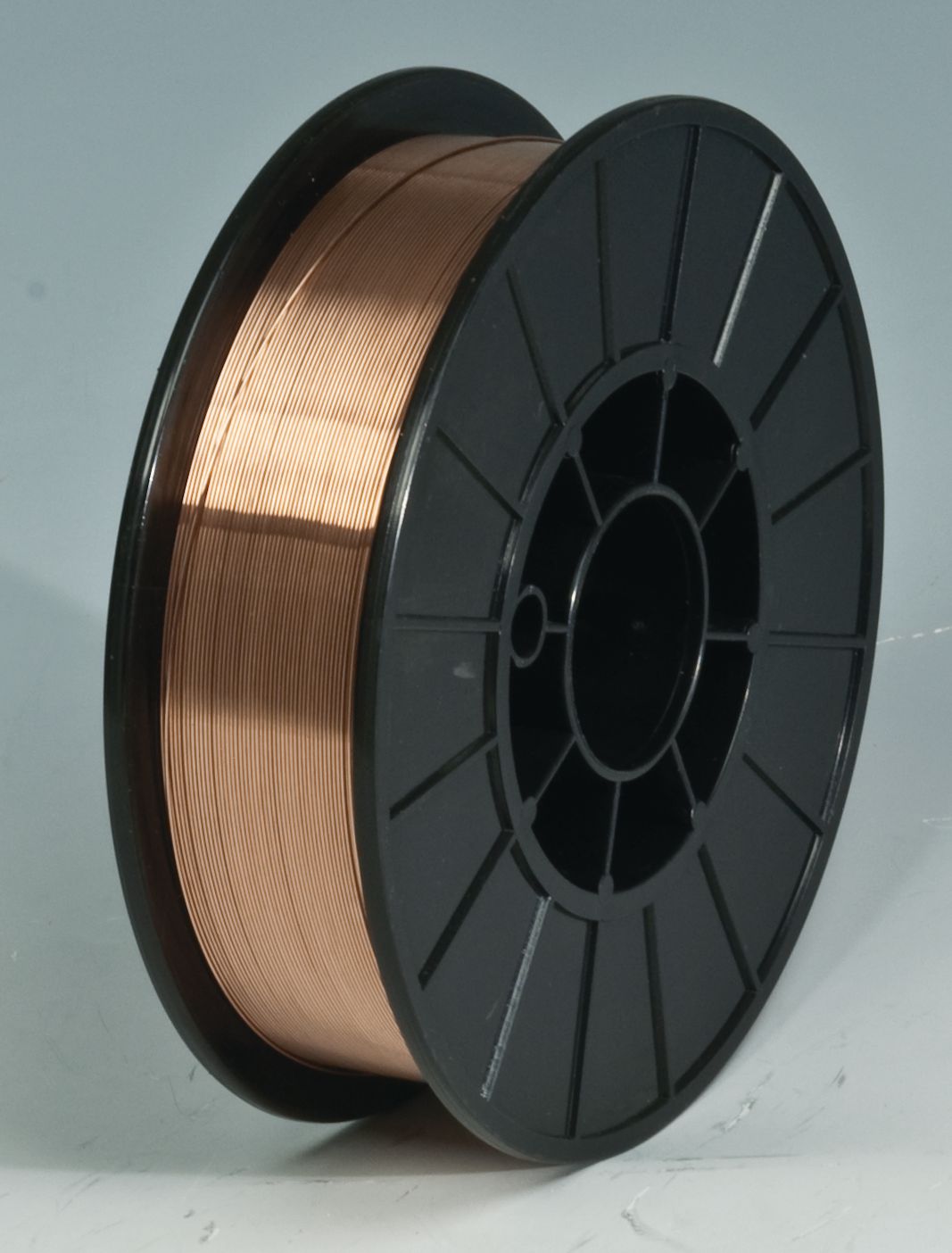

333 Dissimilar Steel MIG Welding Wire 0.045"

Couldn't load pickup availability

333 Dissimilar Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

333 Dissimilar Steel Stick Rod Electrode 5/32"

Couldn't load pickup availability

SAE J995C Locknut with Nylon Insert Grade 8 3/8-16

Couldn't load pickup availability

IFI 100/107 Top Locknut Grade C 5/8-11

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 1/4"

Couldn't load pickup availability

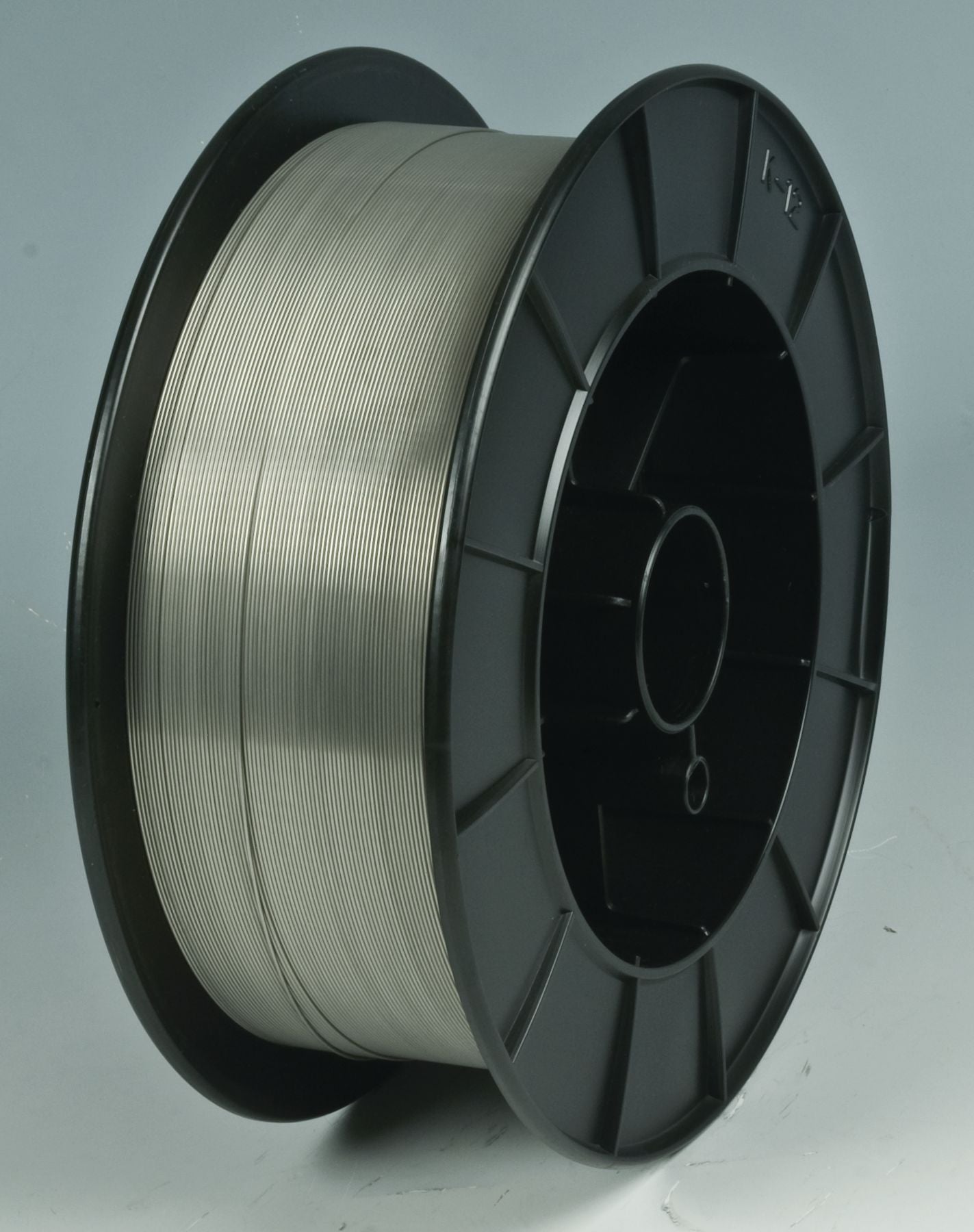

344 Tool Steel TIG Wire 1/16"

Couldn't load pickup availability

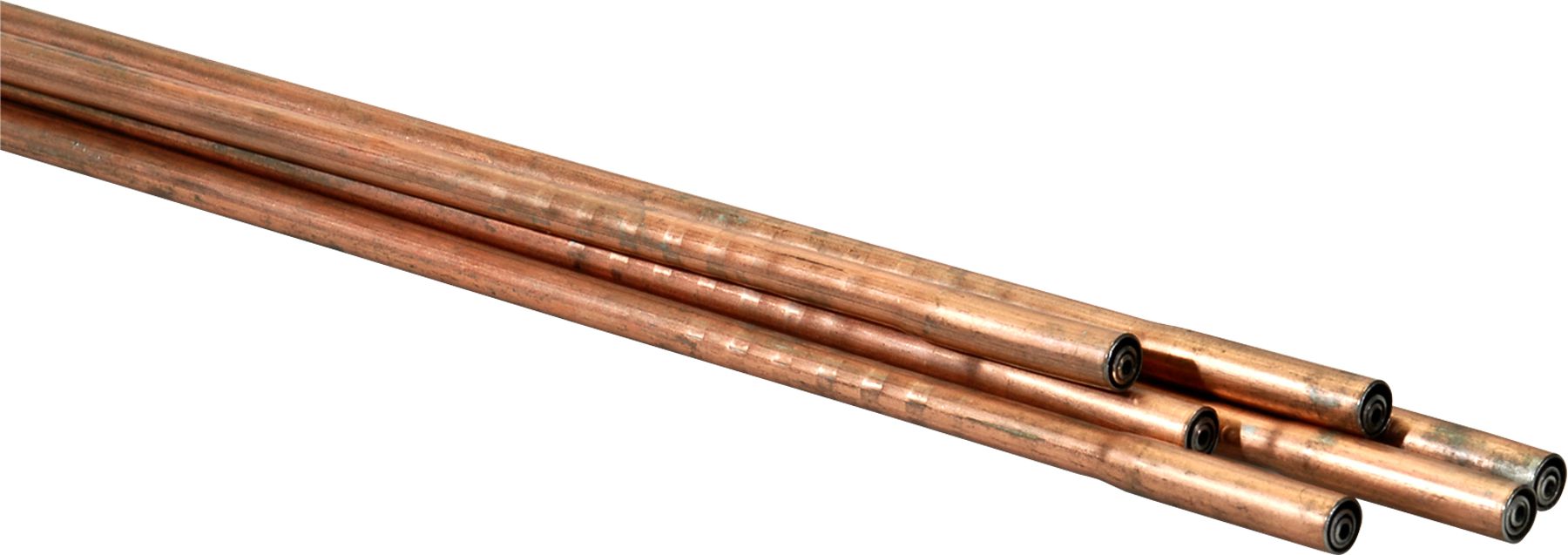

Oxy-Therm Cutting Rod 3/8 x 24"

Couldn't load pickup availability

40 High Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

E6013 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

331 Mild and Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

Product Description

Blue Lightning is a tough duplex alloy designed for dissimilar welding applications of ferrous metals (except cast iron).• AC Welding — special flux coating enhances operability on buzz boxes and DC inverter welders

• High strength — resistant to heat and corrosion, but still machinable

• High elongation — tough welds stand up to impact and shock

• Versatile — welds steel, stainless steel, manganese steel, HY steels, alloy steels, tool steels and nickel alloys to steel and dissimilar combinations of these alloys

• All-position welding and easy slag removal

• Tensile strength:– as deposited: 95,000 psi/655 MPa– work hardened: up to 130,000 psi/896 MPa

• Hardness:– as deposited: 93 Rb– work hardened: up to 35 Rc

• Elongation: 30%

• Machinability: Excellent

• Heat resistance: Good

• Corrosion resistance: Good

• Current: DCEP (DC+) or AC

Remove defective metal by grinding or gouging with Arc-Prep #161 electrode. Bevel heavy sections before welding. Use AC or DCEP (DC+) current. Use a contact or a minimum arc length with a weave or stringer bead technique. Preheat should be used when the base metal requires it. For vertical-up welds reduce amperage slightly and use a modified weave technique. Chip the slag between multipass welds. Allow to cool slowly.

Technical Specifications

| Item#: | EG10094002 |

|---|---|

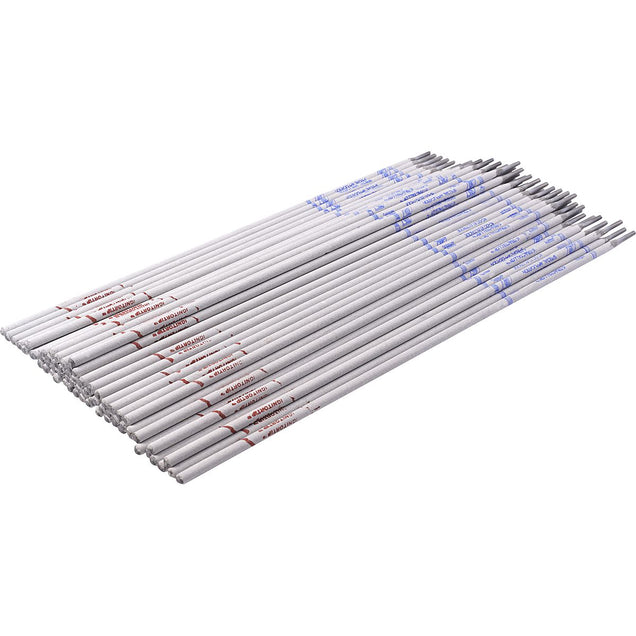

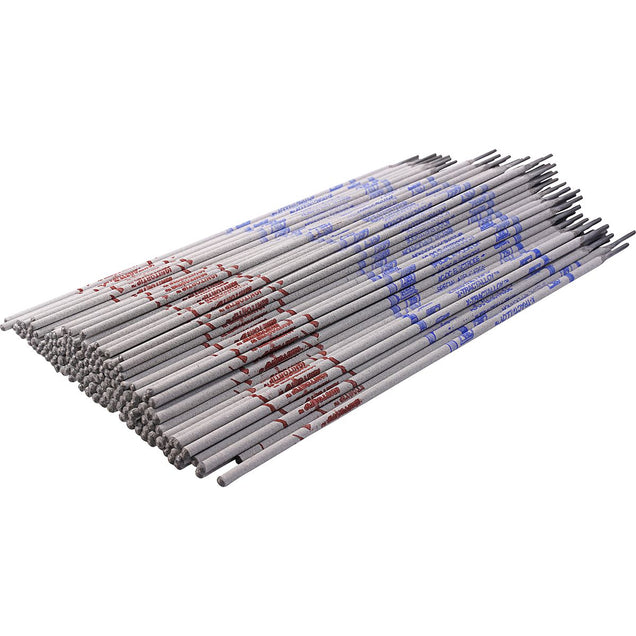

| Welding Process | Stick |

| Type | Electrode |

| Diameter | 1/8 " |

| Tensile Strength | 130,000 PSI |

| Elongation | 30 % |

| Hardness | 35 HRC |

| Polarity | DCEP |

| Total | 2 lb |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 2.17 lb |