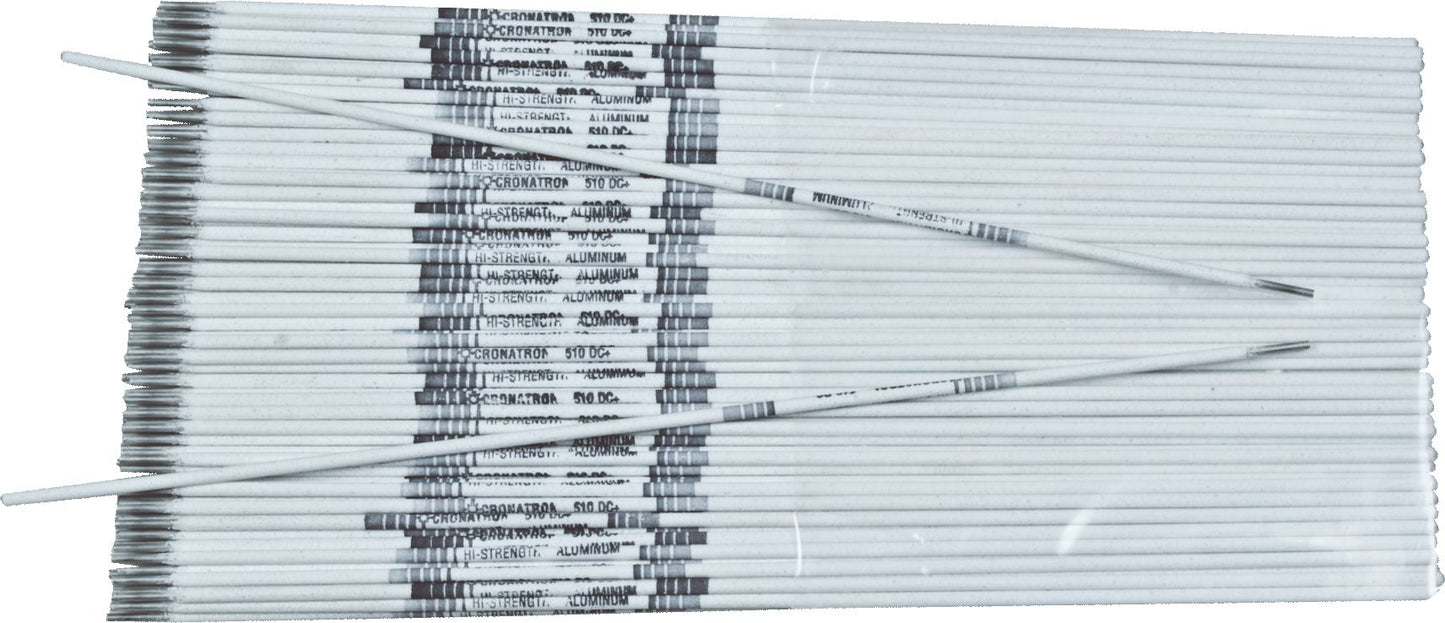

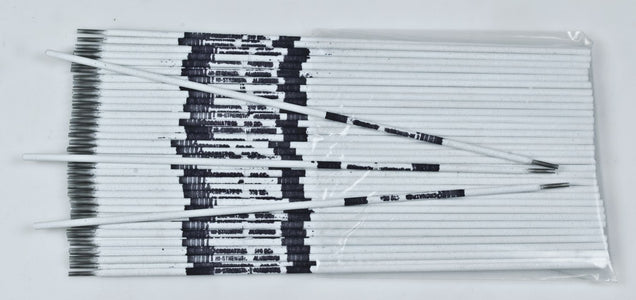

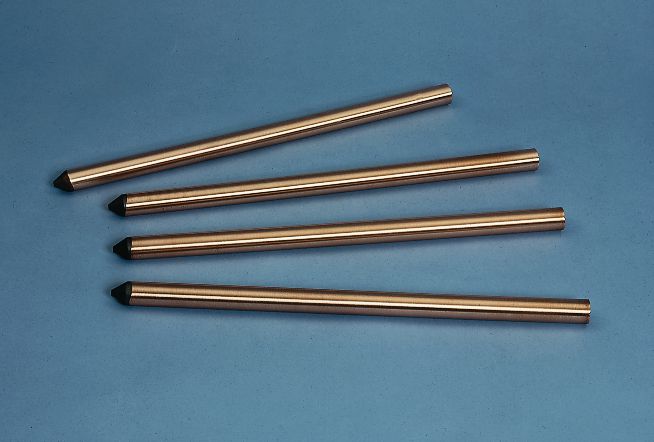

510 Aluminum Stick Rod Electrode, Flux Coated, 55 to 80 Amps, DCRP Polarity, Good Corrosion Resistance, Stable, Quiet Arc, 3/32"

(Pack of

2)

SKU:CW1826 Item#: CW1826

Highly versatile alloys for all weldable types of aluminum including sheet, forgings, extrusions and castings.

Superior Advantages

• Stable, quiet arc with no undercutting

• Good corrosion resistance

Tensile Strength: 35,000 PSIPolarity: DC Reverse

Usage ProcedureMaintain the shortest arc possible, using DC reverse polarity only. On large heavy sections, preheating to 400°F (204°C) will produce faster, flatter deposit with no splatter. Electrode should be held almost perpendicular and use a rapid stringer or weaving technique with a backwhip at the crater. Bevel pieces 75° on sections 1/8" (3.2mm) or thicker.

Couldn't load pickup availability

Catalog page#: 13-16

Frequently Bought Together

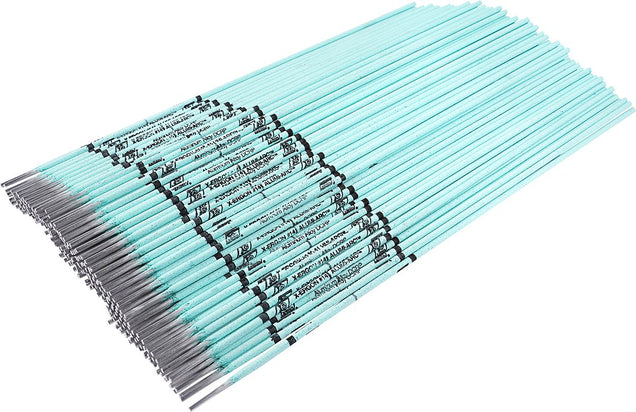

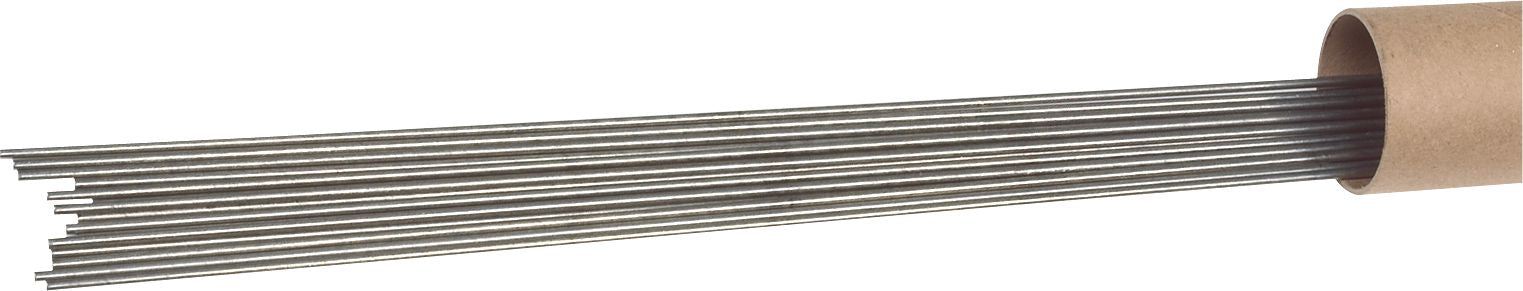

510 Aluminum TIG Wire 1/16"

Couldn't load pickup availability

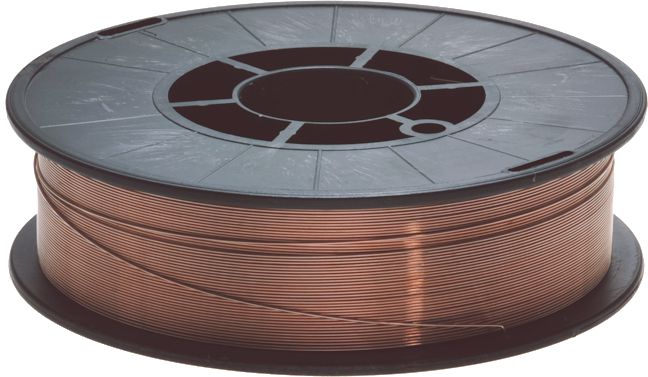

510 Aluminum MIG Welding Wire 3/64"

Couldn't load pickup availability

556 Aluminum TIG Wire 1/16"

Couldn't load pickup availability

Flat Washer Grade 12 Thru-Hardened Steel M10

Couldn't load pickup availability

Autobahn Ergo Magna EZ Crimper Ratcheting Terminal Crimper

Couldn't load pickup availability

Vision Pro Super

Couldn't load pickup availability

106 Mild Steel All Purpose Electrode

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

Carbon Air Arc Stick Rod Electrode 1/4"

Couldn't load pickup availability

211 Cast Iron TIG Wire 1/8"

Couldn't load pickup availability

1100 Gouging and Cutting Stick Rod Electrode 3/16"

Couldn't load pickup availability

109 High Strength Electrode 1/8

Couldn't load pickup availability

Product Description

Highly versatile alloys for all weldable types of aluminum including sheet, forgings, extrusions and castings.Superior Advantages

• Stable, quiet arc with no undercutting

• Good corrosion resistance

Tensile Strength: 35,000 PSIPolarity: DC Reverse

Usage ProcedureMaintain the shortest arc possible, using DC reverse polarity only. On large heavy sections, preheating to 400°F (204°C) will produce faster, flatter deposit with no splatter. Electrode should be held almost perpendicular and use a rapid stringer or weaving technique with a backwhip at the crater. Bevel pieces 75° on sections 1/8" (3.2mm) or thicker.

Technical Specifications

| Item#: | CW1826 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 3/32 " |

| Tensile Strength | 35,000 PSI |

| Base Metal | Aluminum |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 2.0 lb |