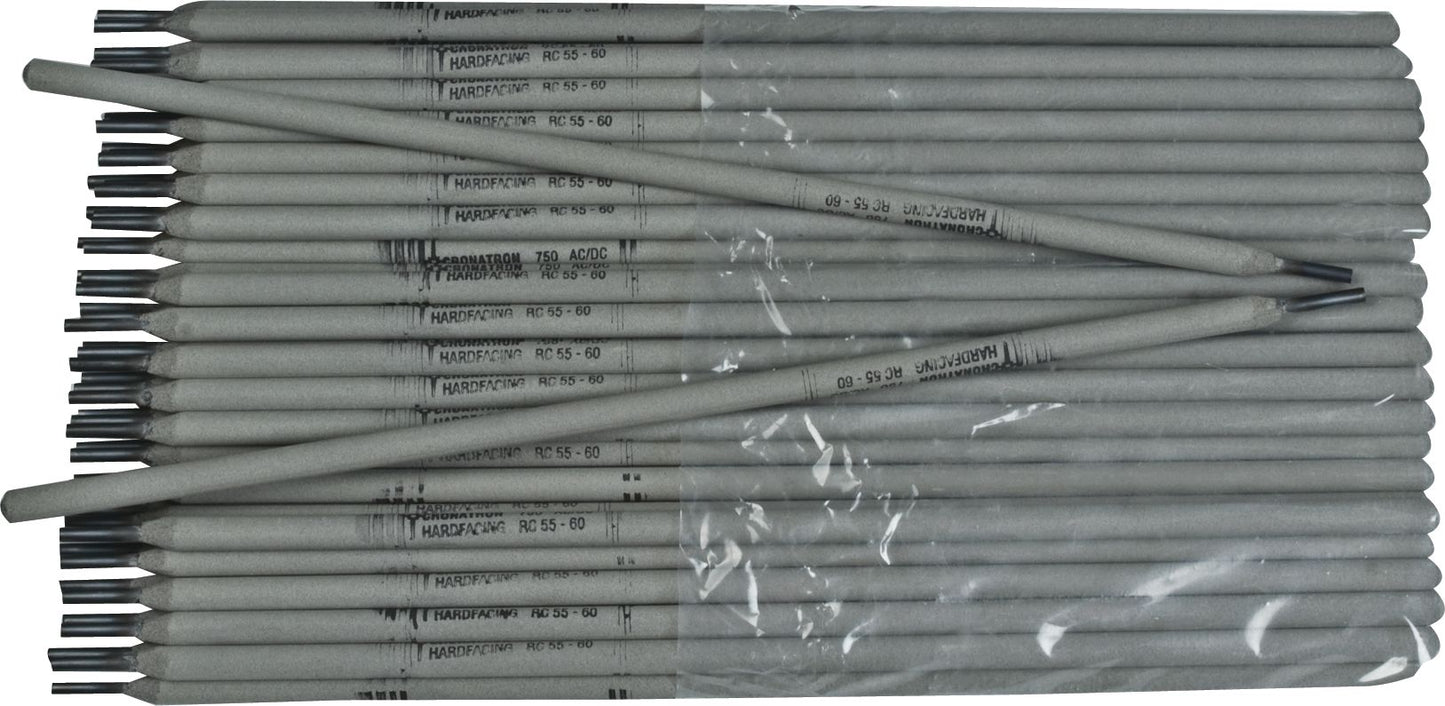

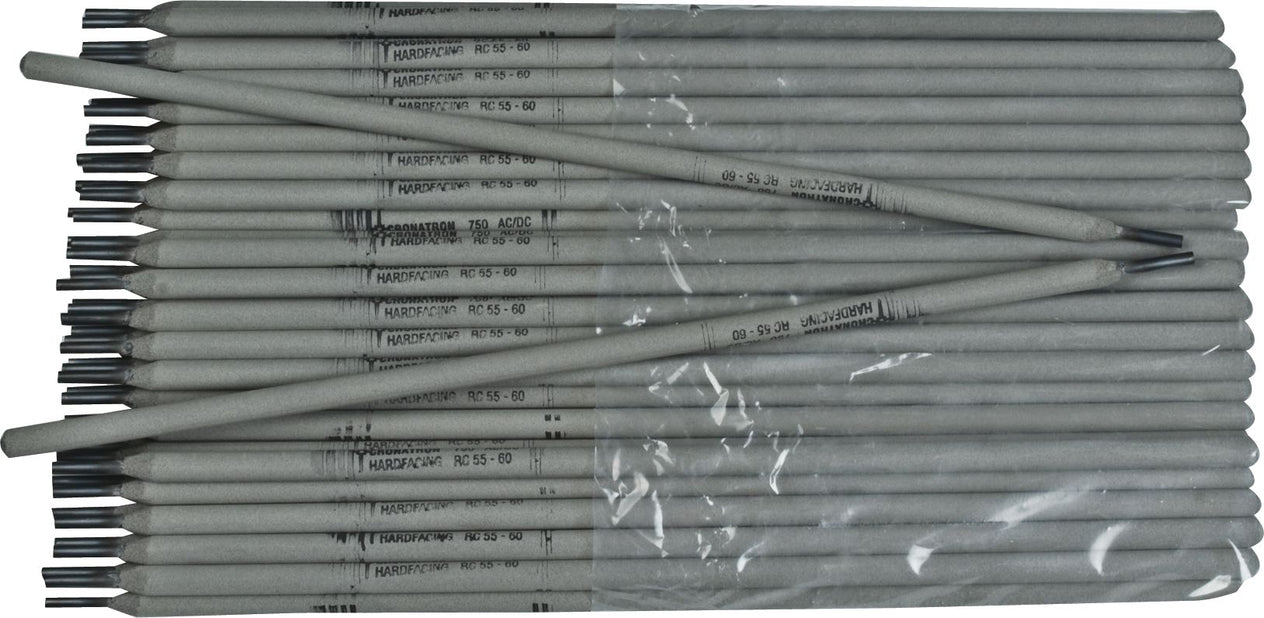

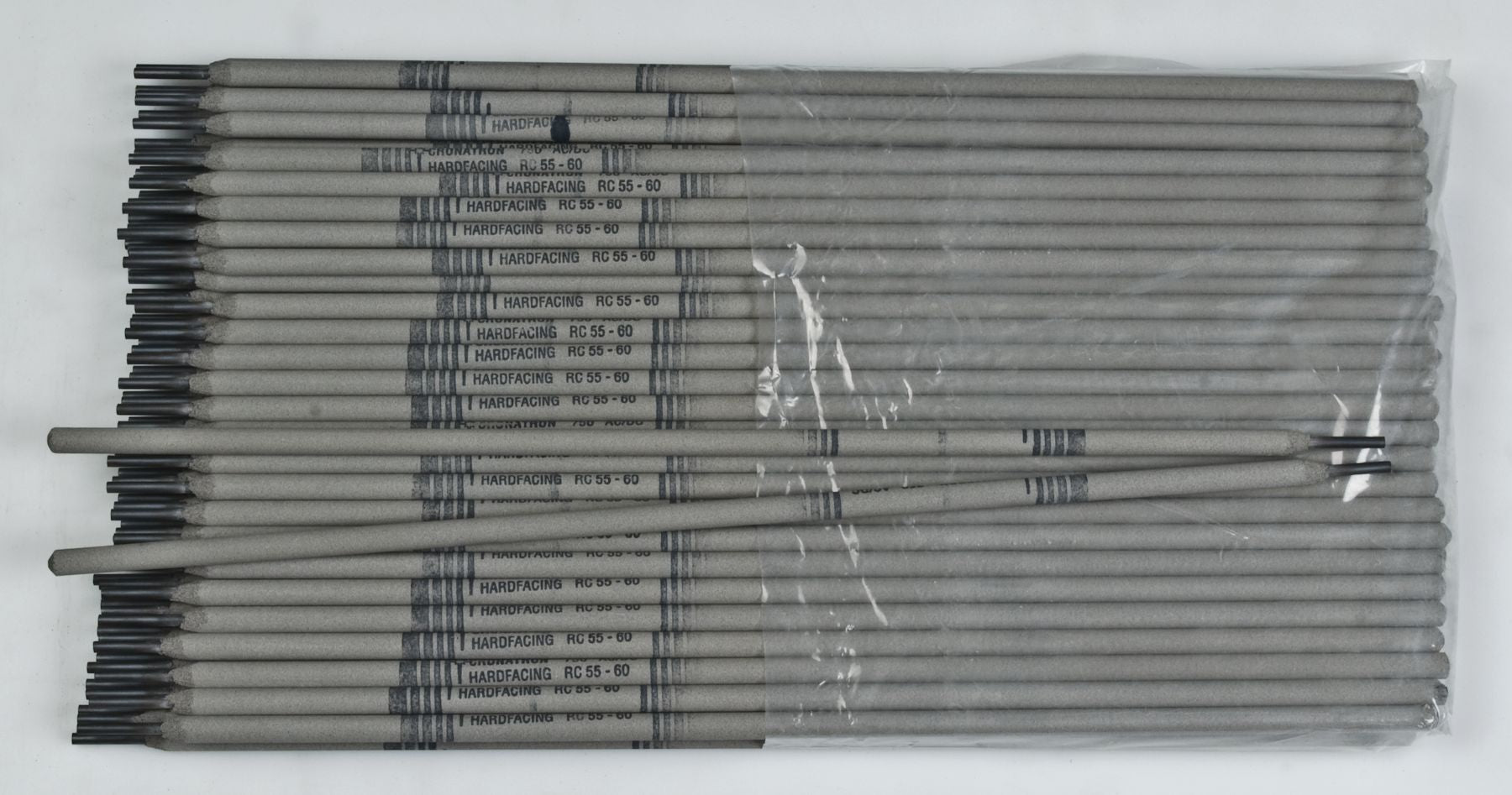

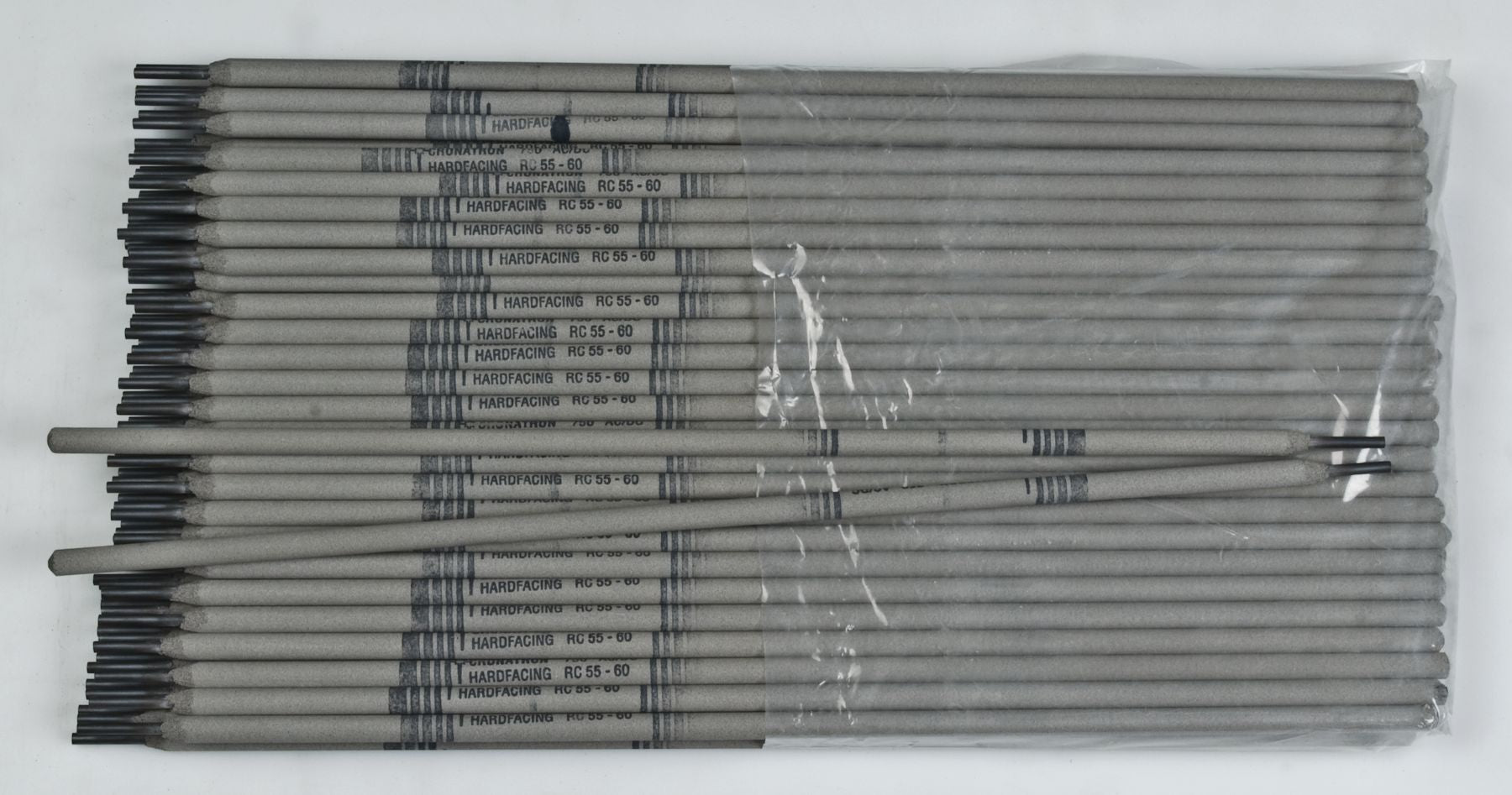

750 Martensitic Hard Facing Stick Rod Electrode, 55 to 60 HRC Hardness, 110 to 160 Amps, AC/DCRP Polarity, 5/32"

(Pack of

10)

SKU:CW1515 Item#: CW1515

Designed for moderate abrasion resistance and impact situations.

Superior Advantages

• Good for metal-to-metal wear

• Torch cuttable

• Heat-treatable

• Unlimited pass-over-pass applications

• Provides good impact resistance

All-position alloy for carbon and alloy steels

Hardness: Rc 55-60Polarity: AC or DC Reverse

Typical Applications

• Dredger and shovel teeth

• Hammers

• Conveyor screws

• Shredders

• Shear blades

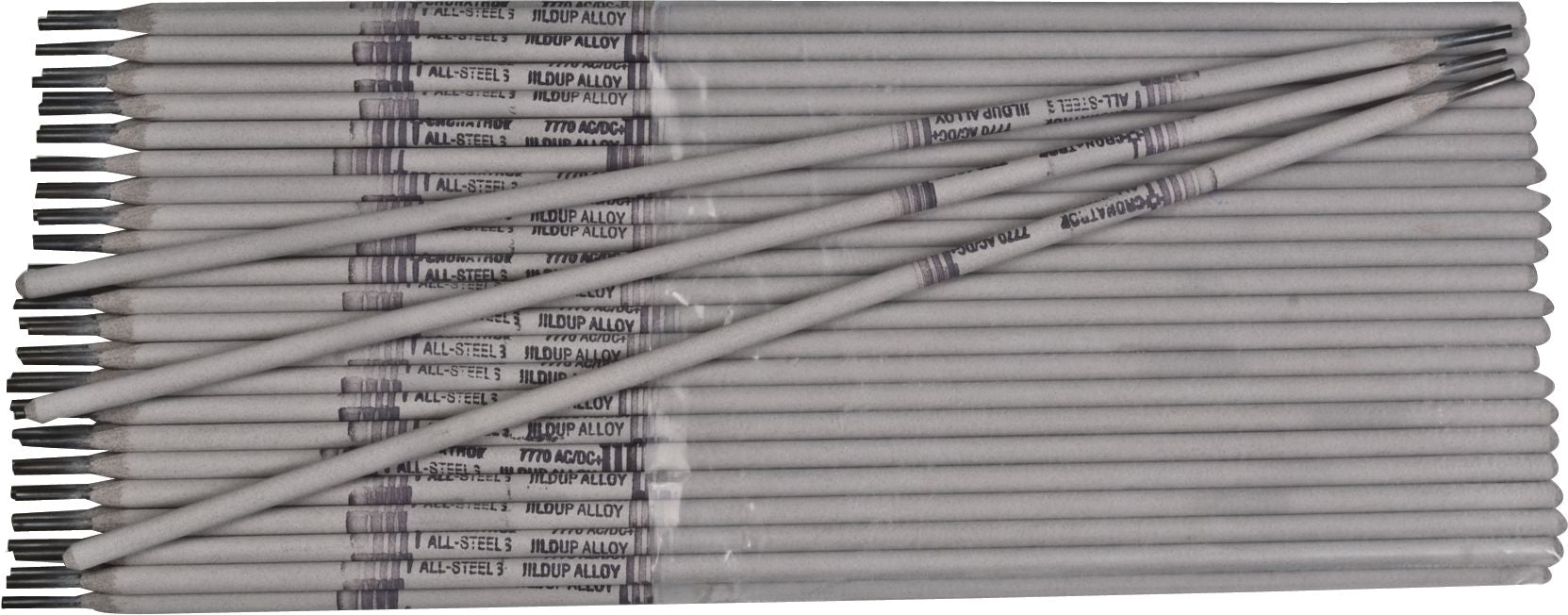

Technical TipFor austenitic manganese steel, use a buffer layer of CRONAWEAR™ 7770, followed by multiple passes of CRONAWEAR 750 (to achieve full hardness). Keep the arc close. For vertical welds, use rapid weave and hesitate over each crater before extinguishing arc.

Frequently Bought Together

176 Extreme Abrasion With Impact 1/4X18IN

Couldn't load pickup availability

750 Martensitic Hard Facing Stick Electrode 1/8"

Couldn't load pickup availability

7770 Hard Facing Buildup Stick Rod Electrode 1/8"

Couldn't load pickup availability

750 Martensitic Hard Facing Stick Electrode 1/8"

Couldn't load pickup availability

H3 Martensitic Hard Facing MIG Welding Wire 0.045"

Couldn't load pickup availability

7500 Martensitic MIG Welding Wire 0.045"

Couldn't load pickup availability

Nylon Cable Tie 8" Black

Couldn't load pickup availability

Nylon Cable Tie 15.25" Black

Couldn't load pickup availability

Nylon Cable Tie 11.75" Black

Couldn't load pickup availability

331 Mild and Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

Flat Soapstone 1/2"

Couldn't load pickup availability

Rosin Core Solder 0.032"

Couldn't load pickup availability

Product Description

Designed for moderate abrasion resistance and impact situations.Superior Advantages

• Good for metal-to-metal wear

• Torch cuttable

• Heat-treatable

• Unlimited pass-over-pass applications

• Provides good impact resistance

All-position alloy for carbon and alloy steels

Hardness: Rc 55-60Polarity: AC or DC Reverse

Typical Applications

• Dredger and shovel teeth

• Hammers

• Conveyor screws

• Shredders

• Shear blades

Technical TipFor austenitic manganese steel, use a buffer layer of CRONAWEAR™ 7770, followed by multiple passes of CRONAWEAR 750 (to achieve full hardness). Keep the arc close. For vertical welds, use rapid weave and hesitate over each crater before extinguishing arc.

Technical Specifications

| Item#: | CW1515 |

|---|---|

| Welding Process | Stick |

| Type | Stick Electrode |

| Diameter | 5/32 " |

| Base Metal | Martensitic |

| Hardness | 55-60 HRC |

| Polarity | AC/DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 10.5 lb |

Product Restrictions