676 Flux Corred Wire Optional Sheilding Gas 100% Co2 Up 64Rc In Hardness For Carbon And Low Alloy And Manganese Steels

(Pack of

33)

SKU:EG67680045 Item#: EG67680045

A specially formulated flux cored wire designed to produce extremely wear-resistant deposits. The high concentration of small primary carbides greatly improves toughness and abrasion resistance over conventional chromium carbide alloys. Can be applied to carbon, low alloy, and manganese steels and can be used in hot wear applications up to 900°F/482°C.

• Smooth arc for superior control

• No gas required

• Deposit cross-checks readily

• Resists hot wear up to 900°F/482°C

• Hardness: Up to 64Rc

• Max Number of Passes: 2

• Impact Resistance: Moderate

• Machinability: Grind only

• Magnetic: – On Carbon Steel: Slightly – On Manganese Steel: No

• Hot Wear Applications: Up to 900°F/482°C

• Current: DCEP (DC+)

• Shielding Gas: Optional, 100% CO2

Frequently Bought Together

7500 Martensitic MIG Welding Wire 0.045"

Couldn't load pickup availability

706 Hard Facing Buildup Stick Rod Electrode 3/32"

Couldn't load pickup availability

706 Hard Facing Buildup Stick Rod Electrode 1/8"

Couldn't load pickup availability

711 Carbide Hard Facing Stick Rod Electrode 3/16"

Couldn't load pickup availability

7350 Carbide Hard Facing Stick Rod Electrode 1/2"

Couldn't load pickup availability

7230 Carbide Hard Facing Stick Rod Electrode 3/8"

Couldn't load pickup availability

SAE J995C Locknut with Nylon Insert Grade 8 3/8-16

Couldn't load pickup availability

IFI 100/107 Top Locknut Grade C 5/8-11

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 1/4"

Couldn't load pickup availability

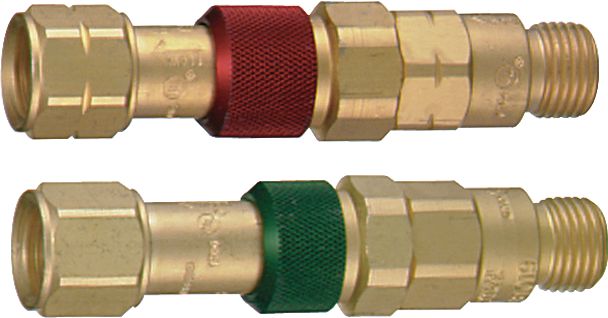

Oxy Acetylene Fuel and Oxygen Quick Connector

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

45 Silver Bare Brazing Rod 1/8"

Couldn't load pickup availability

Product Description

A specially formulated flux cored wire designed to produce extremely wear-resistant deposits. The high concentration of small primary carbides greatly improves toughness and abrasion resistance over conventional chromium carbide alloys. Can be applied to carbon, low alloy, and manganese steels and can be used in hot wear applications up to 900°F/482°C.• Smooth arc for superior control

• No gas required

• Deposit cross-checks readily

• Resists hot wear up to 900°F/482°C

• Hardness: Up to 64Rc

• Max Number of Passes: 2

• Impact Resistance: Moderate

• Machinability: Grind only

• Magnetic: – On Carbon Steel: Slightly – On Manganese Steel: No

• Hot Wear Applications: Up to 900°F/482°C

• Current: DCEP (DC+)

• Shielding Gas: Optional, 100% CO2

Technical Specifications

| Item#: | EG67680045 |

|---|---|

| Welding Process | Flux-Core Arc Welding |

| Type | Flux-Cored Wire |

| Diameter | .045 " |

| Base Metal | Carbon And Alloy Steels |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 37.49 lb |

Product Restrictions