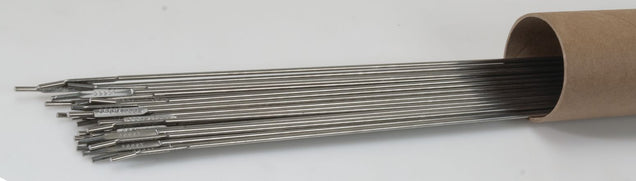

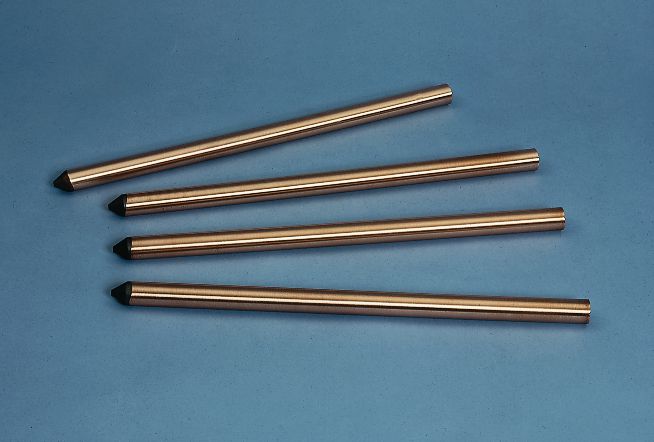

3000 Nickel Stick Rod Electrode, Flux Coated, 50 to 70 Amps, 33% Elongation, DCRP Polarity, Extremely Corrosion-Resistant, 3/32"

(Pack of

5)

SKU:CW1992 Item#: CW1992

Compatible with Inconel, other nickel-based alloys, Monel® and dissimilar alloys.

Superior Advantages

• Extremely corrosion-resistant

• High temperature usage – up to 2,000°F (1,093°C)

• Low temperature usage – down to –320°F (–196°C)

• Maximum versatility

• Dissimilar metals joining

Withstands operating temperatures from –320°F to +2,000°F (–196°C to +1,093°C).

Tensile Strength: 100,000 PSIElongation: 33%Polarity: DC Reverse

Typical Applications

• Furnaces and boilers

• Heat treat baskets

• Power plants

• Chemical processing

Usage ProcedureUse DC reverse polarity with normal maintenance welding procedures. Surface should be as clean as possible. Hold a short arc and tilt electrode 10° in the direction of travel. Remove slag between passes. Preheating the weld metal is not necessary unless the base metal and/or thickness require it. Do not weave more than twice the diameter of the core wire.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

Catalog page#: 13-25

Frequently Bought Together

Flat Washer Grade 12 Thru-Hardened Steel M10

Couldn't load pickup availability

Autobahn Ergo Magna EZ Crimper Ratcheting Terminal Crimper

Couldn't load pickup availability

Vision Pro Super

Couldn't load pickup availability

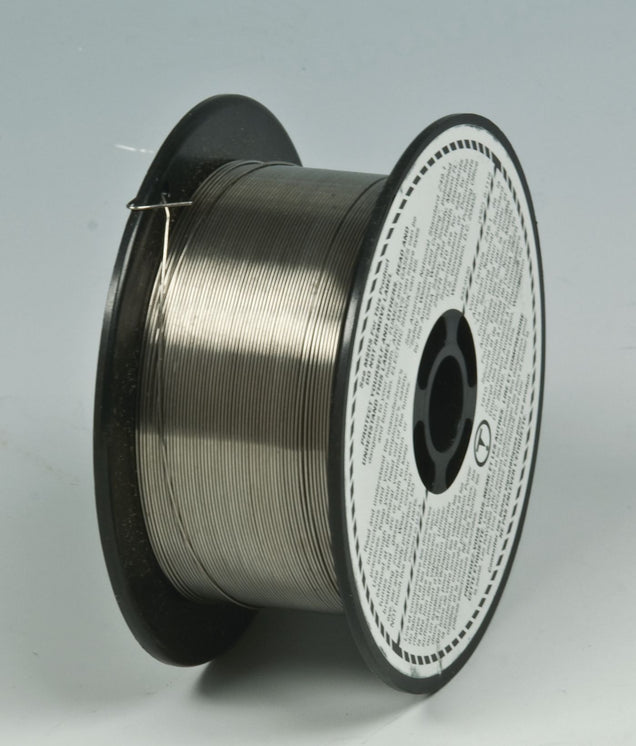

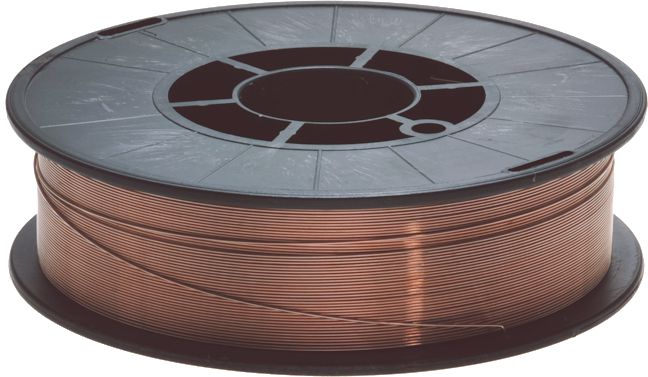

ER309L Stainless Steel MIG Welding Wire 0.045"

Couldn't load pickup availability

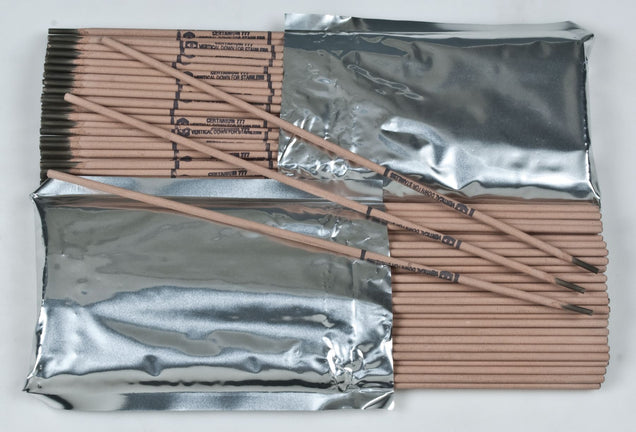

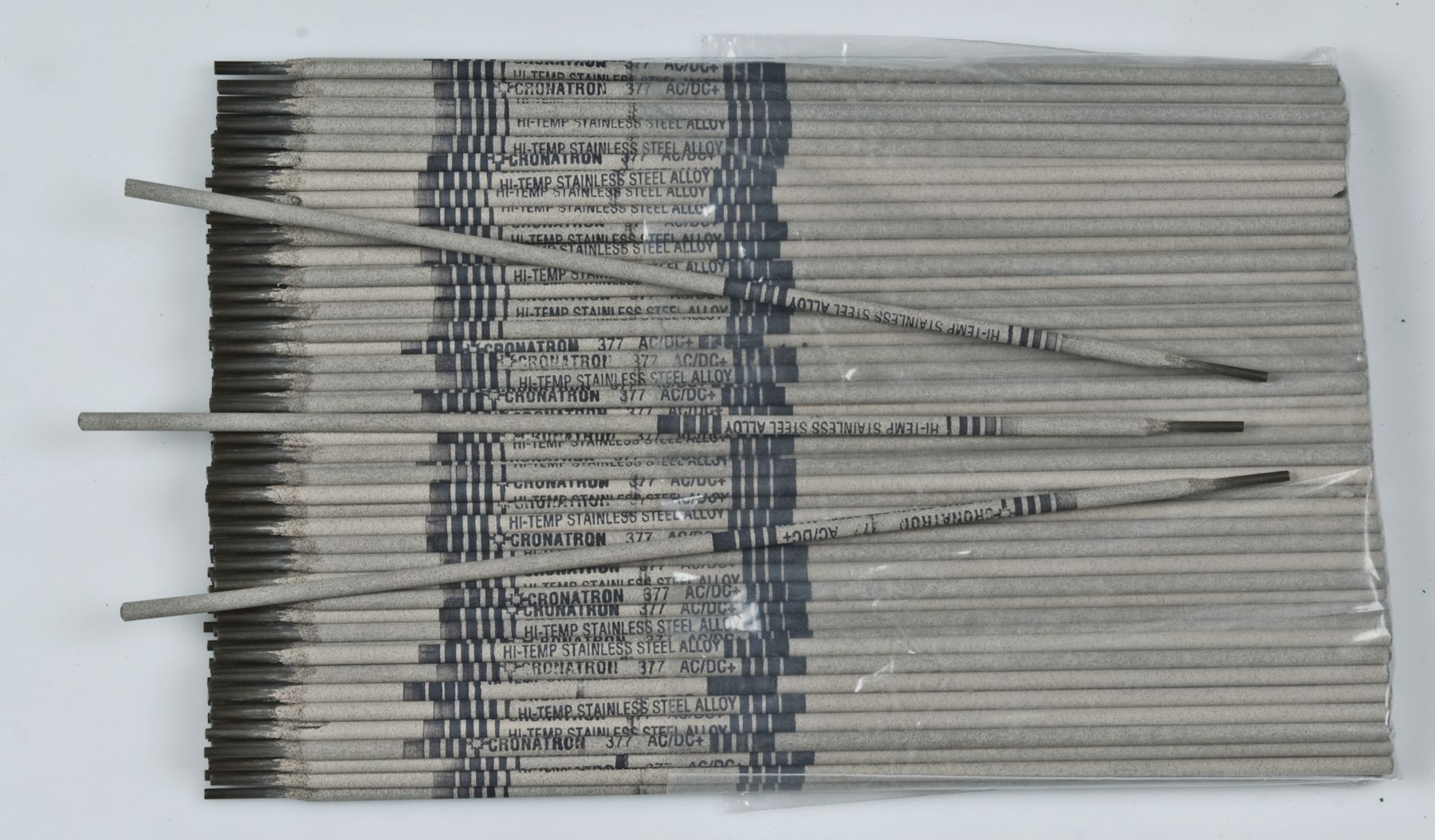

377 Stainless Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

383 Stainless Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

106 Mild Steel All Purpose Electrode

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

Carbon Air Arc Stick Rod Electrode 1/4"

Couldn't load pickup availability

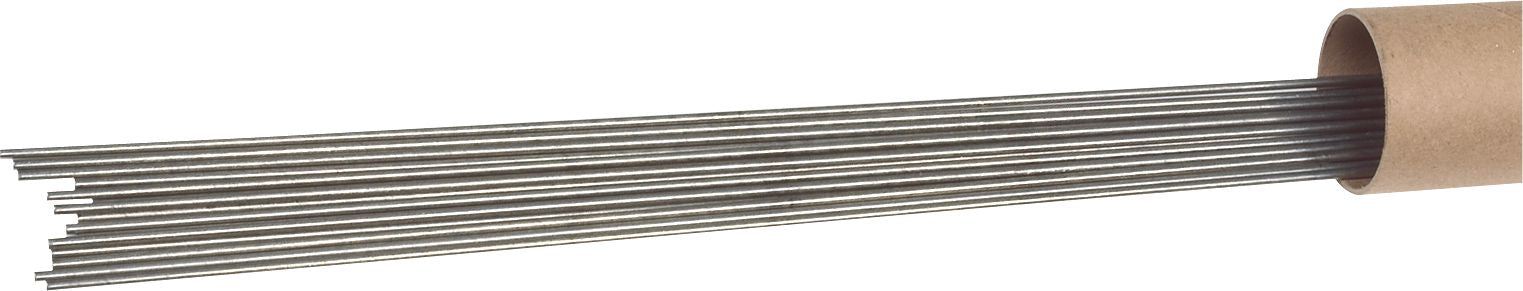

211 Cast Iron TIG Wire 1/8"

Couldn't load pickup availability

1100 Gouging and Cutting Stick Rod Electrode 3/16"

Couldn't load pickup availability

109 High Strength Electrode 1/8

Couldn't load pickup availability

Product Description

Compatible with Inconel, other nickel-based alloys, Monel® and dissimilar alloys.Superior Advantages

• Extremely corrosion-resistant

• High temperature usage – up to 2,000°F (1,093°C)

• Low temperature usage – down to –320°F (–196°C)

• Maximum versatility

• Dissimilar metals joining

Withstands operating temperatures from –320°F to +2,000°F (–196°C to +1,093°C).

Tensile Strength: 100,000 PSIElongation: 33%Polarity: DC Reverse

Typical Applications

• Furnaces and boilers

• Heat treat baskets

• Power plants

• Chemical processing

Usage ProcedureUse DC reverse polarity with normal maintenance welding procedures. Surface should be as clean as possible. Hold a short arc and tilt electrode 10° in the direction of travel. Remove slag between passes. Preheating the weld metal is not necessary unless the base metal and/or thickness require it. Do not weave more than twice the diameter of the core wire.

Technical Specifications

| Item#: | CW1992 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 3/32 " |

| Tensile Strength | 100,000 PSI |

| Elongation | 33 % |

| Base Metal | Nickel |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.0 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov