889 Cast Iron Stick Rod Electrode, Flux Coated, 180 to 222 HB Hardness, 60 to 100 Amps, DCRP/DCSP/AC Polarity, 5/32"

(Pack of

10)

SKU:P12006 Item#: P12006

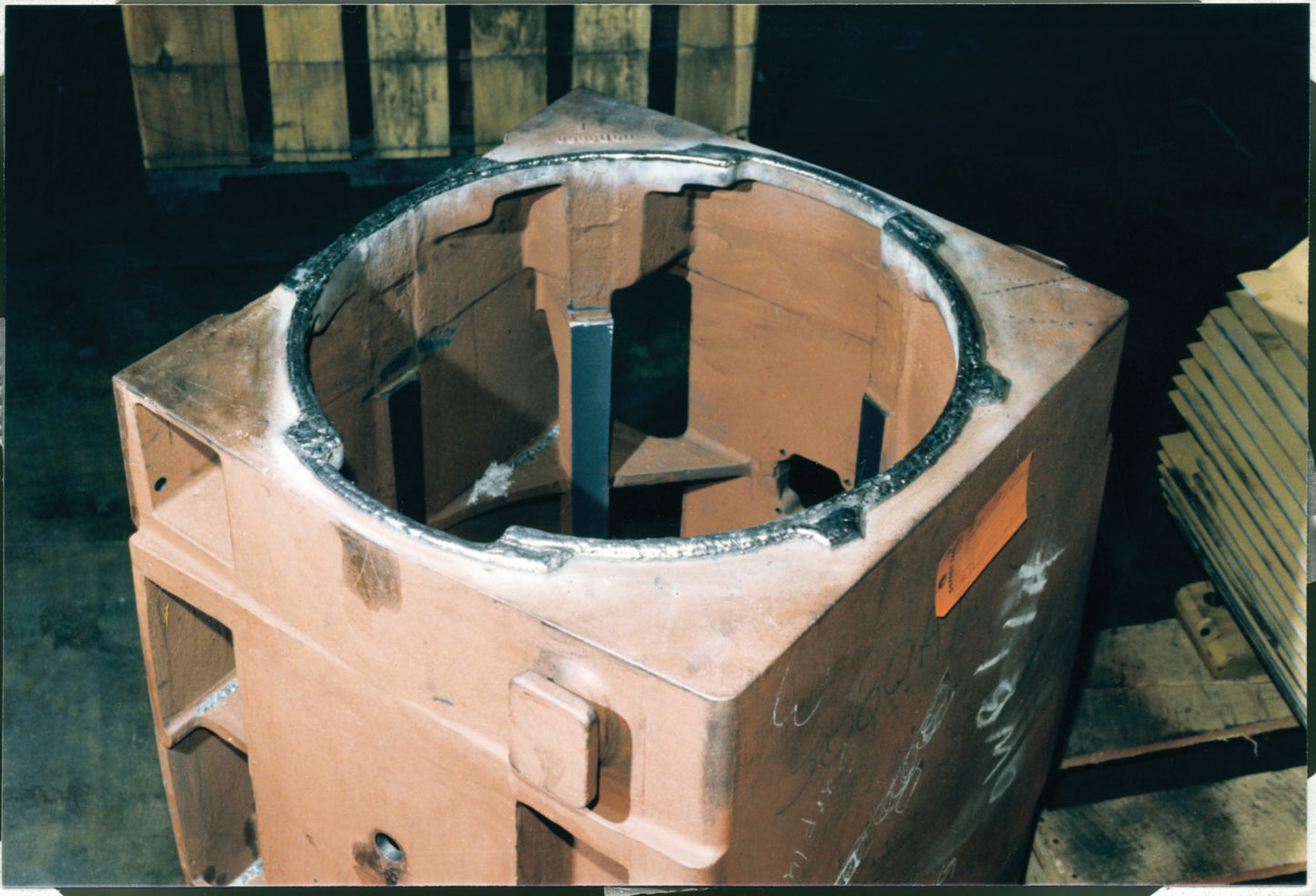

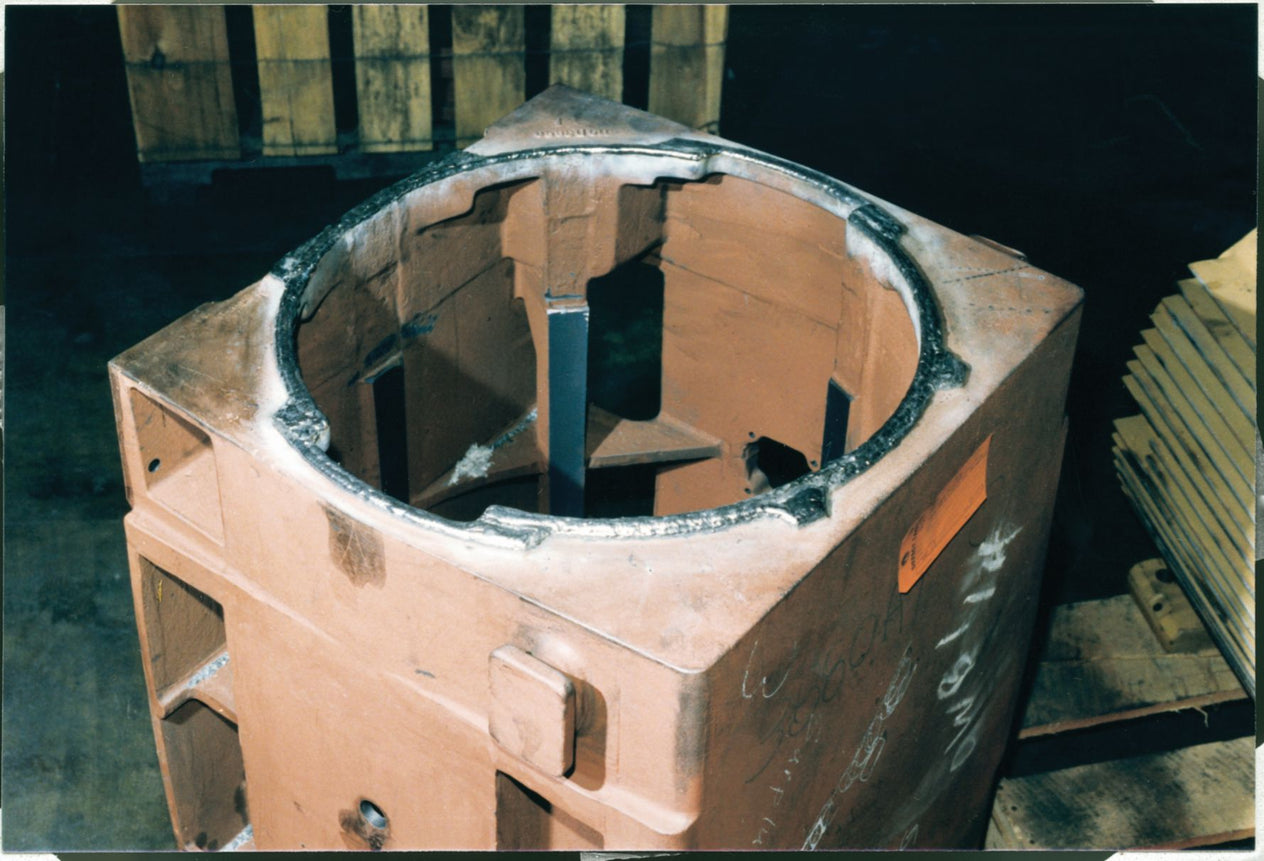

All-position welding for any type of weldable cast iron repair and cast iron to steel.

Superior Advantages

• High strength welds

• Fully machinable

• Pass-over-pass welding to save time

• All-position welding may eliminate the need to dismantle equipment to perform repairs

For all cast irons – even steel to cast iron

Tensile Strength: Up to 84,000 PSIHardness: 180 – 222 BHNPolarity: AC or DC Straight or Reverse

Typical Applications

• Pump and bearing housings

• Cylinder blocks and heads

• Machine bases

• Manifolds and exhaust systems

Usage Procedure:Remove grease, scale and other impurities from weld area. Bevel cracks or breaks (70° to 90° “V”). CRONACUT™ 1100 is the fastest and easiest method to prepare section for weld repairing. Use a short to medium arc at the lowest possible amperage for best results. Employ weaving technique or stringer beads. Peen to relieve stress. Remove slag between passes. Slow cooling to room temperature recommended.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov

Frequently Bought Together

130 Hpm Cast Iron Machinable Electrode 1/8

Couldn't load pickup availability

211 Cast Iron Stick Rod Electrode 5/32"

Couldn't load pickup availability

889 Cast Iron Stick Rod Electrode 1/8"

Couldn't load pickup availability

Extendable Handle Ratchet 3/8 Drive

Couldn't load pickup availability

12" Auto-Adjust Pliers

Couldn't load pickup availability

M12™ FUEL™ HACKZALL® Reciprocating Saw Kit

Couldn't load pickup availability

IFI 100/107 Top Locknut Grade C 5/8-11

Couldn't load pickup availability

SAE J995C Locknut with Nylon Insert Grade 8 3/8-16

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 1/4"

Couldn't load pickup availability

Rosin Core Solder 1/16"

Couldn't load pickup availability

Rosin Core Solder 1/16"

Couldn't load pickup availability

Round Soapstone 1/4 x 5"

Couldn't load pickup availability

345 Tool Steel TIG Wire 3/32"

Couldn't load pickup availability

510 Aluminum TIG Wire 1/16"

Couldn't load pickup availability

510 Aluminum MIG Welding Wire 3/64"

Couldn't load pickup availability

Product Description

All-position welding for any type of weldable cast iron repair and cast iron to steel.Superior Advantages

• High strength welds

• Fully machinable

• Pass-over-pass welding to save time

• All-position welding may eliminate the need to dismantle equipment to perform repairs

For all cast irons – even steel to cast iron

Tensile Strength: Up to 84,000 PSIHardness: 180 – 222 BHNPolarity: AC or DC Straight or Reverse

Typical Applications

• Pump and bearing housings

• Cylinder blocks and heads

• Machine bases

• Manifolds and exhaust systems

Usage Procedure:Remove grease, scale and other impurities from weld area. Bevel cracks or breaks (70° to 90° “V”). CRONACUT™ 1100 is the fastest and easiest method to prepare section for weld repairing. Use a short to medium arc at the lowest possible amperage for best results. Employ weaving technique or stringer beads. Peen to relieve stress. Remove slag between passes. Slow cooling to room temperature recommended.

Technical Specifications

| Item#: | P12006 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 5/32 " |

| Tensile Strength | 84,000 PSI |

| Base Metal | Cast Iron |

| Hardness | 180-222 BHN |

| Polarity | DCRP/AC |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 10.0 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov