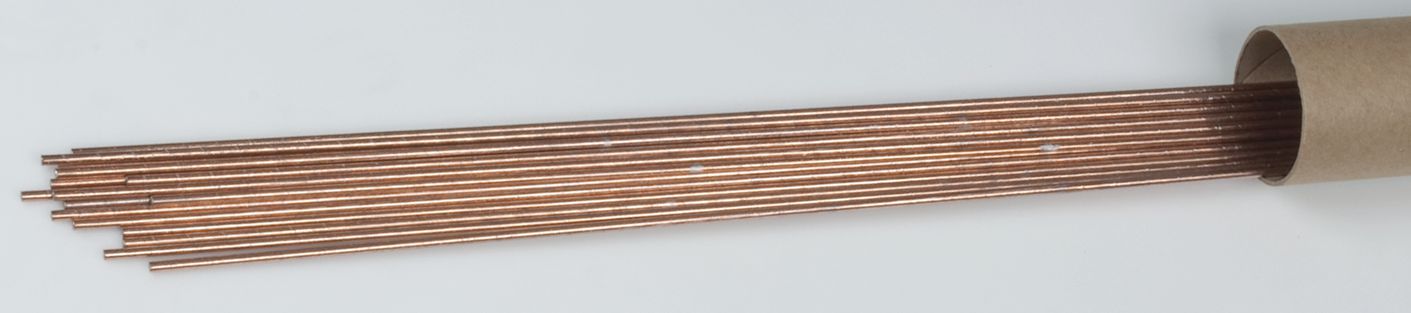

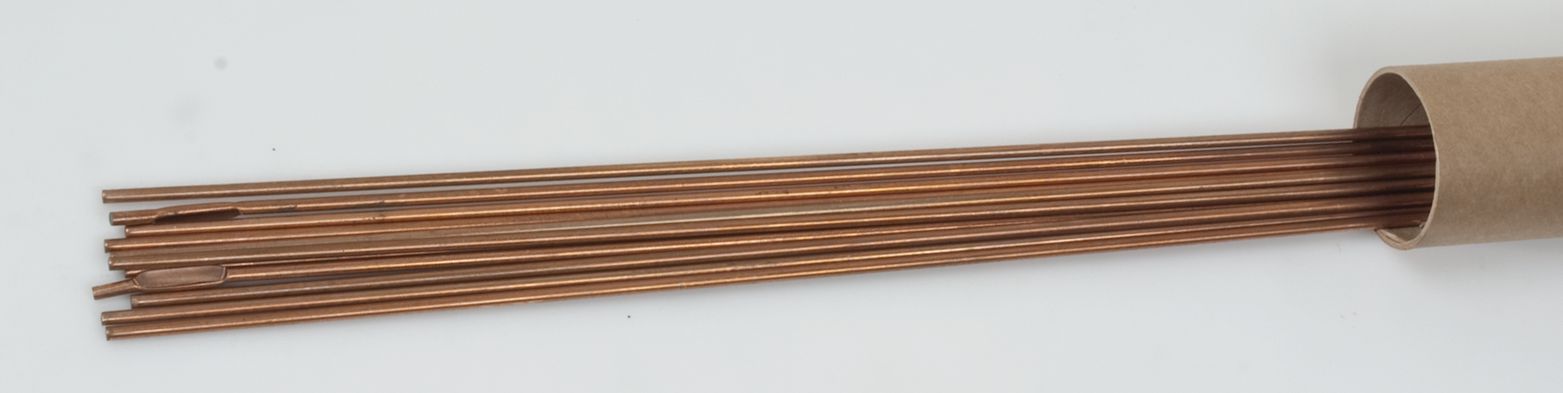

345 Tool Steel TIG Wire, Solid, 54 to 58 HRC Hardness, 100% Ar Shielding Gas, DCSP Polarity, 36" Length, 3/32"

(Pack of

2)

SKU:CW1889 Item#: CW1889

A broad selection of premium alloys to use for nearly any tool steel application and repair.

Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 54-58

Polarity: DC Straight

Gas: 100% Ar

Universal and “H” Series, Chromium Hot Work Tool SteelThe principal elements in this alloy are chromium, tungsten, moly and vanadium. This chemistry provides an extremely tough deposit with deep air-hardening capabilities up to 12". Types: H11, 12, 13, S1, S7, 01, 06.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov

Catalog page#: 13-24

Frequently Bought Together

SAE Flat Washer Thru-Hardened Steel 3/8"

Couldn't load pickup availability

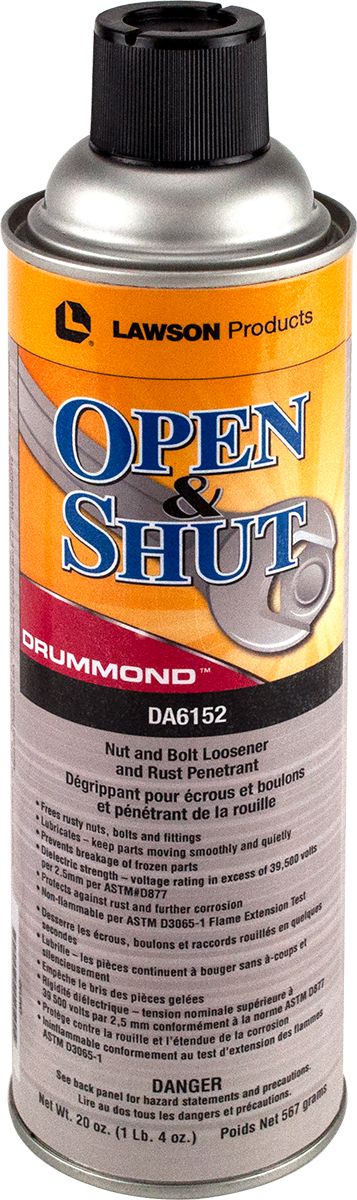

Lawson Open & Shut Nut & Bolt Loosener, Rust Penetrant, SKU DA6152, 20 oz Aerosol Can

Couldn't load pickup availability

SAE J995C Locknut with Nylon Insert Grade 8 1/4-20

Couldn't load pickup availability

349 Tool Steel TIG Wire 1/8"

Couldn't load pickup availability

345 Tool Steel TIG Wire 5/32"

Couldn't load pickup availability

349 Tool Steel TIG Wire 3/32"

Couldn't load pickup availability

24A-62 MIG Welding Nozzle 5/8"

Couldn't load pickup availability

Round Soapstone 1/4 x 5"

Couldn't load pickup availability

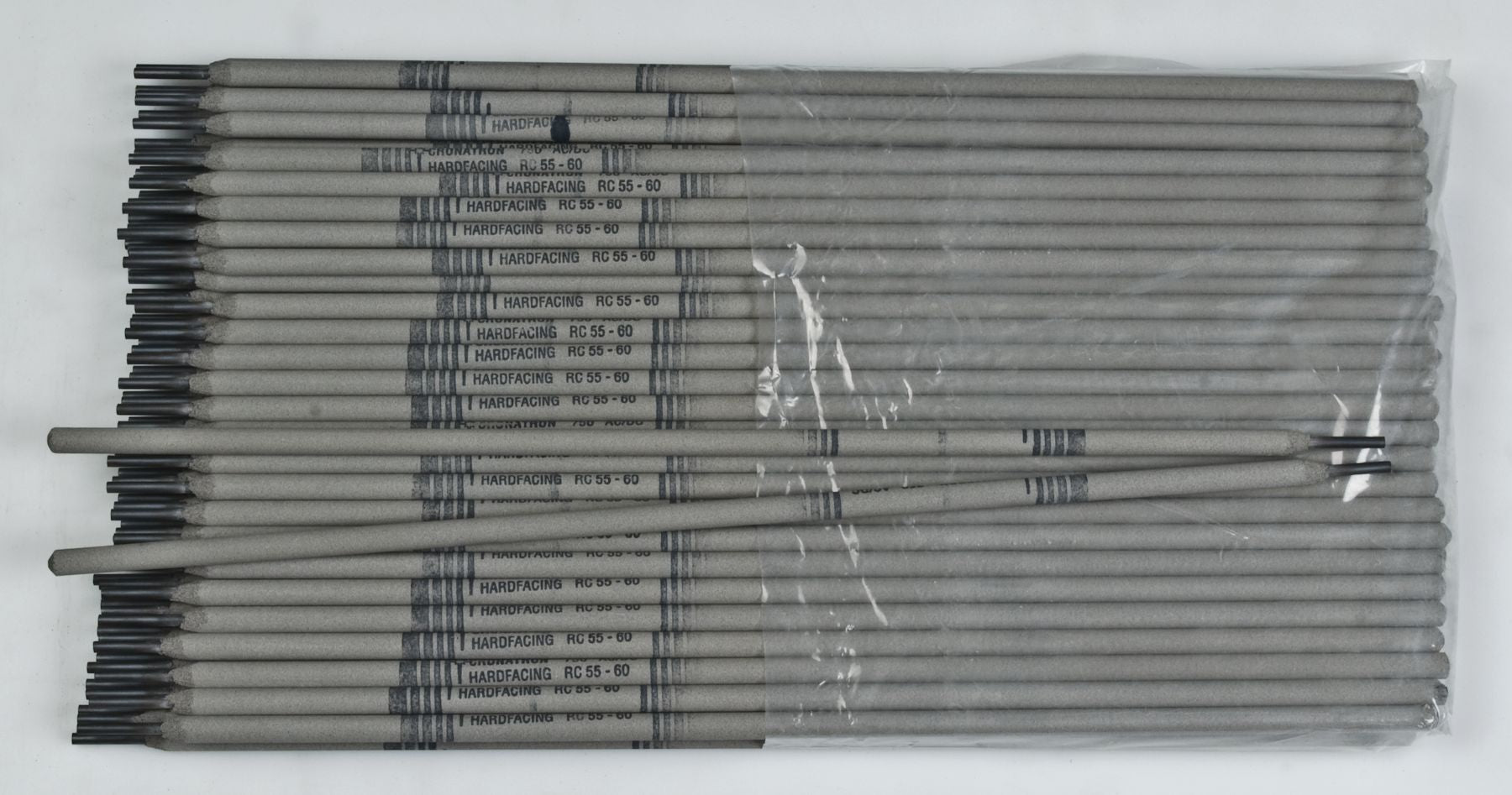

750 Martensitic Hard Facing Stick Electrode 1/8"

Couldn't load pickup availability

106 Mild Steel All Purpose Electrode

Couldn't load pickup availability

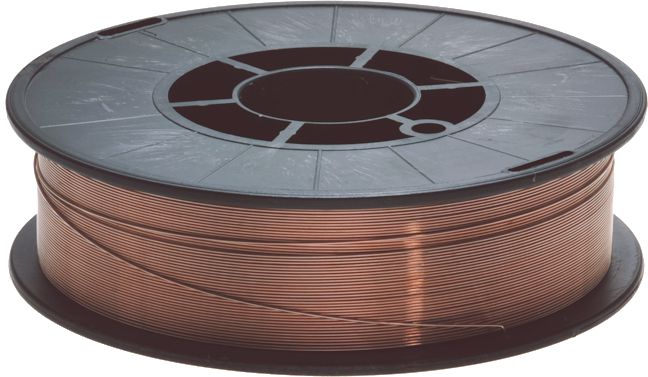

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

333 Dissimilar Steel TIG Wire 3/32"

Couldn't load pickup availability

Product Description

A broad selection of premium alloys to use for nearly any tool steel application and repair.Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 54-58

Polarity: DC Straight

Gas: 100% Ar

Universal and “H” Series, Chromium Hot Work Tool SteelThe principal elements in this alloy are chromium, tungsten, moly and vanadium. This chemistry provides an extremely tough deposit with deep air-hardening capabilities up to 12". Types: H11, 12, 13, S1, S7, 01, 06.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Technical Specifications

| Item#: | CW1889 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | 3/32 " |

| Length | 36 " |

| Base Metal | Tool Steel |

| Hardness | 54-58 HRC |

| Shielding Gas | 100% Ar |

| Polarity | DCSP |

| Quantity Per Package | 2.0000 |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 0.5 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov