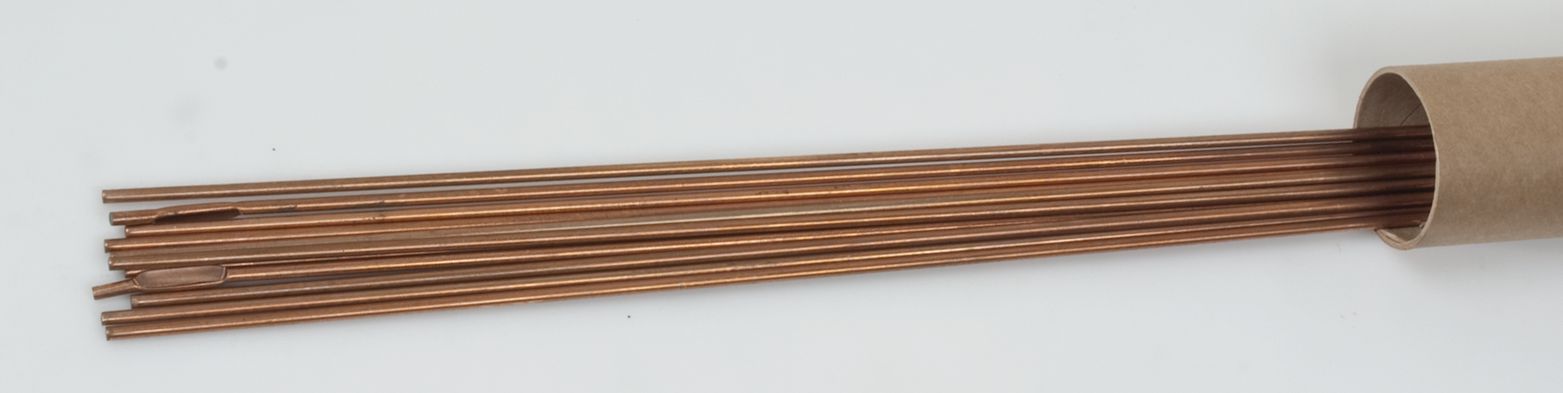

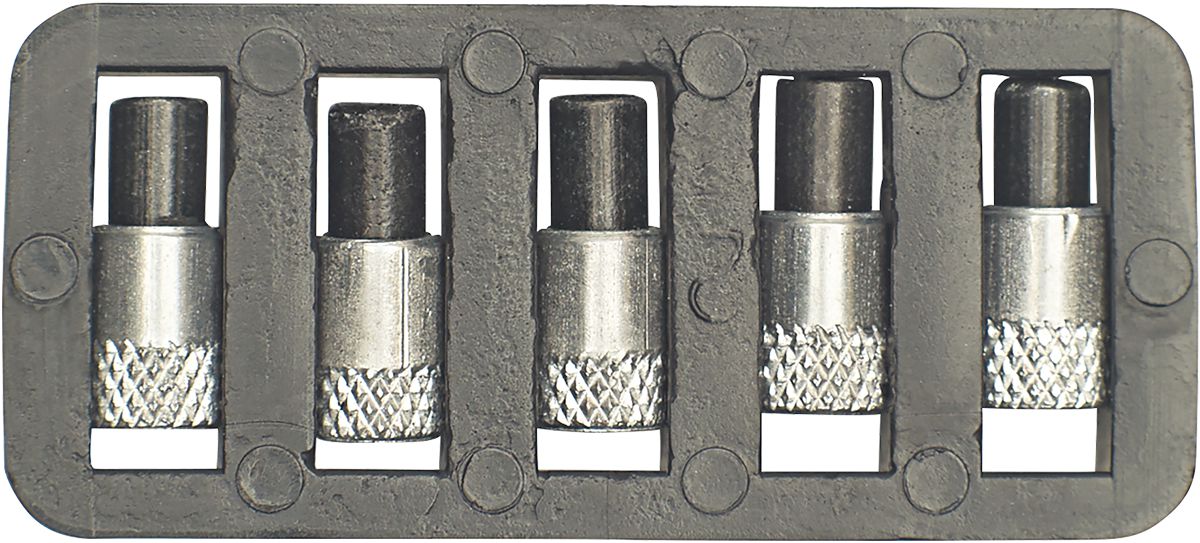

349 Tool Steel TIG Wire, Solid, 33 to 36 HRC Hardness, 100% Ar Shielding Gas, 26% Elongation, 36" Length, 1/16"

(Pack of

2)

SKU:CW1979 Item#: CW1979

Specially formulated for welding P-mold steels and most chrome-moly alloy steels.

Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Tensile Strength: 89,700 PSIYield Strength: 73,400 PSIElongation: 26%Hardness: Rc 33-36Polarity: DC StraightGas: 100% Ar

Typical Applications

• Die-casting dies

• Injection molds

• Compression molding of plastics and chrome-moly steels like AISI 4130, 4140, 8620 and 8640

Usage ProcedureMaintain a short arc with minimal weave. Preheat as prescribed by base metal.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov

Catalog page#: 13-24

Frequently Bought Together

Butt Connector 16 to 14 AWG Clear

Couldn't load pickup availability

Butt Connector 22 to 18 AWG Clear

Couldn't load pickup availability

High Solids Paints Gloss Black

Couldn't load pickup availability

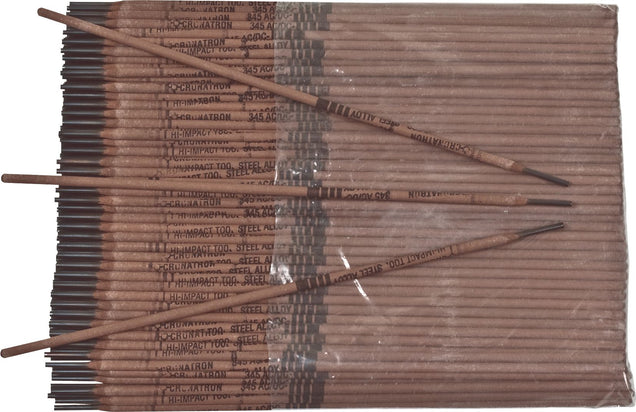

345 Tool Steel TIG Wire 5/32"

Couldn't load pickup availability

349 Tool Steel TIG Wire 3/32"

Couldn't load pickup availability

349 Tool Steel TIG Wire 0.035"

Couldn't load pickup availability

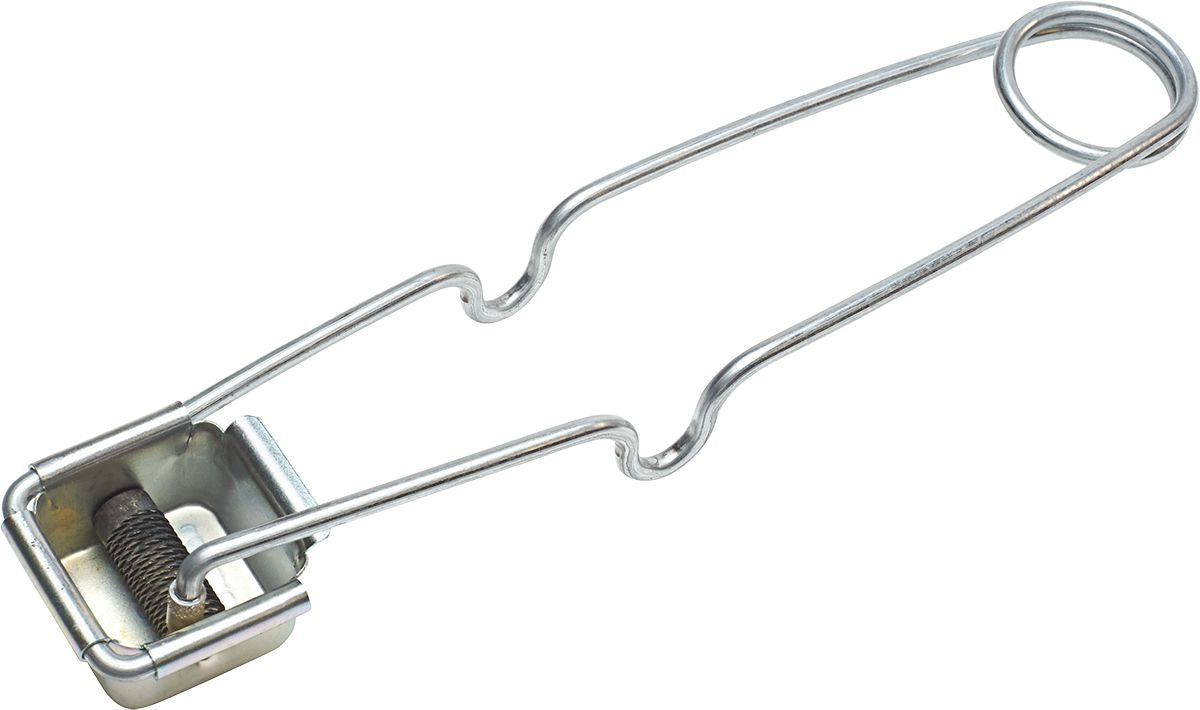

Oxy Acetylene Fuel Gas Single Flint Striker

Couldn't load pickup availability

Oxy Acetylene Fuel Gas Single Replacement Flint

Couldn't load pickup availability

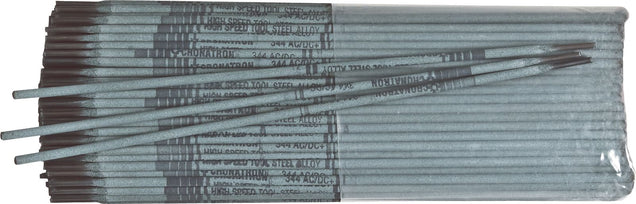

333 Dissimilar Steel TIG Wire 1/16"

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

331 Mild and Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

Product Description

Specially formulated for welding P-mold steels and most chrome-moly alloy steels.Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Tensile Strength: 89,700 PSIYield Strength: 73,400 PSIElongation: 26%Hardness: Rc 33-36Polarity: DC StraightGas: 100% Ar

Typical Applications

• Die-casting dies

• Injection molds

• Compression molding of plastics and chrome-moly steels like AISI 4130, 4140, 8620 and 8640

Usage ProcedureMaintain a short arc with minimal weave. Preheat as prescribed by base metal.

Technical Specifications

| Item#: | CW1979 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | 1/16 " |

| Length | 36 " |

| Tensile Strength | 89,700 PSI |

| Yield Strength | 73,400 PSI |

| Elongation | 26 % |

| Base Metal | Tool Steel |

| Hardness | 33-36 HRC |

| Shielding Gas | 100% Ar |

| Polarity | DCSP |

| Quantity Per Package | 2.0000 |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 2.5 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov