Hi-Load Masonry Anchor Steel M10 x 100mm

(Pack of

2)

• 8.8 metric grade steel with yellow dichromate zinc plating

• Exceptional strength coupled with the ability to resist vibratory loads

• Designed to equally distribute force to all sides

• Center plastic ring prevents anchor from spinning during installation

• Stud version can be adjusted for standoff height (shimming and leveling)

• Hex bolt version for applications where a finished appearance is required

• Removable; no cutting required

• Collapsible sleeve allows for secure clamping force

• Heavy-duty expansion sleeve provides follow-up expansion for fastening in tension zones of concrete such as under bridge decks, floor slabs and beams

• Designed for seismic (subject to or caused by an earthquake, vibration, strong impact or earth shaking) and dynamic (constant applied load) applications

• Applications include heavy machinery, conveyors, safety railings, dock bumpers and connecting structural components

Installation Procedure

1. Drill hole to correct diameter and depth.

2. Remove dust and rubble from hole with compressed air and a brush.

3. Using a hammer, tap the anchor through the material to be fastened until the anchor is firmly seated.

4. Tighten the anchor to the specified torque.

*Maximum values shown; use one-fourth of the ultimate tensile and shear capacities for the recommended 4:1 safety factor.

Frequently Bought Together

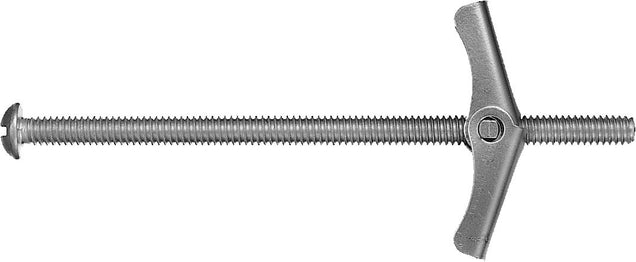

Wing-Type Toggle Bolt Anchor Steel #10-24 x 3"

Couldn't load pickup availability

Conical Screw Anchor Kit Plastic 301Pcs

Couldn't load pickup availability

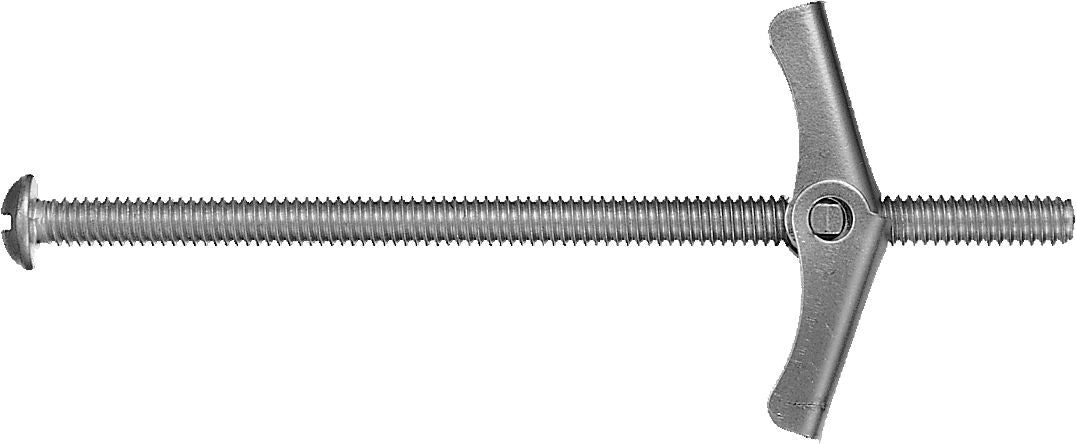

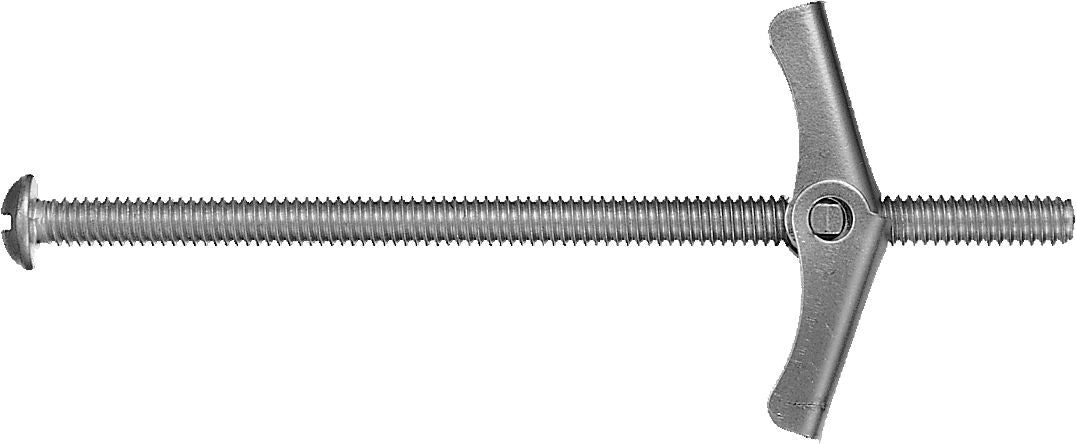

Wing-Type Toggle Bolt Anchor Steel 1/4-20 x 3"

Couldn't load pickup availability

SAE Flat Washer Thru-Hardened Steel 1/4"

Couldn't load pickup availability

Hex Nut Grade 8 Alloy Steel 1/2-13

Couldn't load pickup availability

Locknut with Nylon Insert Grade 8 5/16-18

Couldn't load pickup availability

Nylon Cable Tie 4" Black

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 5/16"

Couldn't load pickup availability

Autobahn Ergo Magna EZ Crimper Ratcheting Terminal Crimper

Couldn't load pickup availability

Masonry Sleeve Anchor Steel 1/4 x 1-3/8"

Couldn't load pickup availability

Sleeve Type Stud Bolt Anchor Steel 1/2 x 3"

Couldn't load pickup availability

Masonry Sleeve Anchor Steel 1/2 x 3"

Couldn't load pickup availability

Product Description

• 8.8 metric grade steel with yellow dichromate zinc plating• Exceptional strength coupled with the ability to resist vibratory loads

• Designed to equally distribute force to all sides

• Center plastic ring prevents anchor from spinning during installation

• Stud version can be adjusted for standoff height (shimming and leveling)

• Hex bolt version for applications where a finished appearance is required

• Removable; no cutting required

• Collapsible sleeve allows for secure clamping force

• Heavy-duty expansion sleeve provides follow-up expansion for fastening in tension zones of concrete such as under bridge decks, floor slabs and beams

• Designed for seismic (subject to or caused by an earthquake, vibration, strong impact or earth shaking) and dynamic (constant applied load) applications

• Applications include heavy machinery, conveyors, safety railings, dock bumpers and connecting structural components

Installation Procedure

1. Drill hole to correct diameter and depth.

2. Remove dust and rubble from hole with compressed air and a brush.

3. Using a hammer, tap the anchor through the material to be fastened until the anchor is firmly seated.

4. Tighten the anchor to the specified torque.

*Maximum values shown; use one-fourth of the ultimate tensile and shear capacities for the recommended 4:1 safety factor.

Technical Specifications

| Item#: | 50504 |

|---|---|

| Length | 100 mm |

| Type | Hi-Load Masonry Anchor |

| Drill Size | 14 mm |

| Material | Carbon Steel |

| Maximum Fastened Material Thickness | 25 mm |

| Reommended Torque | 36 ft·lbf |

| Size | M10X100MM mm |

| Minimum Embedment | 73 mm |

| Ultimate Shear Strength 4,000 PSI Concrete | 8,905 lb |

| Diameter | M10 |

| Ultimate Tensile Strength 4,000 PSI Concrete | 6,788 lb |

| UNSPSC #: | 31162101 |

| TAA Compliant: | Yes |

| Weight: | 0.54 lb |