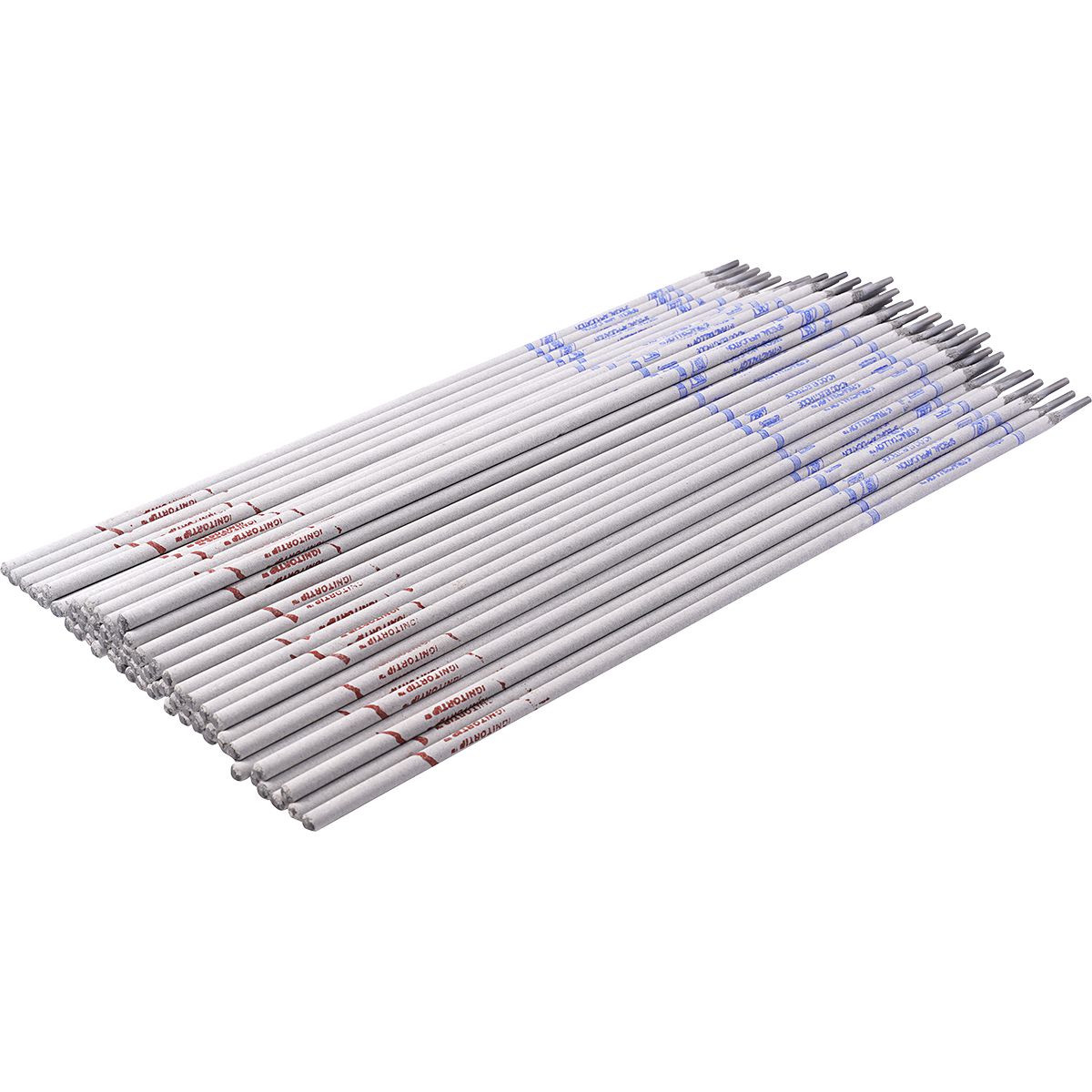

54 Aluminum Flux Cored Brazing Rod, 32" Length, 1/8"

(Pack of

2)

SKU:CW1857 Item#: CW1857

Transform your aluminum welding projects with the 54 Aluminum Flux Cored Brazing Rod, engineered specifically for joining all types of aluminum with professional-grade results. This flux-cored rod eliminates the guesswork from your welding process, delivering consistent, strong joints with 34,500 PSI tensile strength at an application temperature of 1,110°F. Whether you're working on aluminum frames, tubing systems, ornamental pieces, or cast aluminum repairs, this versatile rod applies easily and creates durable bonds that stand up to demanding conditions. Built for both joining and buildup applications, it streamlines your workflow while ensuring every weld meets the highest standards of strength and reliability.

• Products for joining and buildup

• Easy to apply

• Flux-cored for all types of aluminum

Tensile Strength: 34,500 PSIApplication Temperature: 1,110°F (599°C)Recommended Flux: F56 (if needed)

Typical Applications

• Aluminum frames

• Tubing and piping

• Ornamental aluminum

• Cast aluminum

Usage ProcedureBevel heavy sections to allow 100% weld metal penetration. Broadly heat area to be brazed with a large, soft and slightly carburizing flame to about 1,050°F (566°C). Warm the end of the rod and rub on base metal until flux flows freely. 54C will then begin to wet the base metal. Deposit the 54C to fill the joint. Flux residue may be removed with warm water and brush. If additional flux is needed, use F56 flux.

Couldn't load pickup availability

Catalog page#: 13-29

Frequently Bought Together

53 Pot Metal Bare Brazing Rod 1/8"

Couldn't load pickup availability

266 Pink Flux Coated Super Fast Flowing Silver Brasing Alloy 3/32x18

Couldn't load pickup availability

53 Pot Metal Bare Brazing Rod 1/8"

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 5/16"

Couldn't load pickup availability

Self-Drilling Screw Hex Head 1/4-14 x 1"

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 3/8"

Couldn't load pickup availability

X-Tractalloy Extracting Welding Electrode Non-Conductive Flux 3/32

Couldn't load pickup availability

Round Soapstone Holder Heavy Duty

Couldn't load pickup availability

Round Soapstone 1/4 x 5"

Couldn't load pickup availability

Product Description

Transform your aluminum welding projects with the 54 Aluminum Flux Cored Brazing Rod, engineered specifically for joining all types of aluminum with professional-grade results. This flux-cored rod eliminates the guesswork from your welding process, delivering consistent, strong joints with 34,500 PSI tensile strength at an application temperature of 1,110°F. Whether you're working on aluminum frames, tubing systems, ornamental pieces, or cast aluminum repairs, this versatile rod applies easily and creates durable bonds that stand up to demanding conditions. Built for both joining and buildup applications, it streamlines your workflow while ensuring every weld meets the highest standards of strength and reliability.• Products for joining and buildup

• Easy to apply

• Flux-cored for all types of aluminum

Tensile Strength: 34,500 PSIApplication Temperature: 1,110°F (599°C)Recommended Flux: F56 (if needed)

Typical Applications

• Aluminum frames

• Tubing and piping

• Ornamental aluminum

• Cast aluminum

Usage ProcedureBevel heavy sections to allow 100% weld metal penetration. Broadly heat area to be brazed with a large, soft and slightly carburizing flame to about 1,050°F (566°C). Warm the end of the rod and rub on base metal until flux flows freely. 54C will then begin to wet the base metal. Deposit the 54C to fill the joint. Flux residue may be removed with warm water and brush. If additional flux is needed, use F56 flux.

Technical Specifications

| Item#: | CW1857 |

|---|---|

| Welding Process | Brazing |

| Type | Flux Cored |

| Diameter | 1/8 " |

| Length | 32 " |

| Tensile Strength | 34,500 PSI |

| Melting Temperature | 1560-2000 °F |

| Base Metal | Aluminum |

| Recommended Flux | F56 |

| UNSPSC #: | 23271804 |

| TAA Compliant: | Yes |

| Weight: | 2.5 lb |