7109 Austenitic Hard Facing MIG Welding Wire, Flux Cored, DCRP Polarity, Quiet and Minimal Sparks, 0.045"

(Pack of

25)

SKU:CW3587 Item#: CW3587

Designed for low abrasion resistance and high impact situations.

Superior Advantages

• Work hardens under heavy impact conditions

• Unlimited pass-over-pass applications

• High operator appeal – smooth running, quiet and minimal sparks

Buildup and joining of manganese steels and carbon steels

Hardness: Up to Rc 54 (3rd pass)No. of Passes: Up to threePolarity: DC ReverseGas: None or 75% Ar, 25% CO2

Typical Applications

• Bucket teeth

• Hammer mill and mill swing hammers

• Tampers and jackhammers

• Impactor crusher bars

Usage ProcedureWhen CRONALLOY EAGLE 7109M-FC is applied via the open arc method, high deposition rates are possible. Weld current of 28-30V/250A will give a deposition of approximately 12lbs./hr.DC current, reverse polarity is preferred for better arc stability. For general hardfacing, wire stickout may vary from 3/4" to 1-1/2". On low current applications (175 – 240 amps), approximately 1" stickout should be maintained.The hardness figures shown are typical, and variations, higher or lowe

Frequently Bought Together

675 Hi Brade Fc High Abrasion Moderate Impact .045X33LB SELF-SHIELD

Couldn't load pickup availability

777 Austenitic Hard Facing Stick Electrode 5/32"

Couldn't load pickup availability

750 Martensitic Stick Rod Electrode 5/32"

Couldn't load pickup availability

194 High Impact Manganese Steel Alloy 3/16

Couldn't load pickup availability

Flat Washer Grade 12 Thru-Hardened Steel M8

Couldn't load pickup availability

PTO Pin Lock 1/4 x 2-1/2"

Couldn't load pickup availability

SAE Flat Washer Thru-Hardened Steel 5/16"

Couldn't load pickup availability

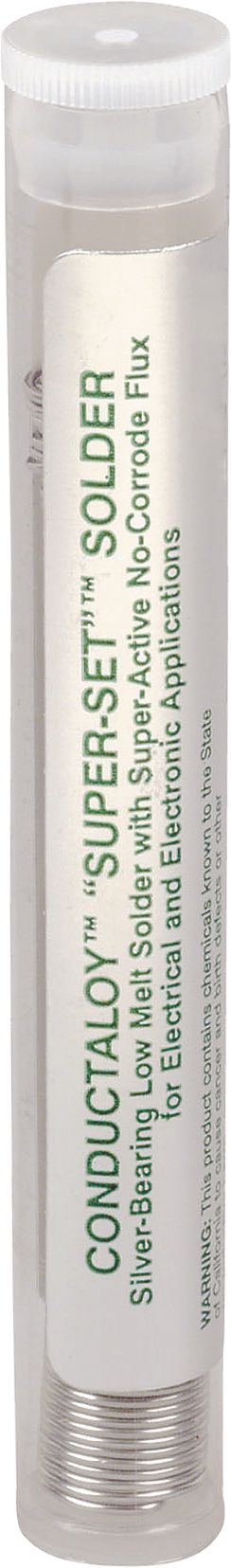

Rosin Core Solder 1/16"

Couldn't load pickup availability

Oxygen Safety Cap Heavy Duty

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder 1/4X4X5

Couldn't load pickup availability

Product Description

Designed for low abrasion resistance and high impact situations.Superior Advantages

• Work hardens under heavy impact conditions

• Unlimited pass-over-pass applications

• High operator appeal – smooth running, quiet and minimal sparks

Buildup and joining of manganese steels and carbon steels

Hardness: Up to Rc 54 (3rd pass)No. of Passes: Up to threePolarity: DC ReverseGas: None or 75% Ar, 25% CO2

Typical Applications

• Bucket teeth

• Hammer mill and mill swing hammers

• Tampers and jackhammers

• Impactor crusher bars

Usage ProcedureWhen CRONALLOY EAGLE 7109M-FC is applied via the open arc method, high deposition rates are possible. Weld current of 28-30V/250A will give a deposition of approximately 12lbs./hr.DC current, reverse polarity is preferred for better arc stability. For general hardfacing, wire stickout may vary from 3/4" to 1-1/2". On low current applications (175 – 240 amps), approximately 1" stickout should be maintained.The hardness figures shown are typical, and variations, higher or lowe

Technical Specifications

| Item#: | CW3587 |

|---|---|

| Welding Process | MIG |

| Type | Flux Cored |

| Diameter | .045 " |

| Base Metal | Austenitic |

| Hardness | 45-54 (WH) HRC |

| Shielding Gas | No Gas |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 27.5 lb |

Product Restrictions