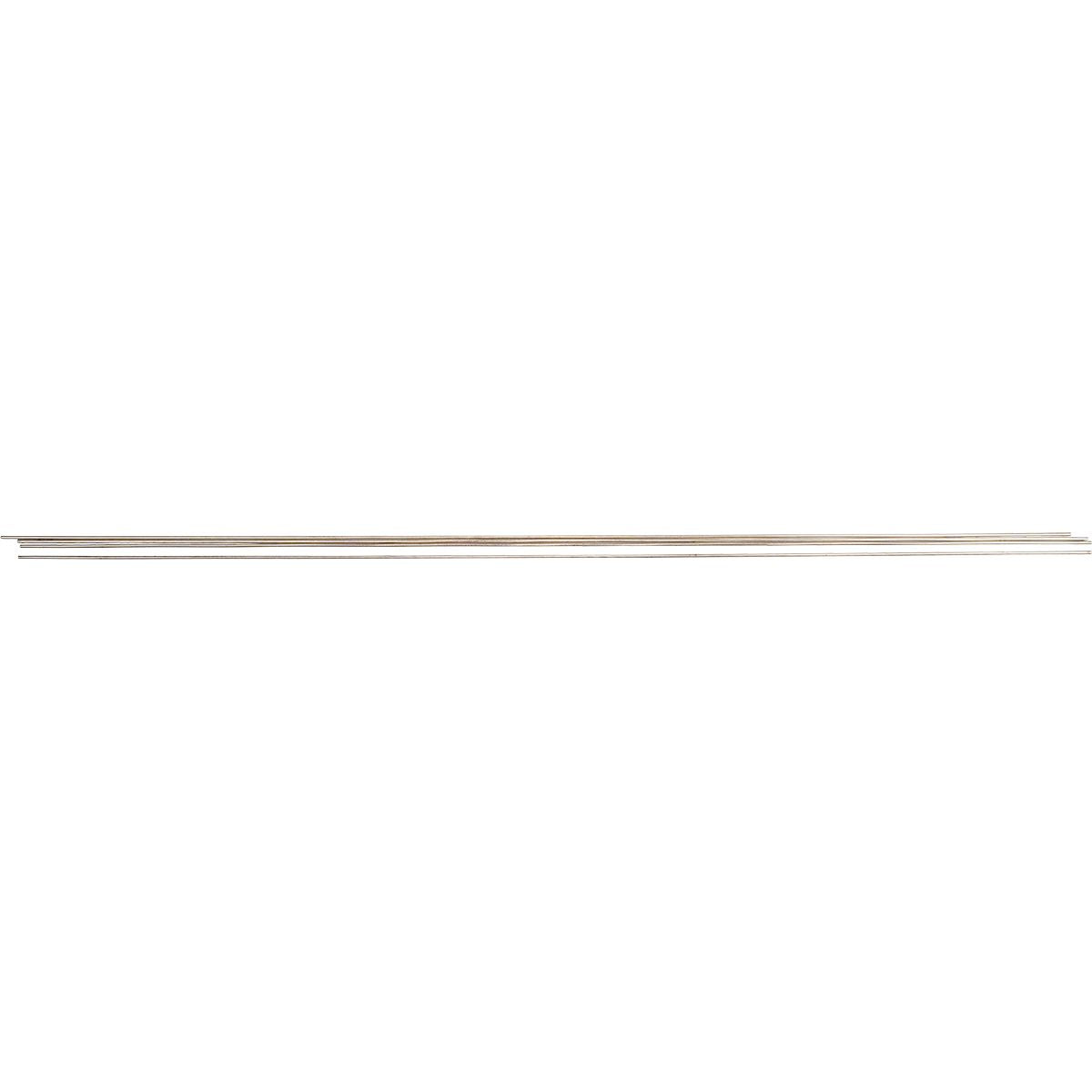

45 Silver Bare Brazing Rod, Copper/Silver, 0.05" Width, 18" Length, 1/8" Diameter

(Pack of

1)

SKU:CW1013 Item#: CW1013

These “sil-phos” alloys provide cost-effective solutions to joining copper and brass alloys.

Superior Advantages

• Thin flow provides excellent capillary action

• No flux required for copper-to-copper applications

• Fills gaps on poor fit-up joints

Resists vibration, shock, impact

Brazing Range: 1,300°F to 1,450°F (704°C to 788°C)Recommended Flux: F40 (for dissimilar)

Typical Applications

• Electrical components

• Plumbing and HVAC

• Copper coils and tubing

• Rotors and armatures

Usage ProcedureHeat broad area using large torch tip; a neutral flame is suggested, and a distance of 2" to 3" from the base metal produces the best results. No flux is required on copper-to-copper welds. The joint area should be clean. When the copper turns dull red, the alloy should be applied and the flame should be kept in constant motion ahead of the rod. These alloys are especially effective on long lap joints, fillets and butts.

Couldn't load pickup availability

Catalog page#: 13-28

Frequently Bought Together

261 Blue Flux Coated General Purpose Silver Brazing Alloy 1/16X18

Couldn't load pickup availability

265 Bare Silver Free Flowing Copper Alloy .050X20

Couldn't load pickup availability

264 Bare High Silver Cadium Free Alloy 1/16x18

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 3/8"

Couldn't load pickup availability

Nylon Cable Tie 4" Black

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 5/16"

Couldn't load pickup availability

266 Pink Flux Coated Super Fast Flowing Silver Brasing Alloy 3/32x18

Couldn't load pickup availability

Rosin Core Solder 1/16"

Couldn't load pickup availability

22-50 MIG Welding Nozzle 1/2"

Couldn't load pickup availability

Solid Solder 1/32"

Couldn't load pickup availability

Product Description

These “sil-phos” alloys provide cost-effective solutions to joining copper and brass alloys.Superior Advantages

• Thin flow provides excellent capillary action

• No flux required for copper-to-copper applications

• Fills gaps on poor fit-up joints

Resists vibration, shock, impact

Brazing Range: 1,300°F to 1,450°F (704°C to 788°C)Recommended Flux: F40 (for dissimilar)

Typical Applications

• Electrical components

• Plumbing and HVAC

• Copper coils and tubing

• Rotors and armatures

Usage ProcedureHeat broad area using large torch tip; a neutral flame is suggested, and a distance of 2" to 3" from the base metal produces the best results. No flux is required on copper-to-copper welds. The joint area should be clean. When the copper turns dull red, the alloy should be applied and the flame should be kept in constant motion ahead of the rod. These alloys are especially effective on long lap joints, fillets and butts.

Technical Specifications

| Item#: | CW1013 |

|---|---|

| Welding Process | Brazing |

| Type | Bare |

| Diameter | 1/8 " |

| Length | 18 " |

| Width | .050 " |

| Melting Temperature | 1300-1450 °F |

| Color | Copper/Silver |

| Base Metal | Silver |

| Silver Content | Low |

| Recommended Flux | F40 |

| Description | Low Silver |

| UNSPSC #: | 23271804 |

| TAA Compliant: | Yes |

| Weight: | 1.38 lb |