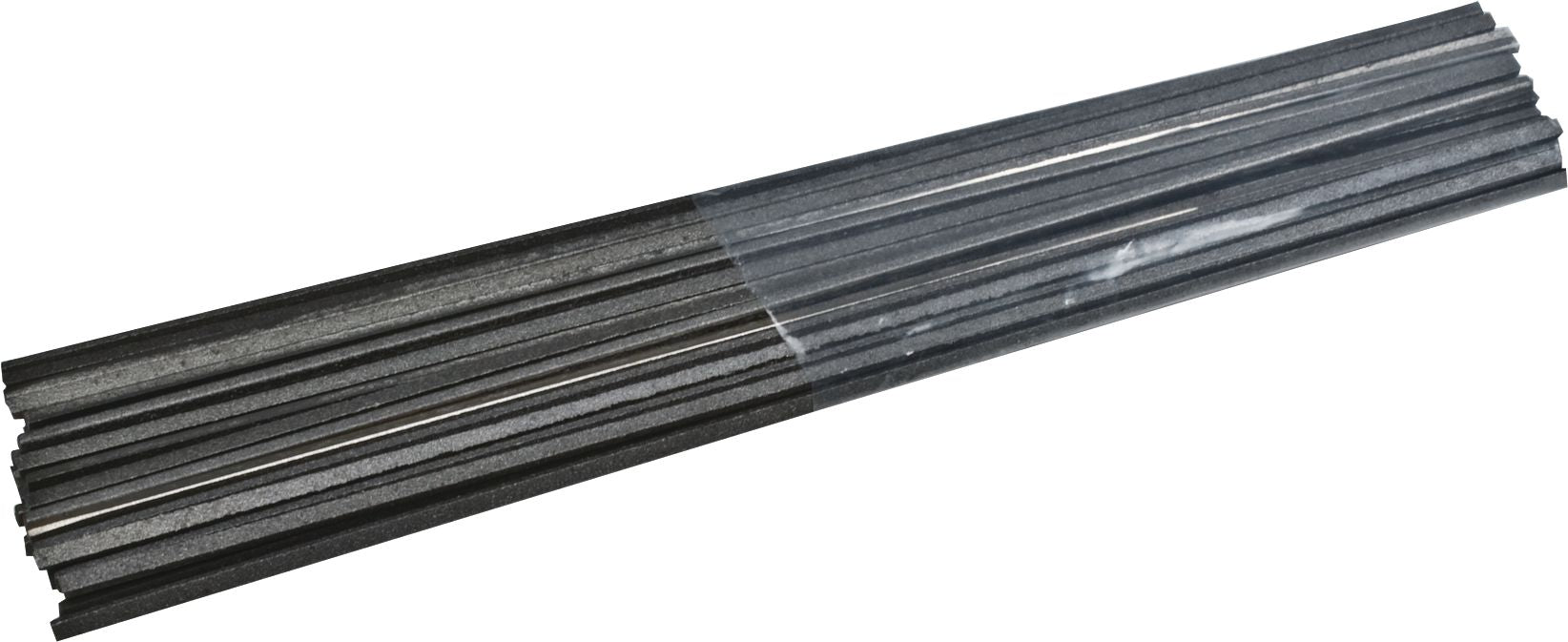

44 Silver Bare Brazing Rod, Copper/Silver, 36"Length, 3/32"

(Pack of

2)

SKU:CW1012 Item#: CW1012

Tackle your welding projects with the 54 Al44 Silver Bare Brazing Rod, engineered specifically for copper and brass applications that demand both strength and precision. This high-performance rod delivers superior joint integrity while offering significant cost savings compared to traditional silver alloys, making it the smart choice for professional welders who refuse to compromise on quality. Operating within a brazing range of 1,350°F to 1,550°F, it excels in electrical contacts, copper wire splicing, and brass fittings with a color match that ensures seamless, professional-looking results. Whether you're joining copper pipes or bonding copper to steel, this reliable brazing rod provides the durability and performance your welding projects deserve.

• High strength

• Lower cost compared to silver alloys

• Good color match

Brazing Range: 1,350°F to 1,550°F (732°C to 843°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical contacts

• Copper wire splicing

• Brass and bronze fittings

• Copper pipes

• Copper to steel

Usage ProcedureUse a slightly carburizing flame to obtain a free-flowing bead. Cronabraze™ 44 does not require fusion of the base metal. For joining copper to copper, no flux is required, but with brass or bronze, F40 flux is needed for a strong, sure bond. It is recommended that 2" to 3" of distance be maintained between the flame cone and the base metal for best results.

Couldn't load pickup availability

Catalog page#: 13-30

Frequently Bought Together

54 Aluminum Flux Cored Brazing Rod 1/8"

Couldn't load pickup availability

22 Cast Iron Bare Brazing Rod 3/16"

Couldn't load pickup availability

30 Copper and Steel Flux Coated Brazing Rod 3/32"

Couldn't load pickup availability

44 Silver Bare Brazing Rod 1/16"

Couldn't load pickup availability

201 The Elite Blue Flux Coated Brazing Alloy 1/16

Couldn't load pickup availability

202Xl Red Flux Coated Brazing Alloy 3/16

Couldn't load pickup availability

Autobahn Ergo Magna EZ Crimper Ratcheting Terminal Crimper

Couldn't load pickup availability

18" Locking Smooth Operator Clamp

Couldn't load pickup availability

Master Series Penlight Flashlight

Couldn't load pickup availability

Nylon Cable Tie 15.25" Black

Couldn't load pickup availability

Nylon Cable Tie 11.75" Black

Couldn't load pickup availability

Nylon Cable Tie 15.5" Black

Couldn't load pickup availability

Flat Soapstone 1/2"

Couldn't load pickup availability

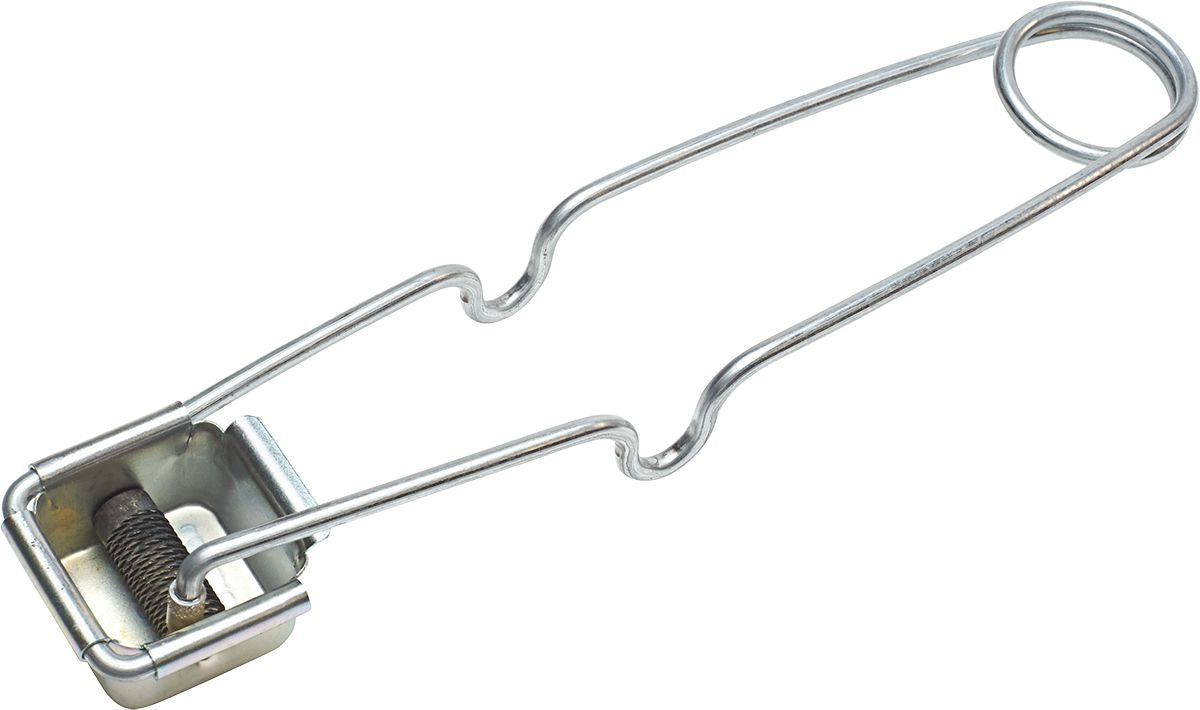

Oxy Acetylene Fuel Gas Single Flint Striker

Couldn't load pickup availability

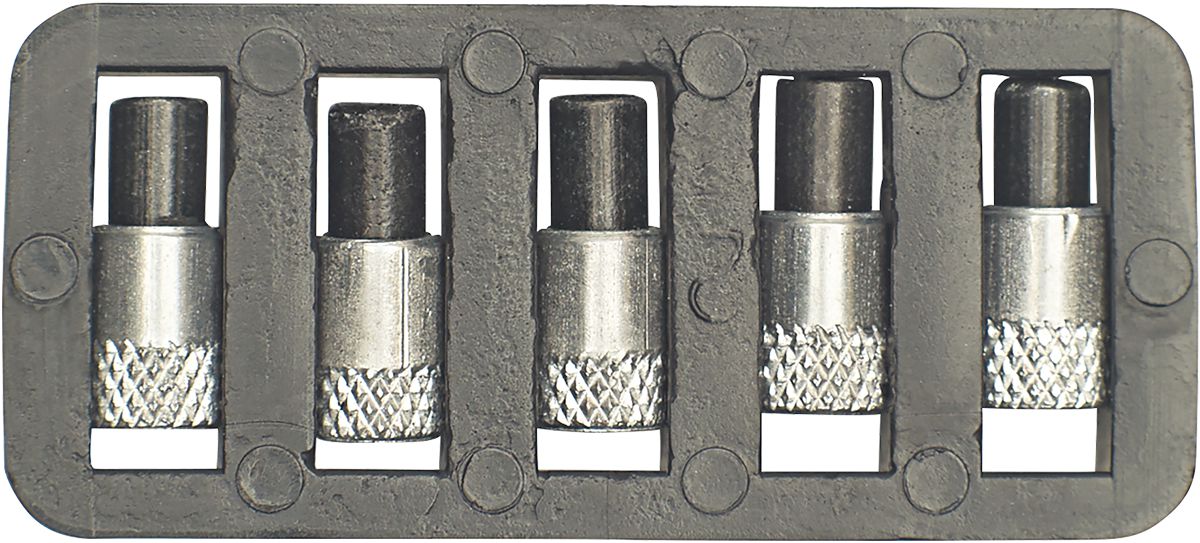

Oxy Acetylene Fuel Gas Single Replacement Flint

Couldn't load pickup availability

Product Description

Tackle your welding projects with the 54 Al44 Silver Bare Brazing Rod, engineered specifically for copper and brass applications that demand both strength and precision. This high-performance rod delivers superior joint integrity while offering significant cost savings compared to traditional silver alloys, making it the smart choice for professional welders who refuse to compromise on quality. Operating within a brazing range of 1,350°F to 1,550°F, it excels in electrical contacts, copper wire splicing, and brass fittings with a color match that ensures seamless, professional-looking results. Whether you're joining copper pipes or bonding copper to steel, this reliable brazing rod provides the durability and performance your welding projects deserve.• High strength

• Lower cost compared to silver alloys

• Good color match

Brazing Range: 1,350°F to 1,550°F (732°C to 843°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical contacts

• Copper wire splicing

• Brass and bronze fittings

• Copper pipes

• Copper to steel

Usage ProcedureUse a slightly carburizing flame to obtain a free-flowing bead. Cronabraze™ 44 does not require fusion of the base metal. For joining copper to copper, no flux is required, but with brass or bronze, F40 flux is needed for a strong, sure bond. It is recommended that 2" to 3" of distance be maintained between the flame cone and the base metal for best results.

Technical Specifications

| Item#: | CW1012 |

|---|---|

| Welding Process | Brazing |

| Type | Bare |

| Diameter | 3/32 " |

| Length | 36 " |

| Melting Temperature | 1350-1550 °F |

| Color | Copper |

| Base Metal | Silver |

| Recommended Flux | F40 |

| Description | Copper/Brass |

| UNSPSC #: | 23271804 |

| TAA Compliant: | Yes |

| Weight: | 2.0 lb |