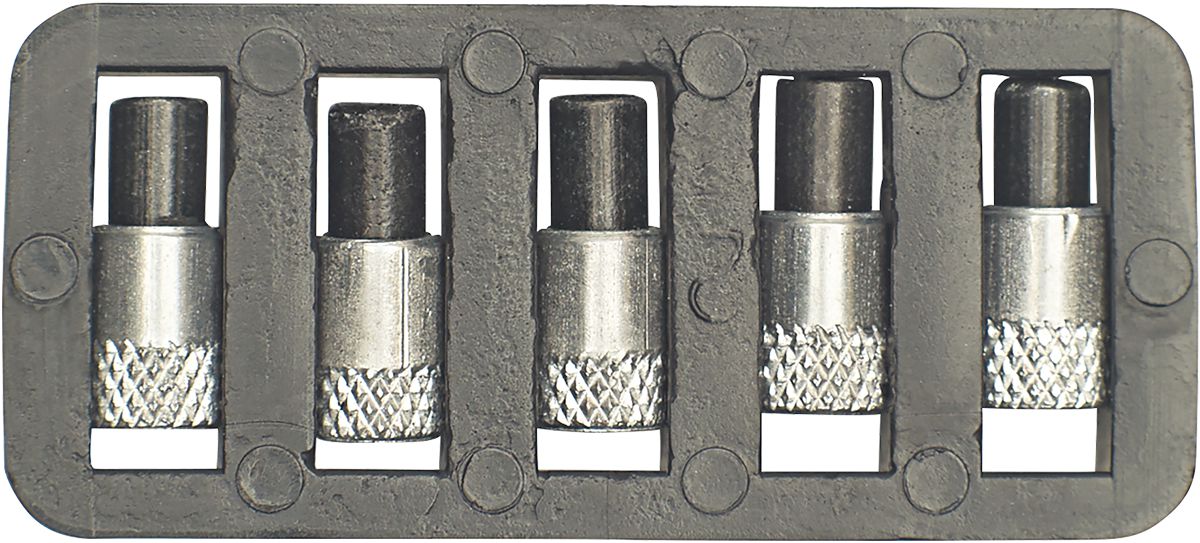

178 Outstanding Abrasion Resitance At High Temparature At 1400F Complex Carbides Polarity Dcep Harness 63-66Rc Number Of Passes 2

(Pack of

5)

SKU:EG17800375 Item#: EG17800375

• Ultra-Brade SD utilizes a complex carbide alloy system that provides outstanding abrasion resistance even at high temperatures.

• Tubular electrode design provides 90% deposition efficiency

• Reduces smoke by half compared to conventional hardfacing electrodes

• Runs at lower amperage — reduces distortion, weld dilution andmetal fatigue

• Hardness of up to 66 Rc, one layer can outlast two layers of competitive product

• Designed to withstand extreme temperature abrasion up to 1400˚F (760˚C)

• Not designed for impact resistance

• Hardness: 63-66 Rc (deposits will relief check crack readily) • Max deposit thickness: 2 layersCurrent: DCEP (DC+) or AC • Abrasion resistance: Excellent • ASTM G65 Procedure A (Dry sand rubber wheel abrasion test):- 10.51 mm3 volume loss- 0.072 gm mass loss • For comparison sintered tungsten carbide: 0.039 to 0.080 gm mass loss

Frequently Bought Together

7770 Hard Facing Buildup Stick Rod Electrode 1/8"

Couldn't load pickup availability

676 Flux Core Wire Extreme Abrasion Moderate Impact .045X33LBS

Couldn't load pickup availability

7770 Hard Facing Buildup Stick Rod Electrode 3/16"

Couldn't load pickup availability

7222 Carbide Hard Facing Stick Rod Electrode 1/4"

Couldn't load pickup availability

7220 Carbide Hard Facing Stick Rod Electrode 1/2"

Couldn't load pickup availability

711 Carbide Hard Facing Stick Rod Electrode 3/16"

Couldn't load pickup availability

Nylon Cable Tie 15.5" Black

Couldn't load pickup availability

Butt Connector 16 to 14 AWG Clear

Couldn't load pickup availability

Butt Connector 22 to 18 AWG Clear

Couldn't load pickup availability

Oxy Acetylene Fuel Gas Single Replacement Flint

Couldn't load pickup availability

176 Extreme Abrasion With Impact 1/4X18IN

Couldn't load pickup availability

Rosin Core Solder 0.032"

Couldn't load pickup availability

Product Description

• Ultra-Brade SD utilizes a complex carbide alloy system that provides outstanding abrasion resistance even at high temperatures.• Tubular electrode design provides 90% deposition efficiency

• Reduces smoke by half compared to conventional hardfacing electrodes

• Runs at lower amperage — reduces distortion, weld dilution andmetal fatigue

• Hardness of up to 66 Rc, one layer can outlast two layers of competitive product

• Designed to withstand extreme temperature abrasion up to 1400˚F (760˚C)

• Not designed for impact resistance

• Hardness: 63-66 Rc (deposits will relief check crack readily) • Max deposit thickness: 2 layersCurrent: DCEP (DC+) or AC • Abrasion resistance: Excellent • ASTM G65 Procedure A (Dry sand rubber wheel abrasion test):- 10.51 mm3 volume loss- 0.072 gm mass loss • For comparison sintered tungsten carbide: 0.039 to 0.080 gm mass loss

Technical Specifications

| Item#: | EG17800375 |

|---|---|

| Welding Process | Stick |

| Type | Electrode |

| Diameter | 3/8 " |

| Length | 18 " |

| Base Metal | Steel To Steel |

| Hardness | 63-66 HRC |

| Polarity | DCEP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 6.17 lb |