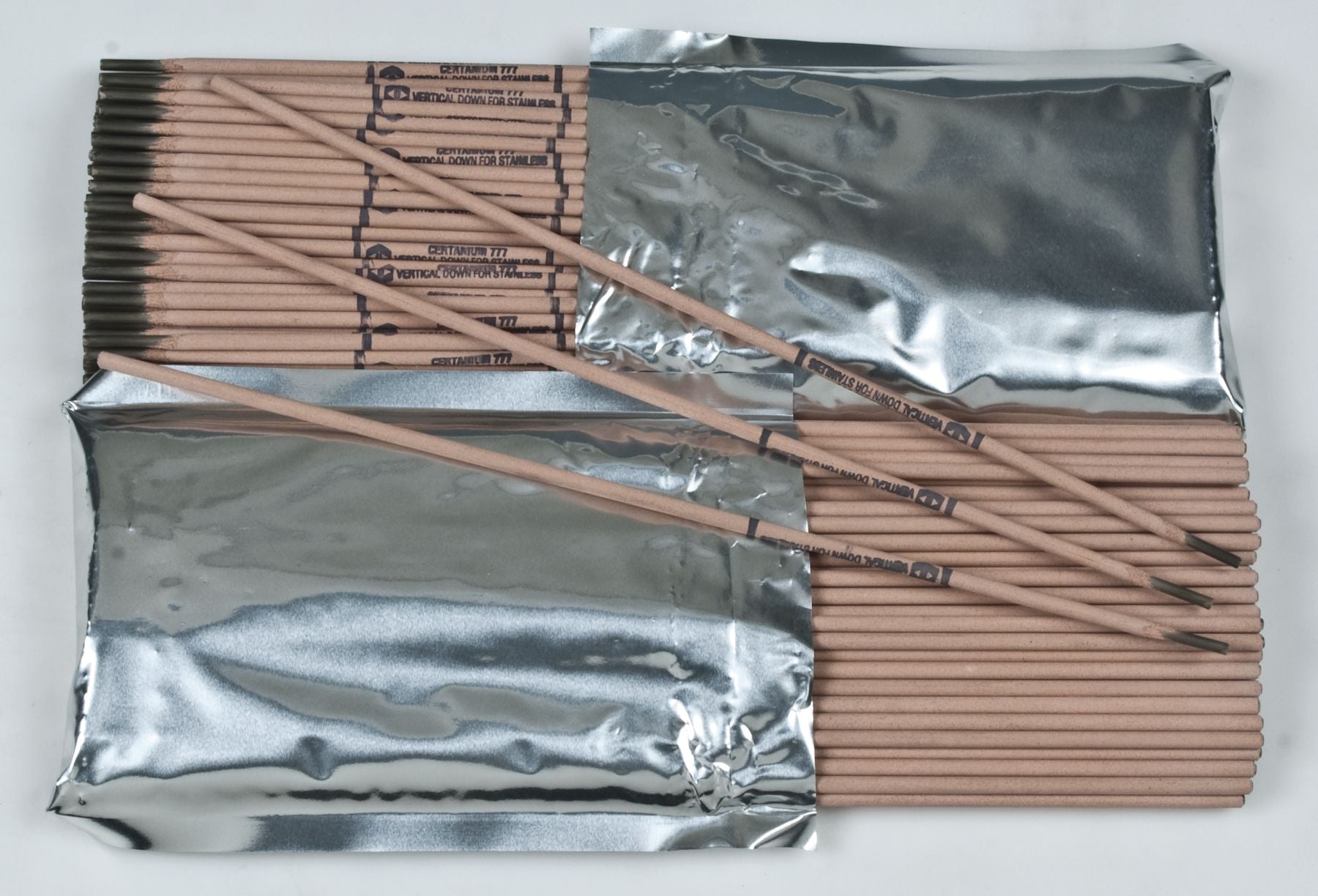

340 Chro-moly Stick Rod Electrode, Flux Coated, 40 HRC Hardness, 25% Elongation, 60 to 90 Amps, DCRP Polarity, 3/32"

(Pack of

5)

SKU:CW1028 Item#: CW1028

Specially formulated for welding the 400 Series martensitic stainless steels such as 410, 416 and 420. Primary alloying elements are chromium, nickel and molybdenum so it can also be used on chrome-moly tool steels.

Superior Advantages

• Produces smooth, dense, porosity- and crack-free weld deposits

• Resistant to moderate corrosion and heat scaling (up to 1,200°F)

• Hard with excellent machinability

• Ideally suited for high temperature applications (up to 800°F)

Tensile Strength: 140,000 PSIElongation: 25%Hardness: Rc 40Polarity: DC Reverse

Typical Applications

• Tubular frames and roll bars

• Forging dies

• Fractured tools and blades

• Shaft buildup

• Bearing surfaces

• Metal-to-metal wear

Usage ProcedureMaintain a short arc with minimal weave. Preheat as prescribed by base metal.

Frequently Bought Together

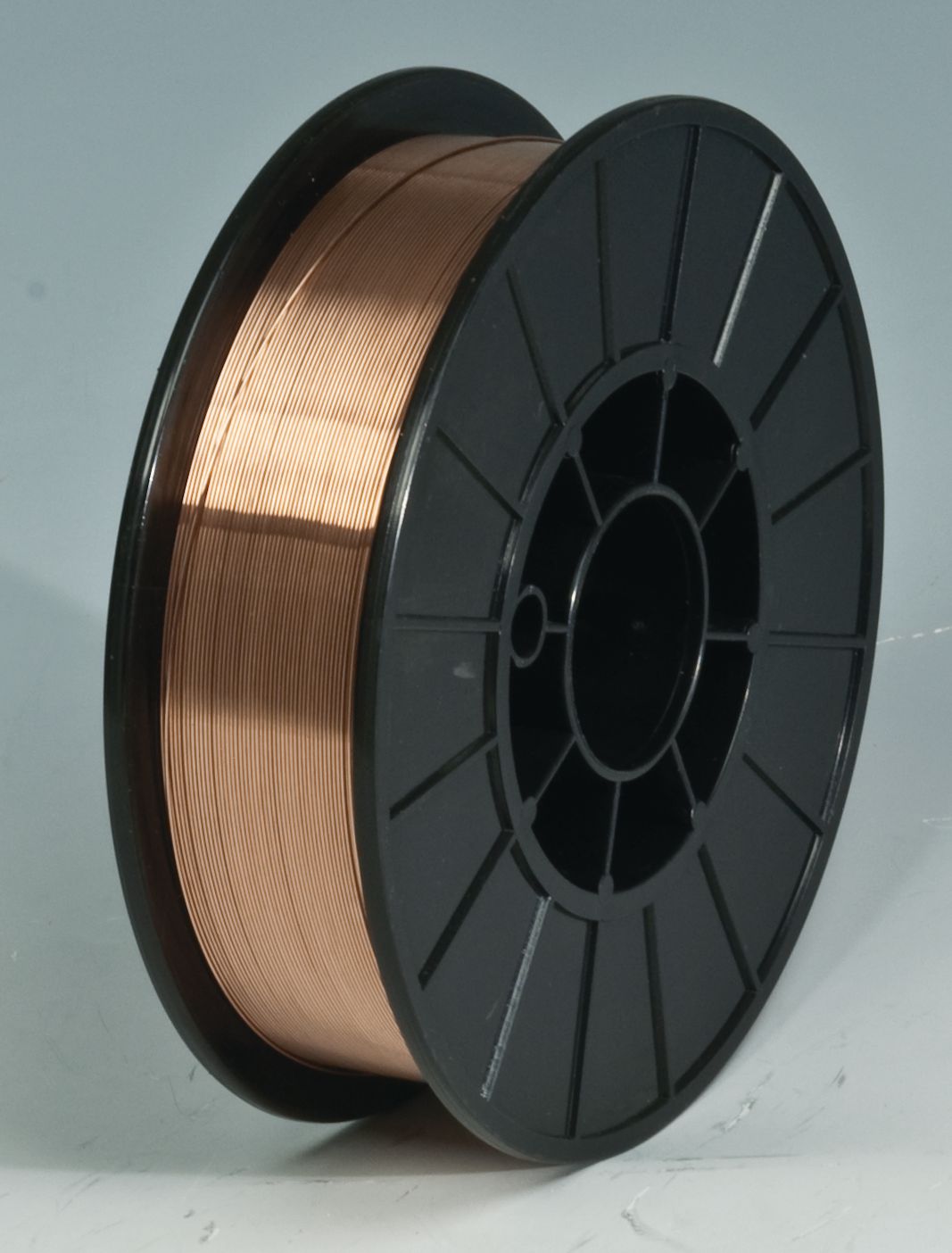

340 Chromoly TIG Wire 1/16"

Couldn't load pickup availability

340 Chro-moly Stick Rod Electrode 1/8"

Couldn't load pickup availability

107 Mild Steel High Penetration Low Alloy Electrode 5/32"

Couldn't load pickup availability

SAE J995C Locknut with Nylon Insert Grade 8 1/4-20

Couldn't load pickup availability

SAE J995C Locknut with Nylon Insert Grade 8 3/8-16

Couldn't load pickup availability

IFI 100/107 Top Locknut Grade C 5/8-11

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

344 Tool Steel TIG Wire 1/16"

Couldn't load pickup availability

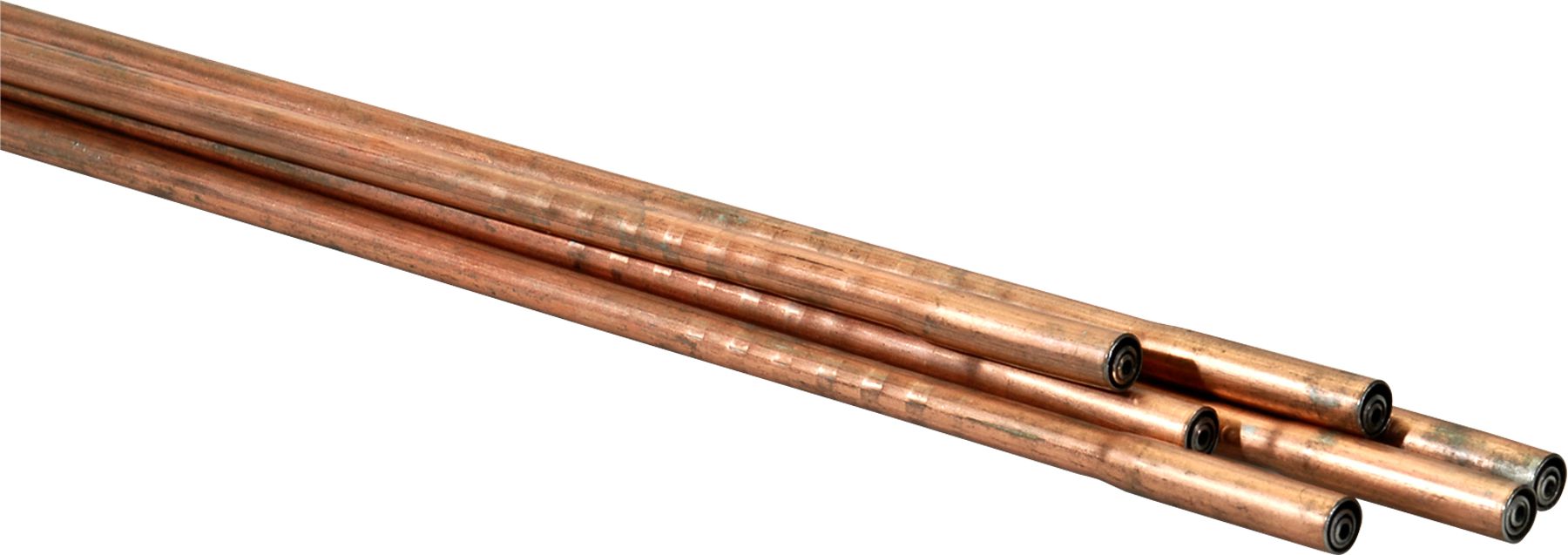

Oxy-Therm Cutting Rod 3/8 x 24"

Couldn't load pickup availability

777 Stainless Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

E6013 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

331 Mild and Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

Product Description

Specially formulated for welding the 400 Series martensitic stainless steels such as 410, 416 and 420. Primary alloying elements are chromium, nickel and molybdenum so it can also be used on chrome-moly tool steels.Superior Advantages

• Produces smooth, dense, porosity- and crack-free weld deposits

• Resistant to moderate corrosion and heat scaling (up to 1,200°F)

• Hard with excellent machinability

• Ideally suited for high temperature applications (up to 800°F)

Tensile Strength: 140,000 PSIElongation: 25%Hardness: Rc 40Polarity: DC Reverse

Typical Applications

• Tubular frames and roll bars

• Forging dies

• Fractured tools and blades

• Shaft buildup

• Bearing surfaces

• Metal-to-metal wear

Usage ProcedureMaintain a short arc with minimal weave. Preheat as prescribed by base metal.

Technical Specifications

| Item#: | CW1028 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 3/32 " |

| Tensile Strength | 140,000 PSI |

| Elongation | 25 % |

| Base Metal | Chro-moly |

| Hardness | 40 HRC |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.0 lb |

Product Restrictions