41 Silver Flux Coated Brazing Rod, Red, 18" Length, 1/16"

(Pack of

6)

SKU:CW1825 Item#: CW1825

With lower melting temperatures and better capillary action than low silver products, medium silver brazing alloys are excellent for joining copper, stainless steel, bronze alloys and nickel alloys.

Superior Advantages

• Thin-flowing for tight joints, yet fills and bridges gaps

• Strong and ductile

• Very good electrical conductivity

Low-temperature application

Flux Coating Color: RedTensile Strength: 80,000 PSIBrazing Range: 1,120°F to 1,150°F (604°C to 621°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical rotors, contacts and lugs

• Instrumentation and controls

• Plumbing

• Arts and crafts

• Stainless steel

Usage ProcedureMaterials should be smooth and free of burrs or uneven edges. A carburizing oxyacetylene flame should be used, heating a broad surface along the joint line. Keep the flame cone one inch ahead of the alloy rod and a continuous fillet will form. Clean flux residue off with water.

Frequently Bought Together

261 Blue Flux Coated General Purpose Silver Brazing Alloy 1/16X18

Couldn't load pickup availability

265 Bare Silver Free Flowing Copper Alloy .050X20

Couldn't load pickup availability

264 Bare High Silver Cadium Free Alloy 1/16x18

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 1/4"

Couldn't load pickup availability

SAE Flat Washer Thru-Hardened Steel 1/4"

Couldn't load pickup availability

Flat Washer Grade 12 Thru-Hardened Steel M8

Couldn't load pickup availability

40 High Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

266 Pink Flux Coated Super Fast Flowing Silver Brasing Alloy 1/16X18

Couldn't load pickup availability

47 Sil-Phos Bare Brazing Rod 1/8"

Couldn't load pickup availability

Round Soapstone 1/4 x 5"

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder 1/4X4X5

Couldn't load pickup availability

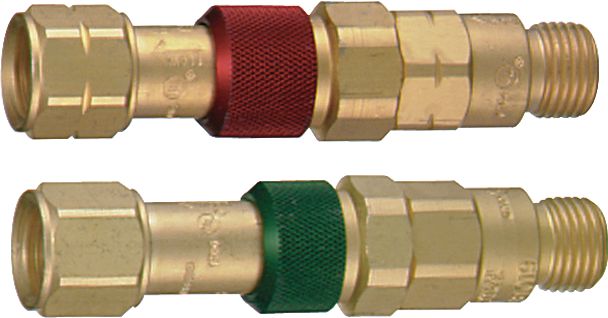

Oxy Acetylene Fuel and Oxygen Quick Connector

Couldn't load pickup availability

Product Description

With lower melting temperatures and better capillary action than low silver products, medium silver brazing alloys are excellent for joining copper, stainless steel, bronze alloys and nickel alloys.Superior Advantages

• Thin-flowing for tight joints, yet fills and bridges gaps

• Strong and ductile

• Very good electrical conductivity

Low-temperature application

Flux Coating Color: RedTensile Strength: 80,000 PSIBrazing Range: 1,120°F to 1,150°F (604°C to 621°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical rotors, contacts and lugs

• Instrumentation and controls

• Plumbing

• Arts and crafts

• Stainless steel

Usage ProcedureMaterials should be smooth and free of burrs or uneven edges. A carburizing oxyacetylene flame should be used, heating a broad surface along the joint line. Keep the flame cone one inch ahead of the alloy rod and a continuous fillet will form. Clean flux residue off with water.

Technical Specifications

| Item#: | CW1825 |

|---|---|

| Welding Process | Brazing |

| Type | Flux Coating |

| Diameter | 1/16 " |

| Length | 18 " |

| Tensile Strength | 80,000 PSI |

| Melting Temperature | 1120-1150 °F |

| Color | Red |

| Base Metal | Silver |

| Silver Content | Medium |

| Recommended Flux | F40 |

| Description | Medium Silver |

| UNSPSC #: | 23271804 |

| TAA Compliant: | Yes |

| Weight: | 0.48 lb |

Product Restrictions