H7 Carbide Hard Facing MIG Welding Wire, Flux Cored, 53 to 60 HRC Hardness, DCRP Polarity, Crushers and Hammers, 0.045"

(Pack of

25)

SKU:CW6081 Item#: CW6081

A selection of alloys to meet a broad spectrum of hardfacing needs in volume quantities.

Superior Advantages

• All VX wires are self-shielding, saving money on gas

• Our technical team will work closely with you to determine the best product for your specific application

Significant abrasion resistance with low impact characteristics

Specifications: Moderate chrome carbide CrCHardness: Rc 60No. of Passes: Up to three

Typical Applications

• Buckets and dozer blades

• Dump beds and truck liners

• Chutes and augers

• Crushers and hammers

Frequently Bought Together

7109 Austenitic Hard Facing Welding Wire 0.045"

Couldn't load pickup availability

675 Hi Brade Fc High Abrasion Moderate Impact .045X33LB SELF-SHIELD

Couldn't load pickup availability

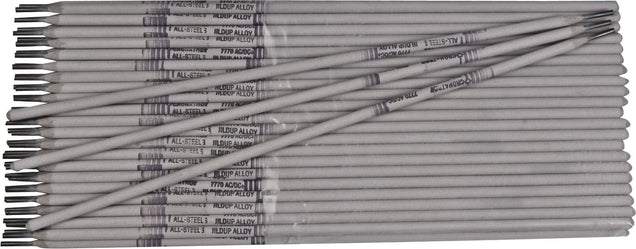

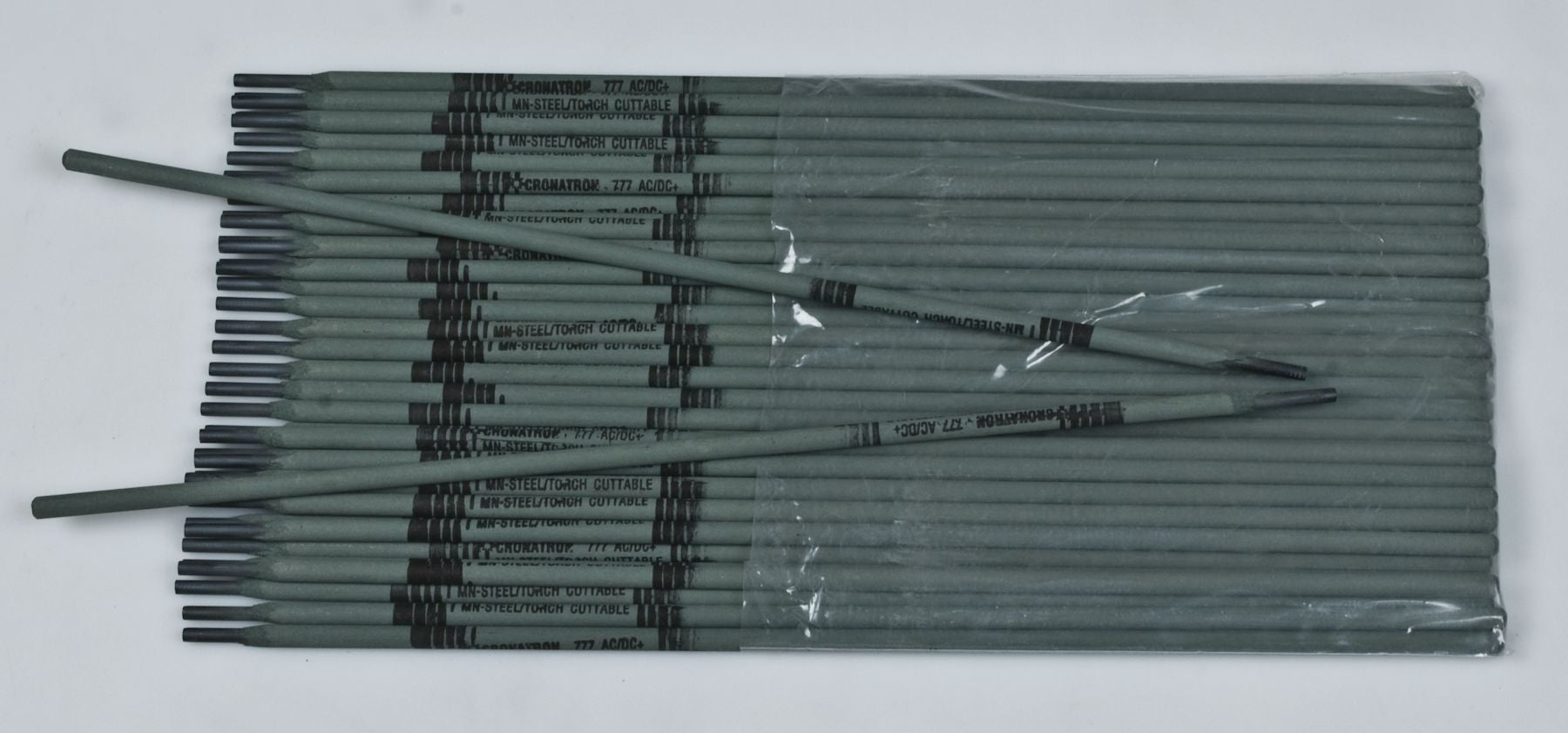

777 Austenitic Hard Facing Stick Electrode 5/32"

Couldn't load pickup availability

676 Flux Core Wire Extreme Abrasion Moderate Impact 1/16X33LBS

Couldn't load pickup availability

H4 Carbide Hard Facing MIG Welding Wire 0.045"

Couldn't load pickup availability

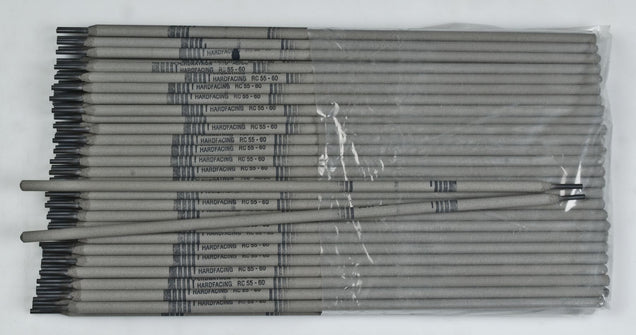

174 Gray High Abrasion Moderate Impact 3/32

Couldn't load pickup availability

Flat Washer Grade 12 Thru-Hardened Steel M8

Couldn't load pickup availability

PTO Pin Lock 1/4 x 2-1/2"

Couldn't load pickup availability

SAE Flat Washer Thru-Hardened Steel 5/16"

Couldn't load pickup availability

Rosin Core Solder 1/16"

Couldn't load pickup availability

Rosin Core Solder 1/16"

Couldn't load pickup availability

Oxygen Safety Cap Heavy Duty

Couldn't load pickup availability

Product Description

A selection of alloys to meet a broad spectrum of hardfacing needs in volume quantities.Superior Advantages

• All VX wires are self-shielding, saving money on gas

• Our technical team will work closely with you to determine the best product for your specific application

Significant abrasion resistance with low impact characteristics

Specifications: Moderate chrome carbide CrCHardness: Rc 60No. of Passes: Up to three

Typical Applications

• Buckets and dozer blades

• Dump beds and truck liners

• Chutes and augers

• Crushers and hammers

Technical Specifications

| Item#: | CW6081 |

|---|---|

| Welding Process | MIG |

| Type | Flux Cored |

| Diameter | .045 " |

| Base Metal | Carbide |

| Carbide Type | Chromium |

| Hardness | 53-60 HRC |

| Shielding Gas | No Gas |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 29.0 lb |

Product Restrictions