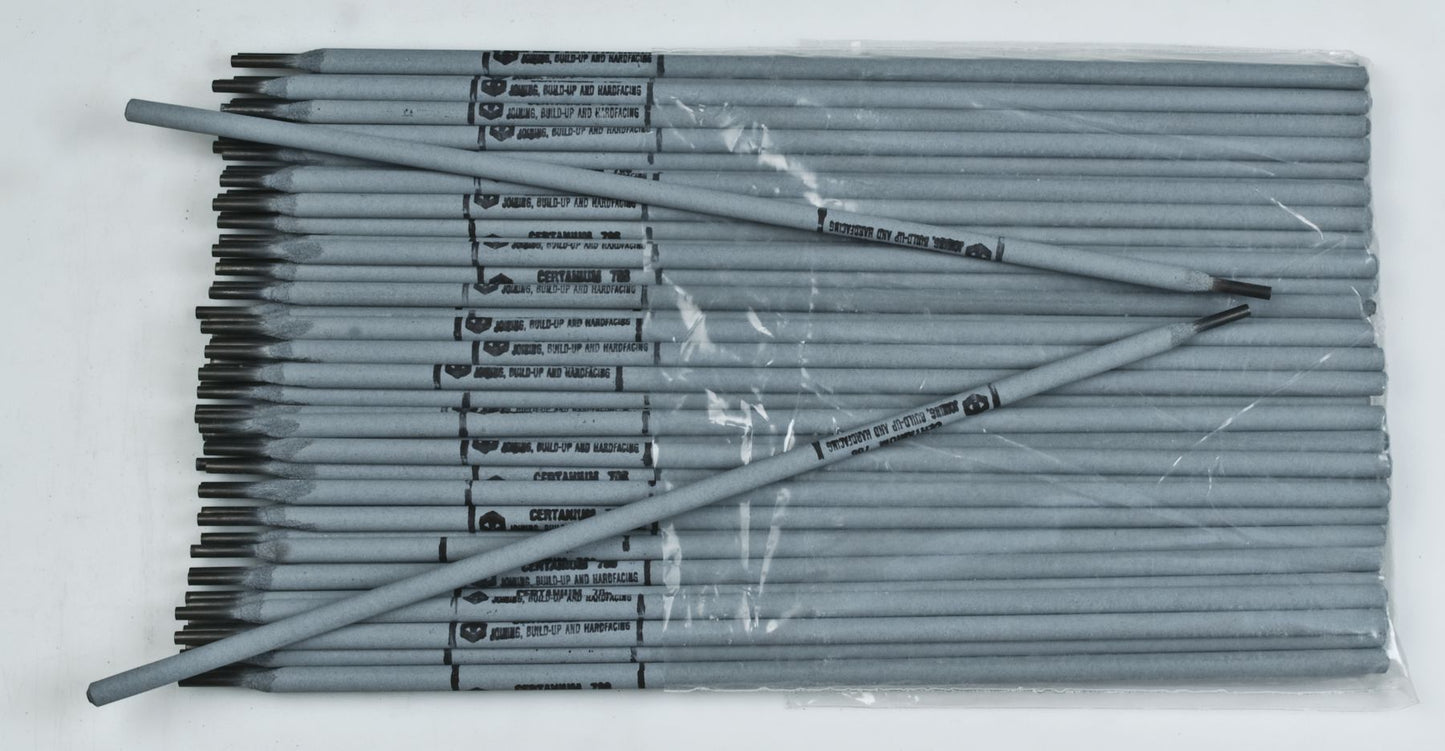

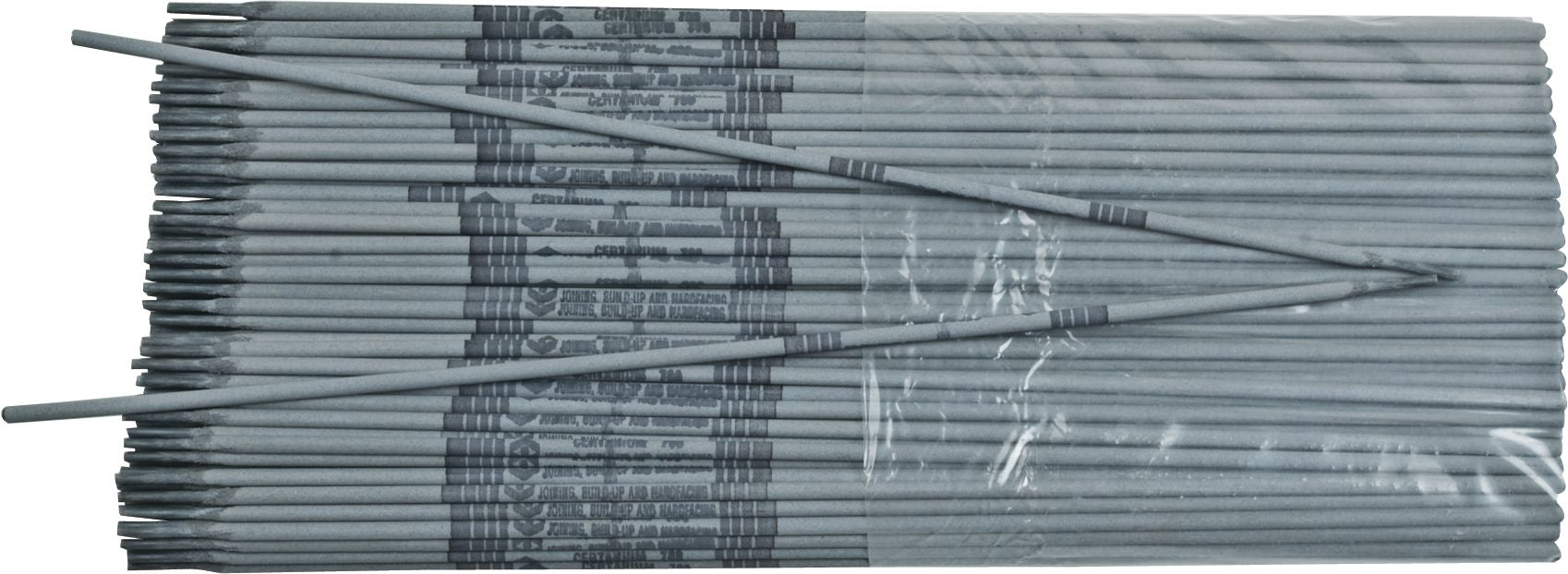

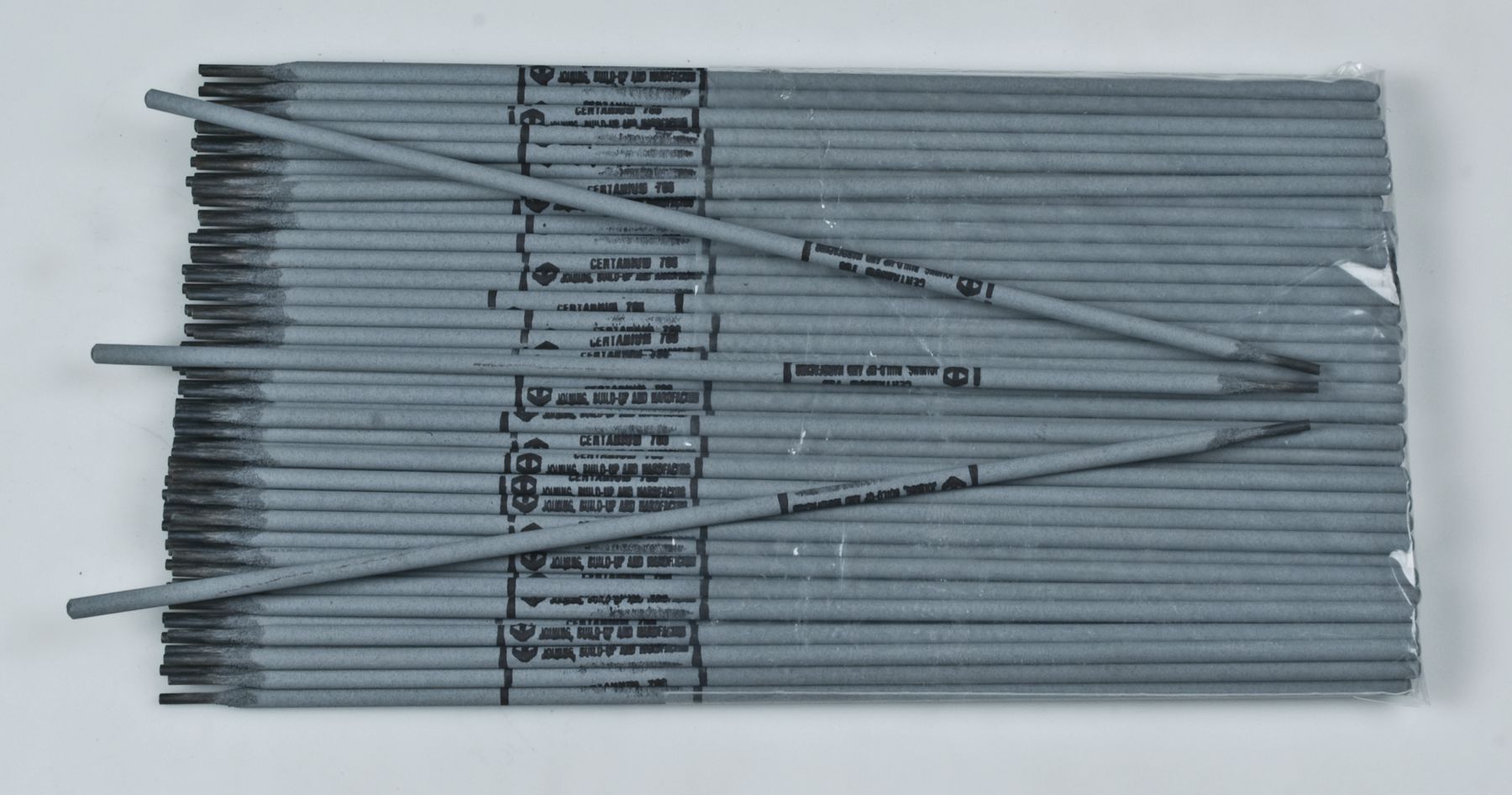

706 Multi-Purpose Hard Facing Buildup Stick Rod Electrode, 40 to 45 (WH) HRC Hardness, 160 to 200 Amps, AC/DCRP Polarity, 5/32"

(Pack of

10)

SKU:P12675 Item#: P12675

Alloys for repairs and buildup prior to overlaying with more abrasion-resistant hardfacing.

Superior Advantages

• Versatile – easy to use on all steels

• Resists cracking

• Increased deposition rates save time and money

• Work hardens under impact

Buildup for hardfacing, joining manganese, carbon steels and stainless steels

Tensile Strength: 101,000 PSIElongation: 34%Hardness: Rc 45, work-hardenedPolarity: AC or DC Reverse

Typical Applications

• Shaft buildup

• Equipment part repairs – gears, booms, crusher rolls and hammers

• Welding alloy steel to manganese steel

• Frogs and switch points

Usage ProcedureUse AC or DC reverse polarity. Electrode may be used in contact or by holding an arc. When used for joining, stringer beads are best. When used as a build-up, weaving is acceptable. Manganese steel should be kept below 550°F (288°C) by skip welding or artificial cooling. Prior to build-up, all fatigued, cracked, or spalled material should be removed. Chip slag between passes.CANNOT BE TORCH CUT

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

Frequently Bought Together

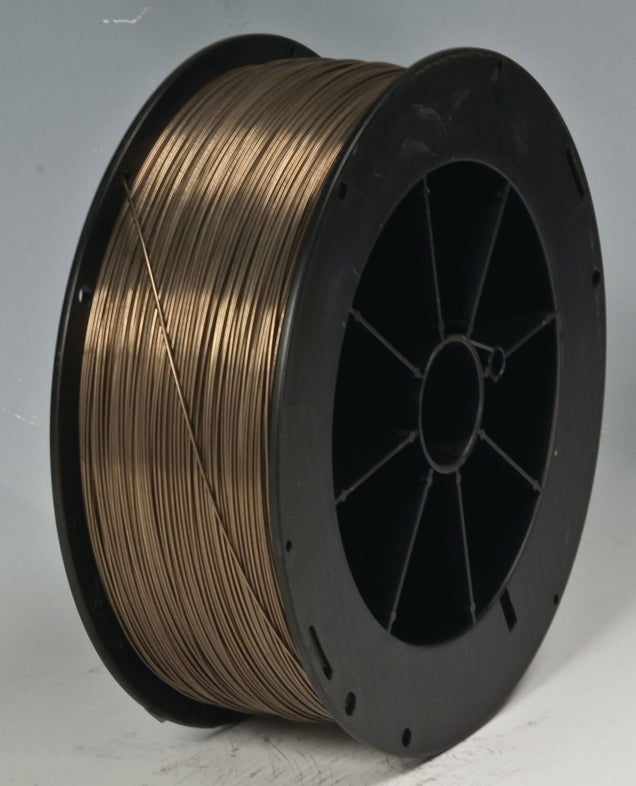

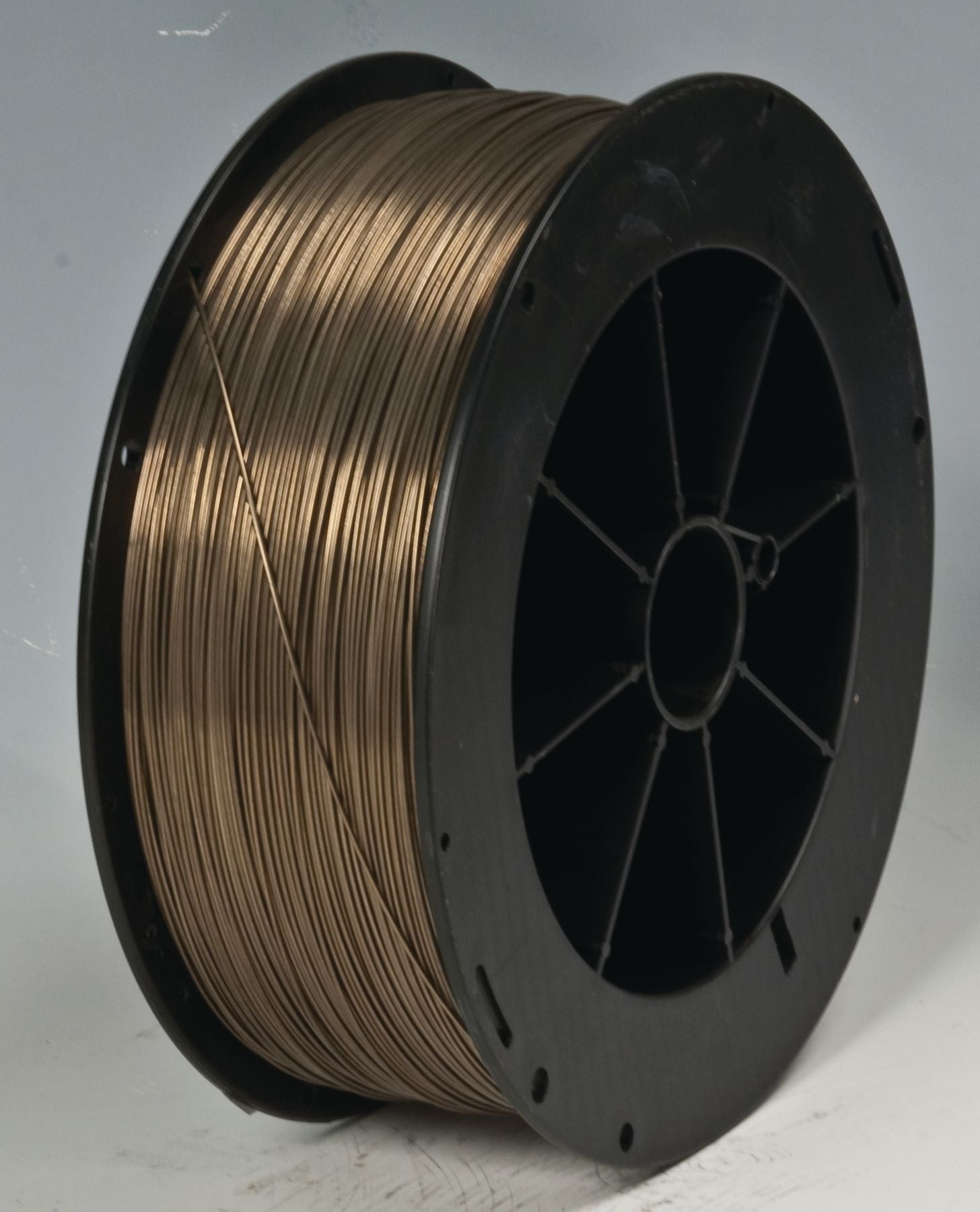

706 Hard Facing Buildup MIG Welding Wire 1/16"

Couldn't load pickup availability

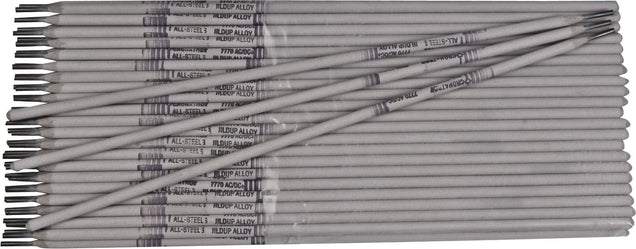

706 Hard Facing Buildup Stick Rod Electrode 3/32"

Couldn't load pickup availability

706 Hard Facing Buildup Stick Rod Electrode 1/8"

Couldn't load pickup availability

246 Carbide Hard Facing Stick Rod Electrode 1/2"

Couldn't load pickup availability

7355 Carbide Hard Facing Stick Rod Electrode 1/4"

Couldn't load pickup availability

7109 Austenitic Hard Facing Welding Wire 0.045"

Couldn't load pickup availability

Cross-Over Socket Extension Set, 3/8" Drive, 3 Piece

Couldn't load pickup availability

SAE Flat Washer Thru-Hardened Steel 1/4"

Couldn't load pickup availability

Flat Washer Grade 12 Thru-Hardened Steel M8

Couldn't load pickup availability

Rosin Core Solder 0.032"

Couldn't load pickup availability

Rosin Core Solder 1/16"

Couldn't load pickup availability

Rosin Core Solder 1/16"

Couldn't load pickup availability

Product Description

Alloys for repairs and buildup prior to overlaying with more abrasion-resistant hardfacing.Superior Advantages

• Versatile – easy to use on all steels

• Resists cracking

• Increased deposition rates save time and money

• Work hardens under impact

Buildup for hardfacing, joining manganese, carbon steels and stainless steels

Tensile Strength: 101,000 PSIElongation: 34%Hardness: Rc 45, work-hardenedPolarity: AC or DC Reverse

Typical Applications

• Shaft buildup

• Equipment part repairs – gears, booms, crusher rolls and hammers

• Welding alloy steel to manganese steel

• Frogs and switch points

Usage ProcedureUse AC or DC reverse polarity. Electrode may be used in contact or by holding an arc. When used for joining, stringer beads are best. When used as a build-up, weaving is acceptable. Manganese steel should be kept below 550°F (288°C) by skip welding or artificial cooling. Prior to build-up, all fatigued, cracked, or spalled material should be removed. Chip slag between passes.CANNOT BE TORCH CUT

Technical Specifications

| Item#: | P12675 |

|---|---|

| Welding Process | Stick |

| Type | Stick Electrode |

| Diameter | 5/32 " |

| Base Metal | Multi-Purpose |

| Hardness | 40-45 (WH) HRC |

| Polarity | AC/DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 10.5 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov