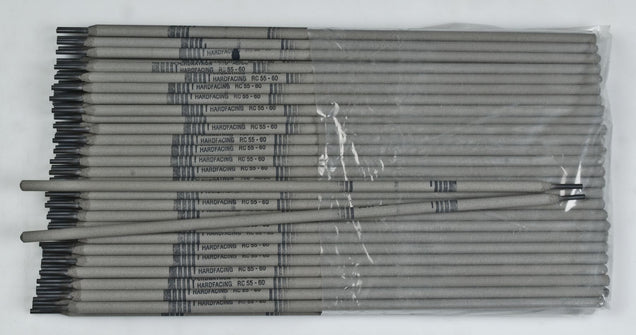

7222 Carbide Hard Facing Stick Rod Electrode, 60 to 65 HRC Hardness, 85 to 110 Amps, AC/DCSP Polarity,18" Length, 1/4"

(Pack of

5)

SKU:CW1908 Item#: CW1908

Superior Advantages

• Maximum carbide content provides maximum abrasion resistance

Tungsten carbide alloy for extreme abrasion resistance

Hardness: Rc 65 (2nd pass)Polarity: AC or DC Straight

Typical Applications

• Augers

• Conveyor chutes

• Crusher liners and jaws

• Truck bed liners

Usage ProcedureClean base metal. Large sections may require preheating. Use AC or DCSP 85 to 110 amps. Low amperage setting minimizes base metal dilution. Stringer bead or slight weave technique is recommended. Do not use on manganese steel.

Maximum Abrasion Resistance

Technical TipA tight arc reduces heat input and improves deposit properties.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

Frequently Bought Together

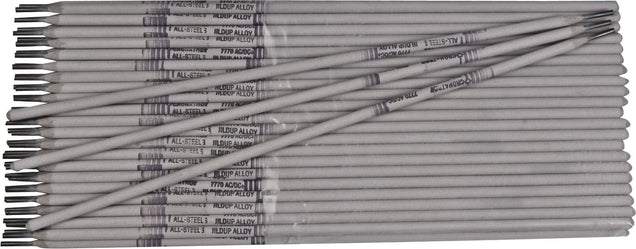

194 High Impact Manganese Steel Alloy 5/32

Couldn't load pickup availability

178 Ultimate Abrasion Resistance 3/8X18IN

Couldn't load pickup availability

174 Gray High Abrasion Moderate Impact 1/8

Couldn't load pickup availability

7220 Carbide Hard Facing Stick Rod Electrode 3/8"

Couldn't load pickup availability

Hex Nut Grade 8 Alloy Steel 5/16-18

Couldn't load pickup availability

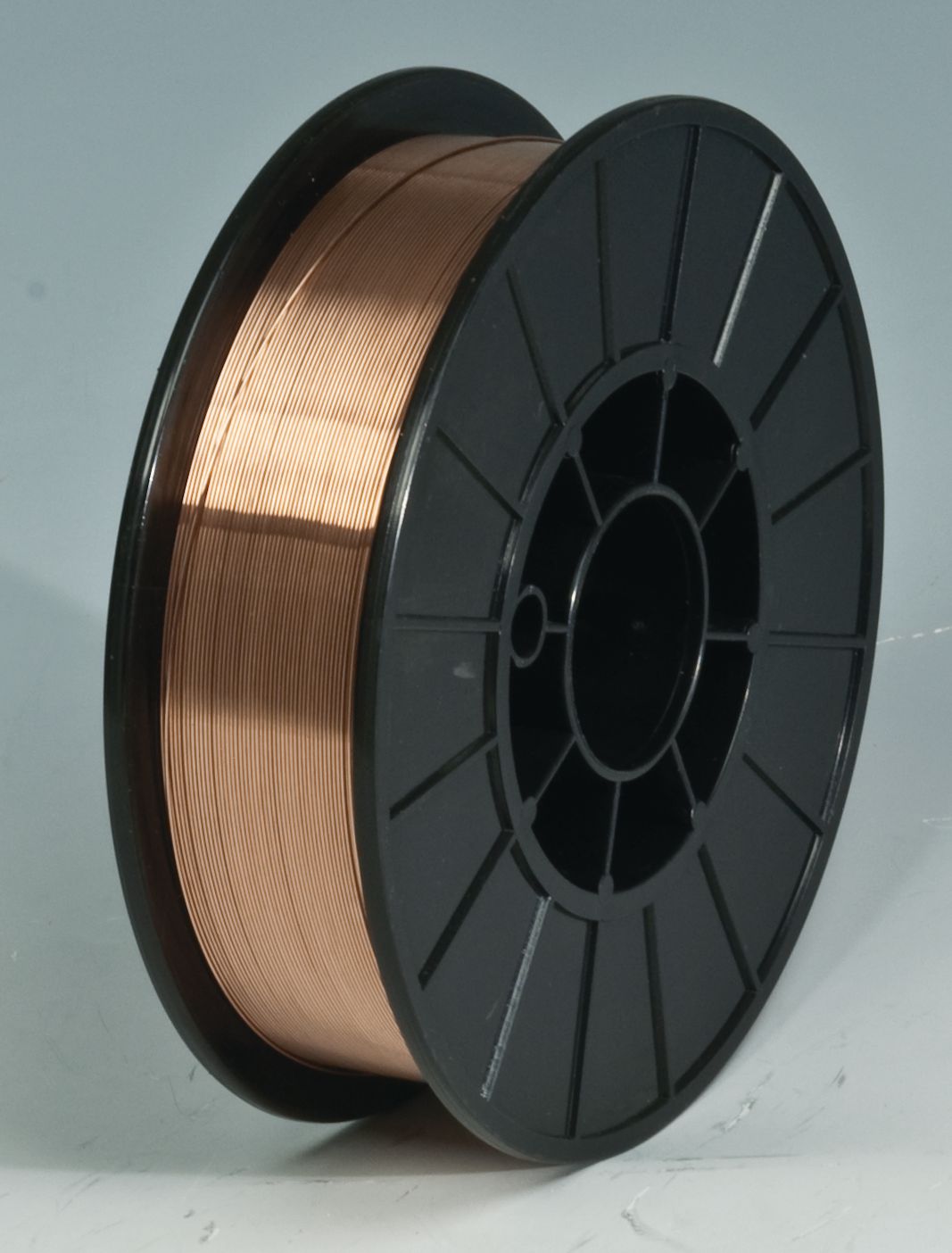

331 Mild and Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

Product Description

Superior Advantages• Maximum carbide content provides maximum abrasion resistance

Tungsten carbide alloy for extreme abrasion resistance

Hardness: Rc 65 (2nd pass)Polarity: AC or DC Straight

Typical Applications

• Augers

• Conveyor chutes

• Crusher liners and jaws

• Truck bed liners

Usage ProcedureClean base metal. Large sections may require preheating. Use AC or DCSP 85 to 110 amps. Low amperage setting minimizes base metal dilution. Stringer bead or slight weave technique is recommended. Do not use on manganese steel.

Maximum Abrasion Resistance

Technical TipA tight arc reduces heat input and improves deposit properties.

Technical Specifications

| Item#: | CW1908 |

|---|---|

| Welding Process | Stick |

| Type | Tubular |

| Diameter | 1/4 " |

| Length | 18 " |

| Base Metal | Carbide |

| Carbide Type | Tungsten |

| Hardness | 60-65 HRC |

| Polarity | AC/DCSP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.43 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov