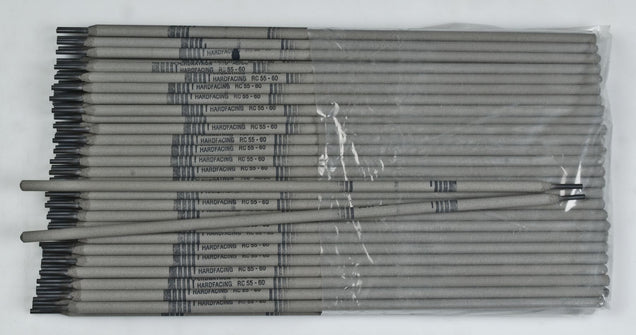

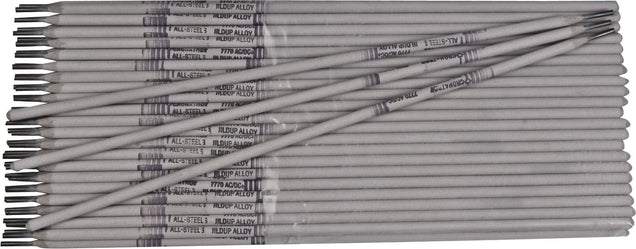

747 Cobalt Stick Rod Electrode, 38 to 42 HRC Hardness, 80 to 120 Amps, AC/DCRP Polarity, Corrosion Resistance, 1/8"

(Pack of

5)

SKU:CW1832 Item#: CW1832

A selection of alloys to meet specialty wear or hardfacing needs. High frictional wear resistance for most ferrous and non-ferrous metals

Cobalt alloy formulated for hardness, corrosion resistance and stability at temperatures up to 2,000°F (1,093°C)

Compressive Strength: To 230,000 PSIHardness: Up to Rc 42, work-hardenedPolarity: AC or DC Straight or Reverse

Usage ProcedureUtilizing a little longer arc than normal (about 1/8" – 5/32") will promote smooth arc transfer, avoiding slag entrapment and short-circuiting. Stringer beads are usually recommended to avoid slag inclusions. Position the electrode perpendicular to the surface to promote coating melt to core wire balance. Straight polarity achieves less base metal dilution.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

Catalog page#: 13-22

Frequently Bought Together

711 Carbide Hard Facing Stick Rod Electrode 5/32"

Couldn't load pickup availability

281 Martensitic Stick Rod Electrode 1/8"

Couldn't load pickup availability

7350 Carbide Hard Facing Stick Rod Electrode 1/4"

Couldn't load pickup availability

Hex Nut Grade 8 Alloy Steel 3/8-16

Couldn't load pickup availability

SAE J995C Locknut with Nylon Insert Grade 8 1/2-13

Couldn't load pickup availability

Superbutt Connector 22 to 18 AWG Red

Couldn't load pickup availability

747 Cobalt Stick Rod Electrode 5/32"

Couldn't load pickup availability

Oxy Acetylene Fuel Gas Tip Cleaner

Couldn't load pickup availability

510 Aluminum TIG Wire 1/8"

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 3/32"

Couldn't load pickup availability

Product Description

A selection of alloys to meet specialty wear or hardfacing needs. High frictional wear resistance for most ferrous and non-ferrous metalsCobalt alloy formulated for hardness, corrosion resistance and stability at temperatures up to 2,000°F (1,093°C)

Compressive Strength: To 230,000 PSIHardness: Up to Rc 42, work-hardenedPolarity: AC or DC Straight or Reverse

Usage ProcedureUtilizing a little longer arc than normal (about 1/8" – 5/32") will promote smooth arc transfer, avoiding slag entrapment and short-circuiting. Stringer beads are usually recommended to avoid slag inclusions. Position the electrode perpendicular to the surface to promote coating melt to core wire balance. Straight polarity achieves less base metal dilution.

Technical Specifications

| Item#: | CW1832 |

|---|---|

| Welding Process | Stick |

| Diameter | 1/8 " |

| Base Metal | Cobalt |

| Hardness | 38-42 HRC |

| Polarity | AC/DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.5 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov