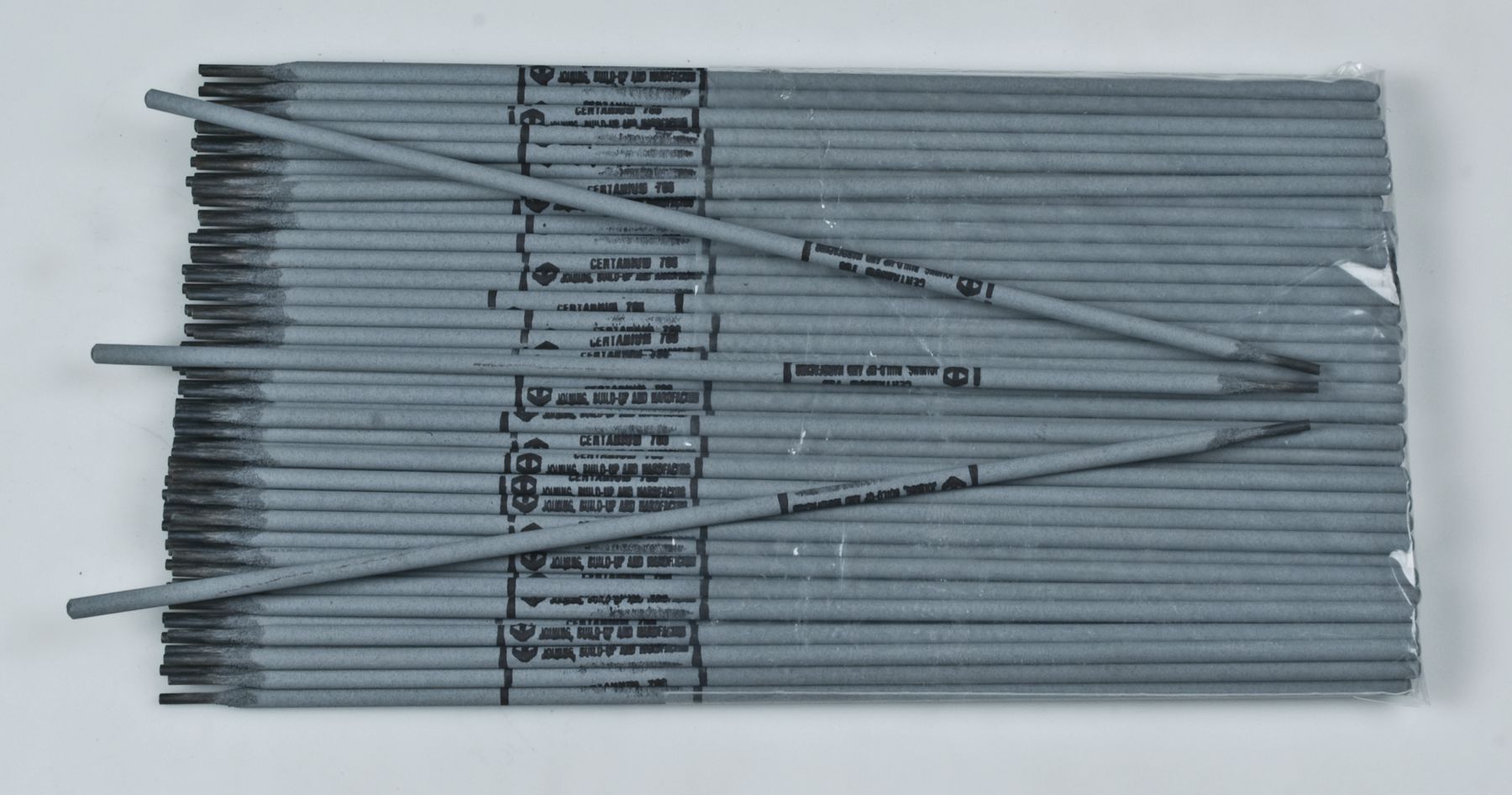

670 Fc For Overlays And Build No Gas High Compression Polarity Dcep Hardness 28Rc Tensile 145000 Unlimited Passes

(Pack of

33)

SKU:EG67080062 Item#: EG67080062

An easy-to-use alloy for building up and joining of carbon and low alloy steels in either flat or horizontal positions. Offers excellent tie-ins with all of the Wear-X Alloys. Has excellent resistance to cracking under heavy loads. It is highly recommended for use on shovels, buckets, blades, augers, track pads, ring gears, housings, conveyor parts, and agricultural, bick making, dredging, foundry and trenching equipment.

• No Gas Required – Greater portability

• Low Spatter – Less clean-up

• Excellent Arc Stability – Better deposit control

• Shock-Resistant – Fights impact

• High Compression Strength – For a strong base foundation

• Compressive Strength: 145,000 PSI/1,000 Mpa

• Hardness: 28 Rc (2 passes .2% C steel)

• Elongation: 18%

• Machinability: Good (carbide tools)

• Max Number of Passes: Unlimited

• Current: DCEP

Frequently Bought Together

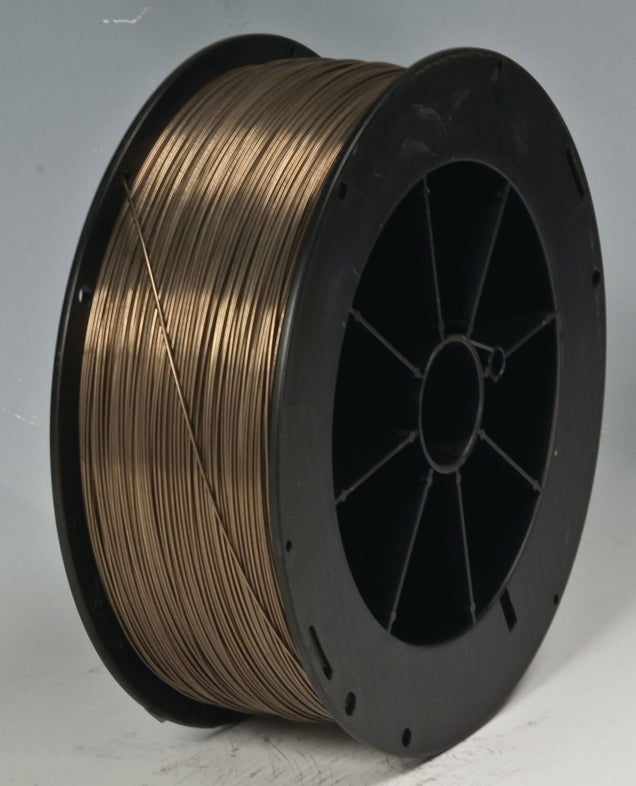

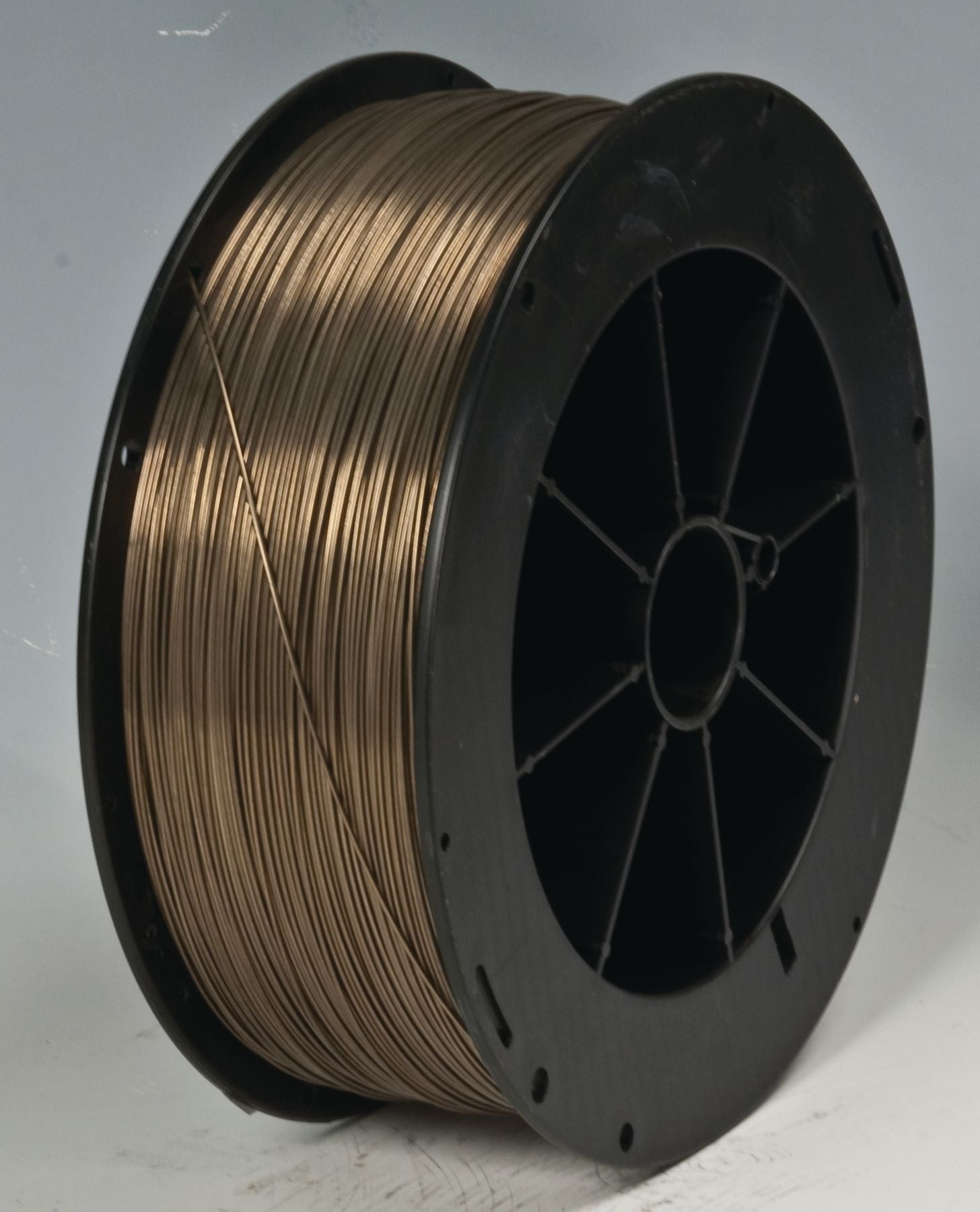

706 Hard Facing Buildup MIG Welding Wire 1/16"

Couldn't load pickup availability

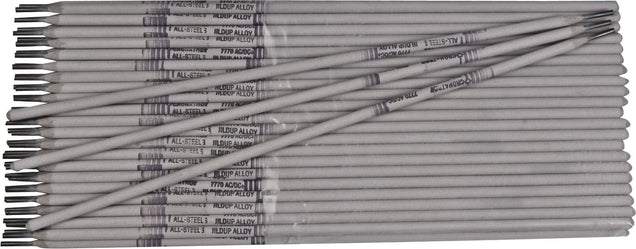

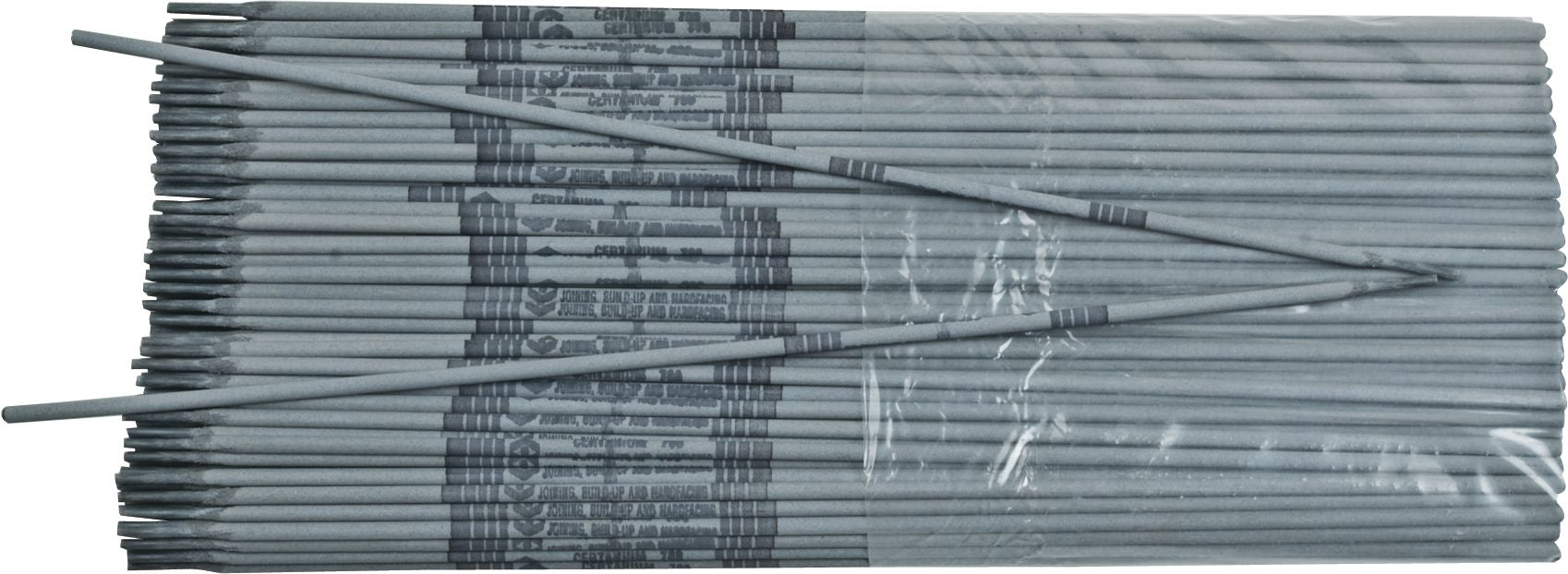

706 Hard Facing Buildup Stick Rod Electrode 3/32"

Couldn't load pickup availability

706 Hard Facing Buildup Stick Rod Electrode 1/8"

Couldn't load pickup availability

7220 Carbide Hard Facing Stick Rod Electrode 3/8"

Couldn't load pickup availability

711 Carbide Hard Facing Stick Rod Electrode 5/32"

Couldn't load pickup availability

7222 Carbide Hard Facing Stick Rod Electrode 1/4"

Couldn't load pickup availability

Vision Pro Super

Couldn't load pickup availability

Hex Nut Grade 5 Steel 3/8-16

Couldn't load pickup availability

Self-Drilling Screw Hex Head #10-16 x 3/4"

Couldn't load pickup availability

Oxy Acetylene Fuel Gas Three Flint Striker

Couldn't load pickup availability

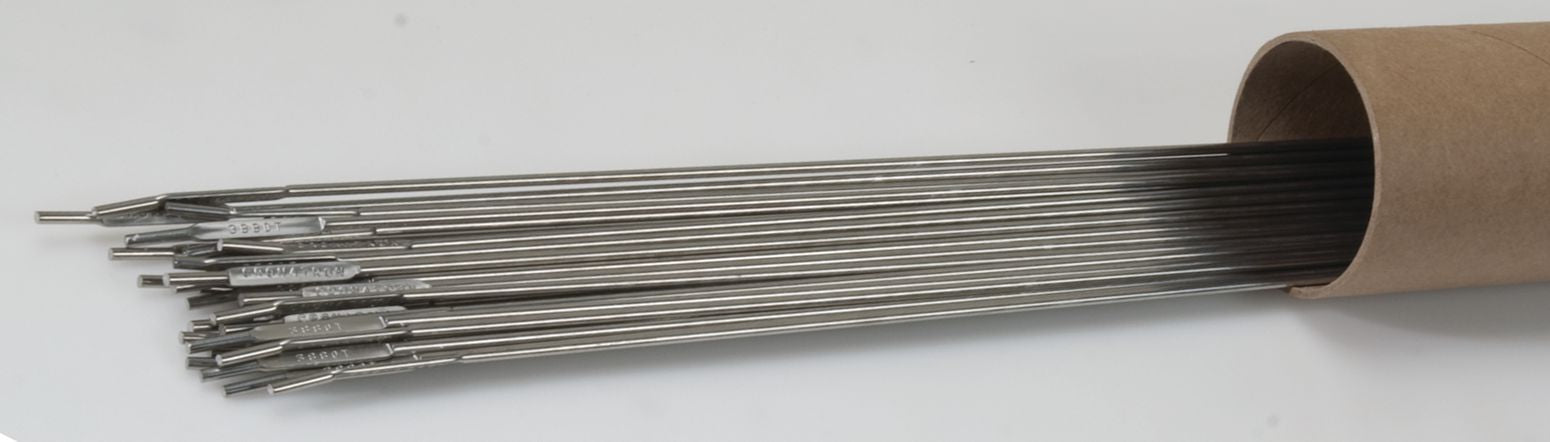

3880 Stainless Steel TIG Wire 3/32"

Couldn't load pickup availability

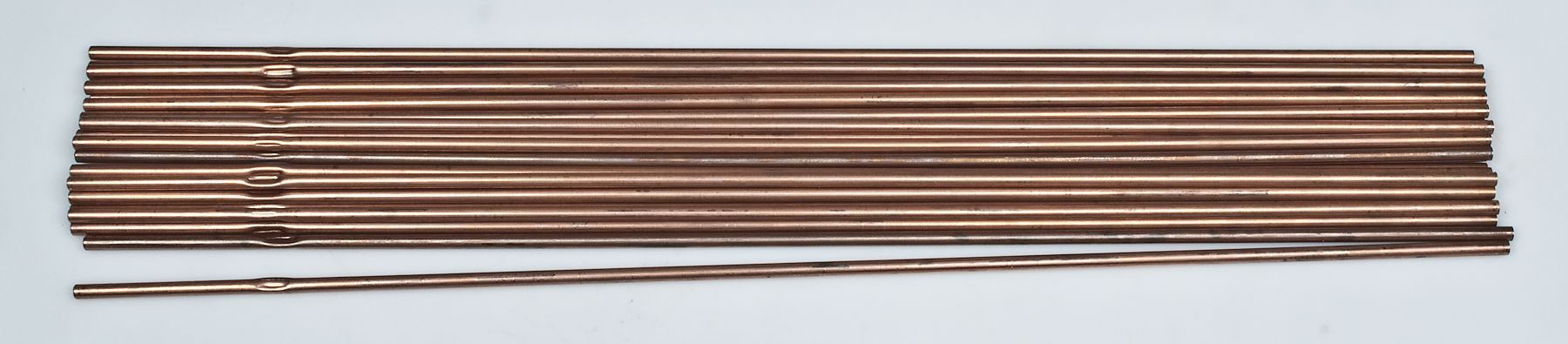

Oxy-Therm Cutting Rod 1/4 x 24"

Couldn't load pickup availability

Product Description

An easy-to-use alloy for building up and joining of carbon and low alloy steels in either flat or horizontal positions. Offers excellent tie-ins with all of the Wear-X Alloys. Has excellent resistance to cracking under heavy loads. It is highly recommended for use on shovels, buckets, blades, augers, track pads, ring gears, housings, conveyor parts, and agricultural, bick making, dredging, foundry and trenching equipment.• No Gas Required – Greater portability

• Low Spatter – Less clean-up

• Excellent Arc Stability – Better deposit control

• Shock-Resistant – Fights impact

• High Compression Strength – For a strong base foundation

• Compressive Strength: 145,000 PSI/1,000 Mpa

• Hardness: 28 Rc (2 passes .2% C steel)

• Elongation: 18%

• Machinability: Good (carbide tools)

• Max Number of Passes: Unlimited

• Current: DCEP

Technical Specifications

| Item#: | EG67080062 |

|---|---|

| Welding Process | Flux-Core Arc Welding |

| Type | Flux-Cored Wire |

| Diameter | 1/16 " |

| Base Metal | Mild And Medium Carbon Steel |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 37.75 lb |

Product Restrictions