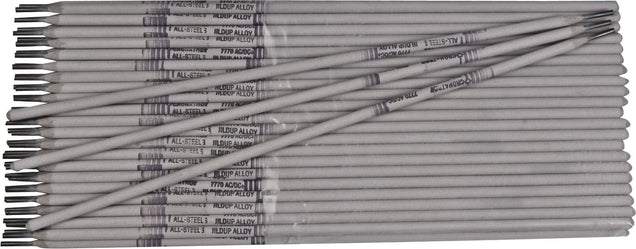

7770 Multi-Purpose Hard Facing Buildup Stick Rod Electrode, 40 to 45 (WH) HRC Hardness, 60 to 90 Amps, AC/DCRP Polarity, 3/32"

(Pack of

5)

SKU:CW1881 Item#: CW1881

Work hardening alloy for high impact and compressive loads

Superior Advantages

• Versatile – easy to use on all steels

• Resists cracking

• Increased deposition rates save time and money

• Work hardens under impact

All-position alloy for buildup on all types of steel

Elongation: 35%Hardness: Rc 45, work-hardenedPolarity: AC or DC Reverse

Typical Applications

• Shaft buildup

• Equipment part repairs – gears, booms, crusher rolls and hammers

• Welding alloy steel to manganese steel

• Frogs and switch points

• Buildup and overlay for hardfacing

• Repairs on all types of steels including manganese and stainless

• Ideal for crusher rolls, jaws, frog and switch railroad repairs

Usage ProcedureUse AC or DC reverse polarity. Electrode may be used in contact or by holding an arc. When used for joining, stringer beads are best. When used as a build-up, weaving is acceptable. Manganese steel should be kept below 550°F (288°C) by skip welding or artificial cooling. Prior to build-up, all fatigued, cracked, or spalled material should be removed. Chip slag between passes.CANNOT BE TORCH CUT

Frequently Bought Together

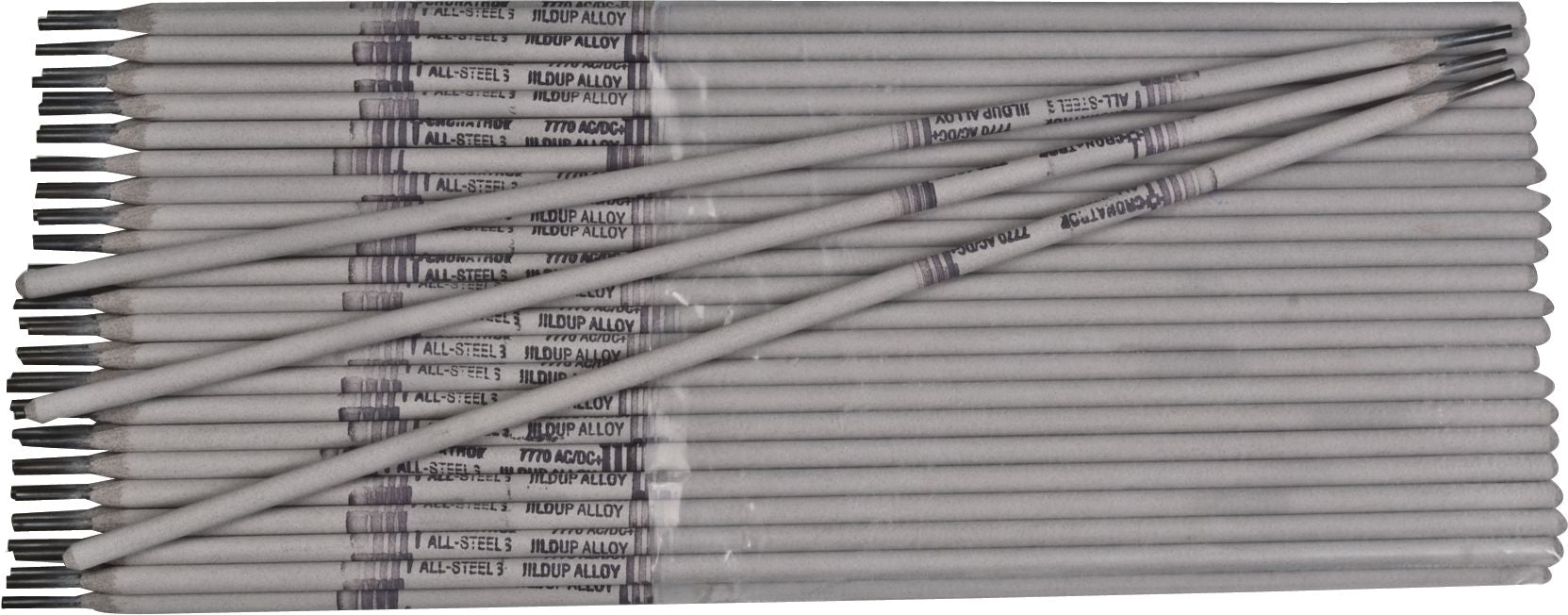

7770 Hard Facing Buildup Stick Rod Electrode 1/8"

Couldn't load pickup availability

7770 Hard Facing Buildup Stick Rod Electrode 3/16"

Couldn't load pickup availability

7770 Hard Facing Buildup Stick Rod Electrode 1/4"

Couldn't load pickup availability

178 Ultimate Abrasion Resistance 3/8X18IN

Couldn't load pickup availability

174 Gray High Abrasion Moderate Impact 1/8

Couldn't load pickup availability

173 Multi Purpose High Deposition Alloy For Joining And Build Up 1/8

Couldn't load pickup availability

Stepdown Butt Connector 16 to 14/12 to 10 AWG

Couldn't load pickup availability

SAE J995C Locknut with Nylon Insert Grade 8 1/2-13

Couldn't load pickup availability

Self-Drilling Screw Hex Head 1/4-14 x 1"

Couldn't load pickup availability

333 Dissimilar Steel TIG Wire 3/32"

Couldn't load pickup availability

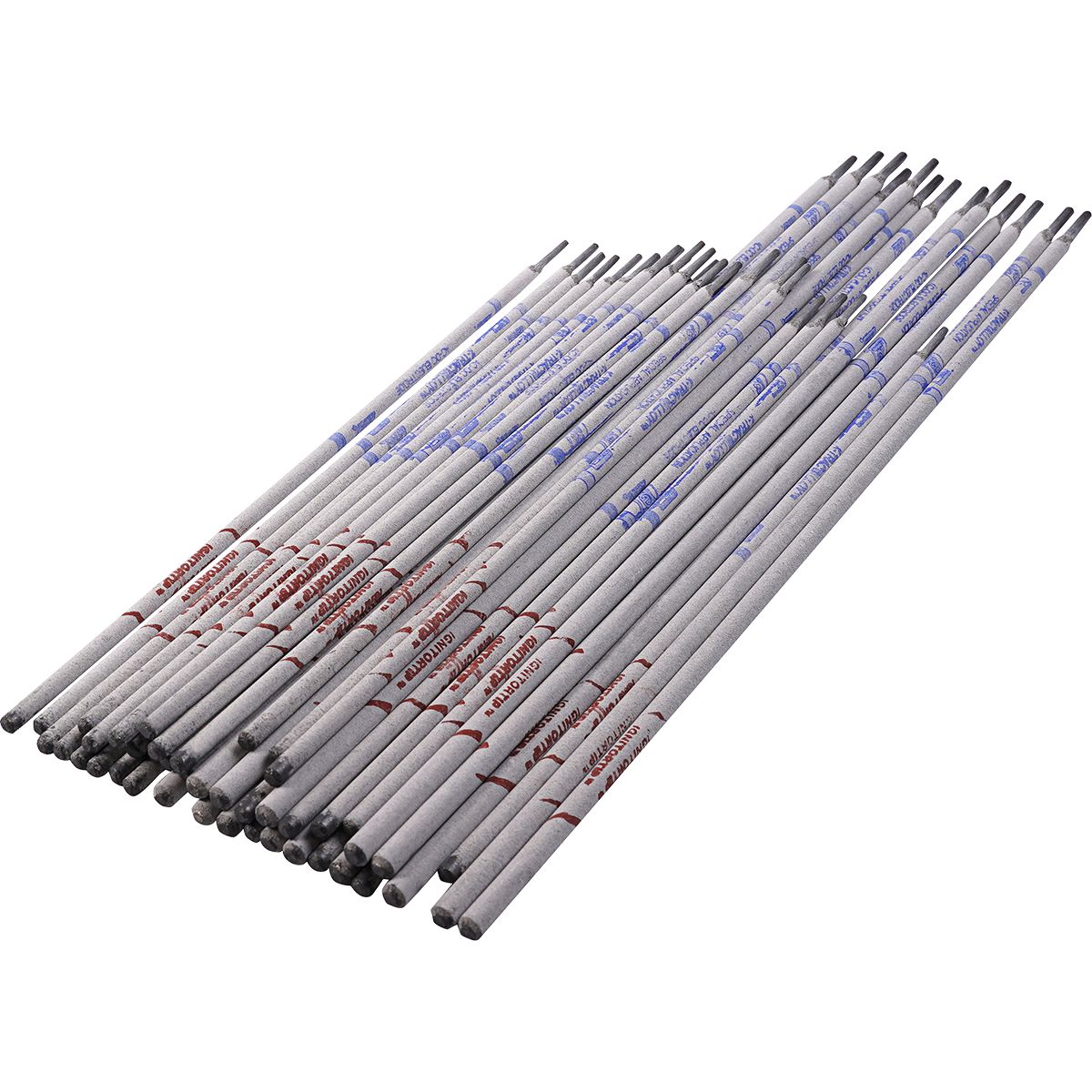

E7018 Mild/Carbon Steel Stick Electrode 3/32"

Couldn't load pickup availability

X-Tractalloy Welding Electrode Non-Conductive Flux 1/8 3/32 1LB EA

Couldn't load pickup availability

Product Description

Work hardening alloy for high impact and compressive loadsSuperior Advantages

• Versatile – easy to use on all steels

• Resists cracking

• Increased deposition rates save time and money

• Work hardens under impact

All-position alloy for buildup on all types of steel

Elongation: 35%Hardness: Rc 45, work-hardenedPolarity: AC or DC Reverse

Typical Applications

• Shaft buildup

• Equipment part repairs – gears, booms, crusher rolls and hammers

• Welding alloy steel to manganese steel

• Frogs and switch points

• Buildup and overlay for hardfacing

• Repairs on all types of steels including manganese and stainless

• Ideal for crusher rolls, jaws, frog and switch railroad repairs

Usage ProcedureUse AC or DC reverse polarity. Electrode may be used in contact or by holding an arc. When used for joining, stringer beads are best. When used as a build-up, weaving is acceptable. Manganese steel should be kept below 550°F (288°C) by skip welding or artificial cooling. Prior to build-up, all fatigued, cracked, or spalled material should be removed. Chip slag between passes.CANNOT BE TORCH CUT

Technical Specifications

| Item#: | CW1881 |

|---|---|

| Welding Process | Stick |

| Type | Stick Electrode |

| Diameter | 3/32 " |

| Base Metal | Multi-Purpose |

| Hardness | 40-45 (WH) HRC |

| Polarity | AC/DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.5 lb |

Product Restrictions