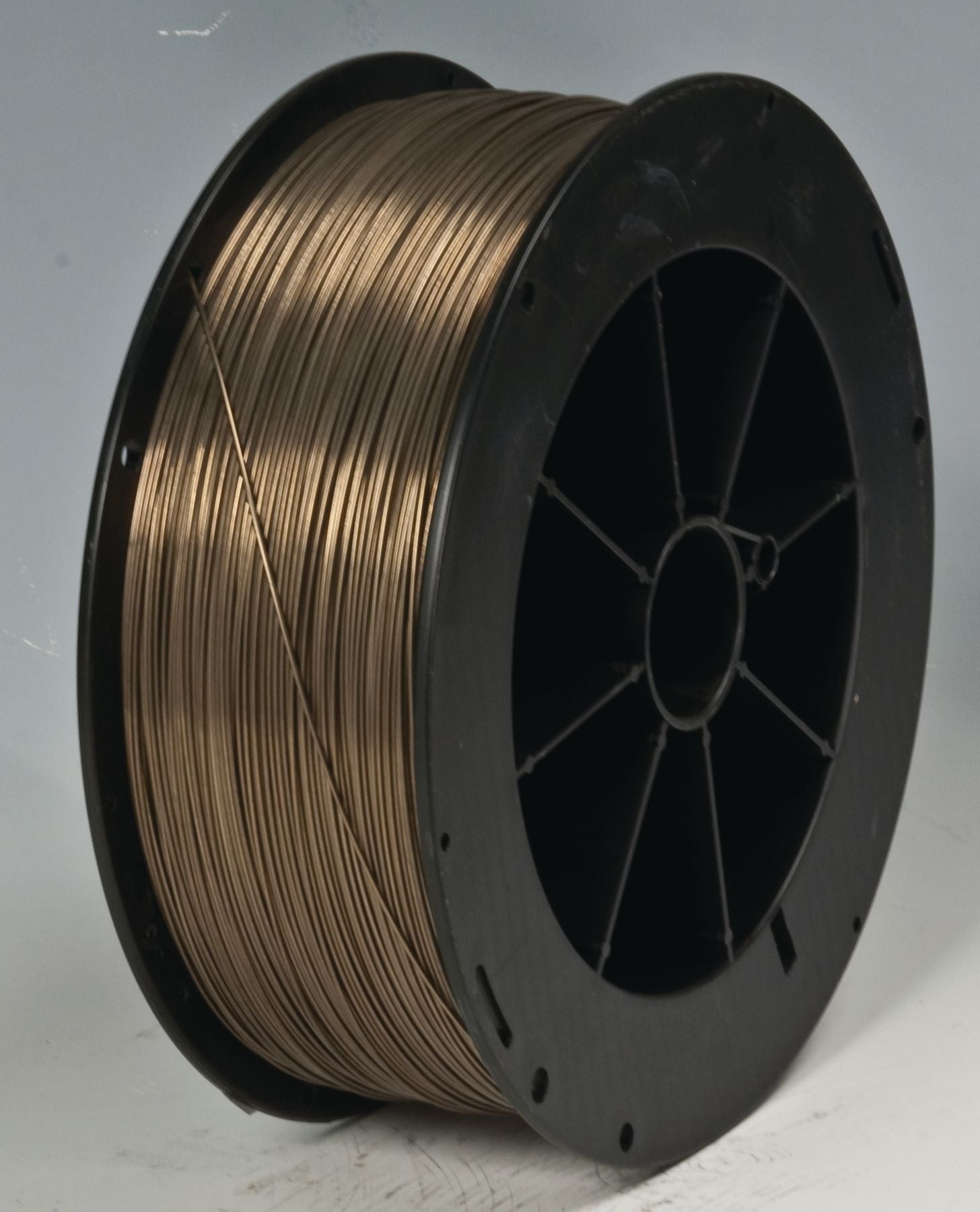

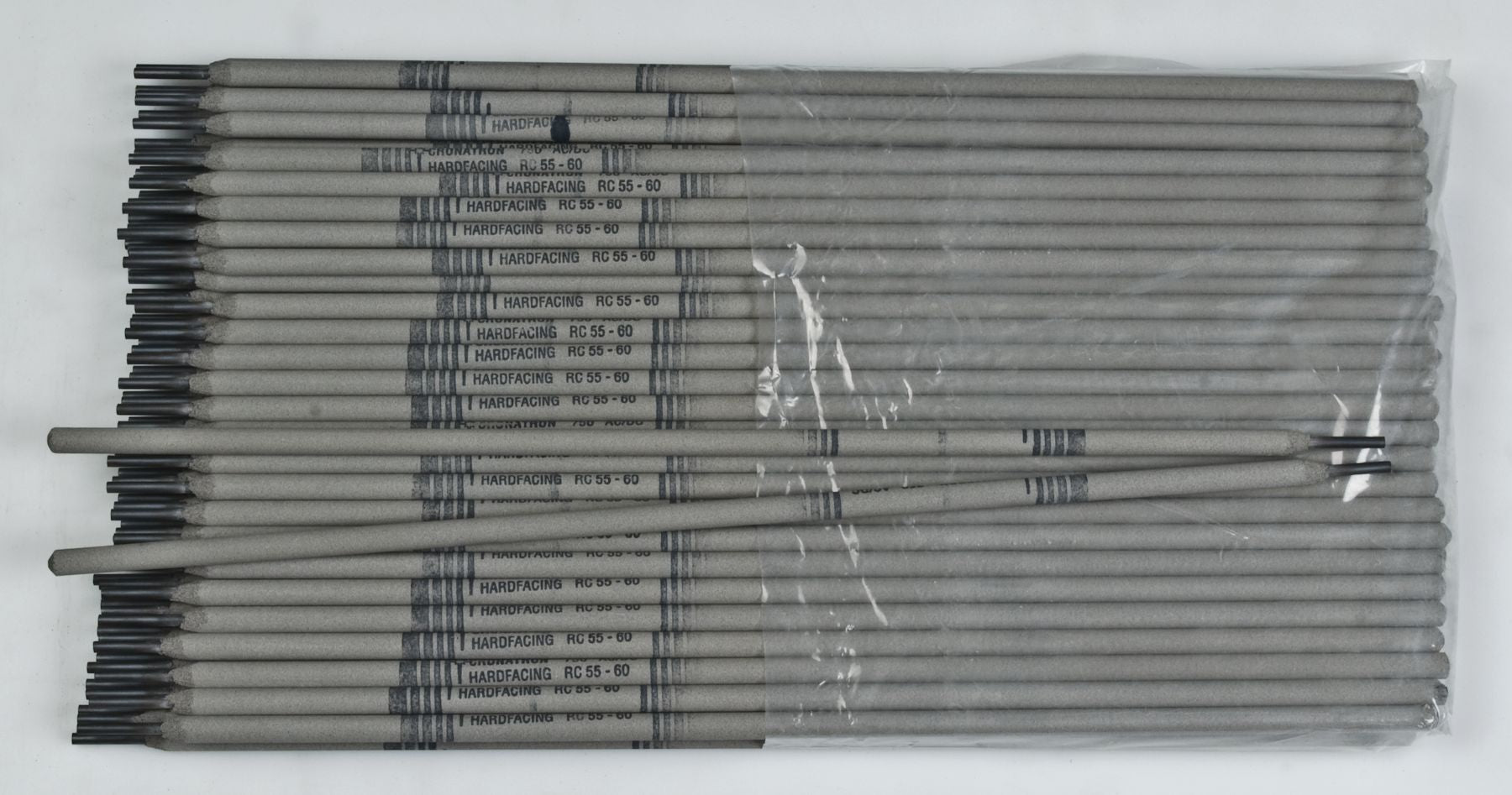

7310 Carbide Hard Facing MIG Welding Wire, Flux Cored, 52 to 57 HRC Hardness, DCRP Polarity, Good Edge Control, 1/16"

(Pack of

25)

SKU:CW1785 Item#: CW1785

Designed for high abrasion resistance in low to moderate impact situations.

Superior Advantages

• Minimal base metal dilution

• Maximum recovery (95% versus 65% typical)

• 1/4" dia. provides good out-of-position welding

• Good edge control

Hardness: Up to Rc 57 (3rd pass)No. of Passes: Up to threePolarity: DC ReverseGas: None or 75% Ar, 25% CO2

Chrome carbide alloy for severe abrasion and impact

Typical Applications

• Dredge pumps

• Screw conveyors

• Chutes for transporting sand and gravel

• Bucket lips

• Skid pads

Usage ProcedureWhen CRONALLOY EAGLE 7310 is applied via the open arc method, high deposition rates are possible.CRONALLOY EAGLE 7310 should be applied with DC reverse polarity for optimum arc stability.Refer to MIG Chart for operating parameters.

High Abrasion, Moderate Impact Resistance

Technical Tip:Individual applications will dictate correct welding procedures, but general rules should apply.Base metal should be free of rust, oil, scale, etc. before hardfacing is commenced. Spalled metal should be removed. On medium or high carbon steels, proper preheating procedures should be applied. Surface checking is normal in CRONALLOY EAGLE 7310, and where the possibility of crack propagation exists, a buffer layer should be applied prior to hardfacing.CRONALLOY EAGLE 7310 may be applied directly to carbon/low-alloy steels and austenitic manganese steels. Gray and ductile irons would require a buffer layer of CRONACAST™ 211. It should be noted that when welding on 11 – 14% manganese steel, the base metal must be kept cool (550°F/287°C). This can be accomplished by use of water sprays, air streams, or employing skip weld techniques. 11 – 14% manganese steel should be hardfaced via the open arc method.High alloy deposit is paramagnetic, cannot be flame-cut, forged or machined.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

Catalog page#: 13-17

Frequently Bought Together

706 Hard Facing Buildup MIG Welding Wire 1/16"

Couldn't load pickup availability

7500 Martensitic MIG Welding Wire 0.045"

Couldn't load pickup availability

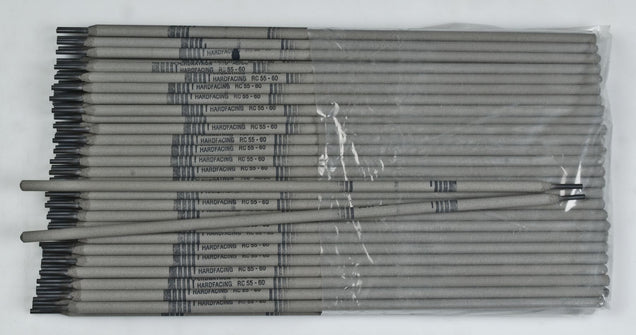

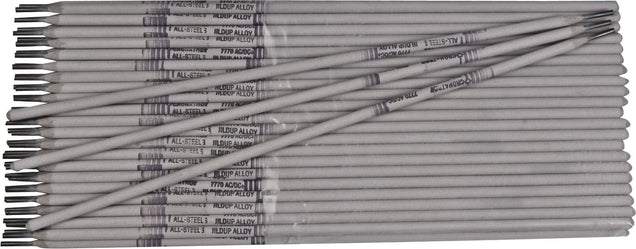

706 Hard Facing Buildup Stick Rod Electrode 3/32"

Couldn't load pickup availability

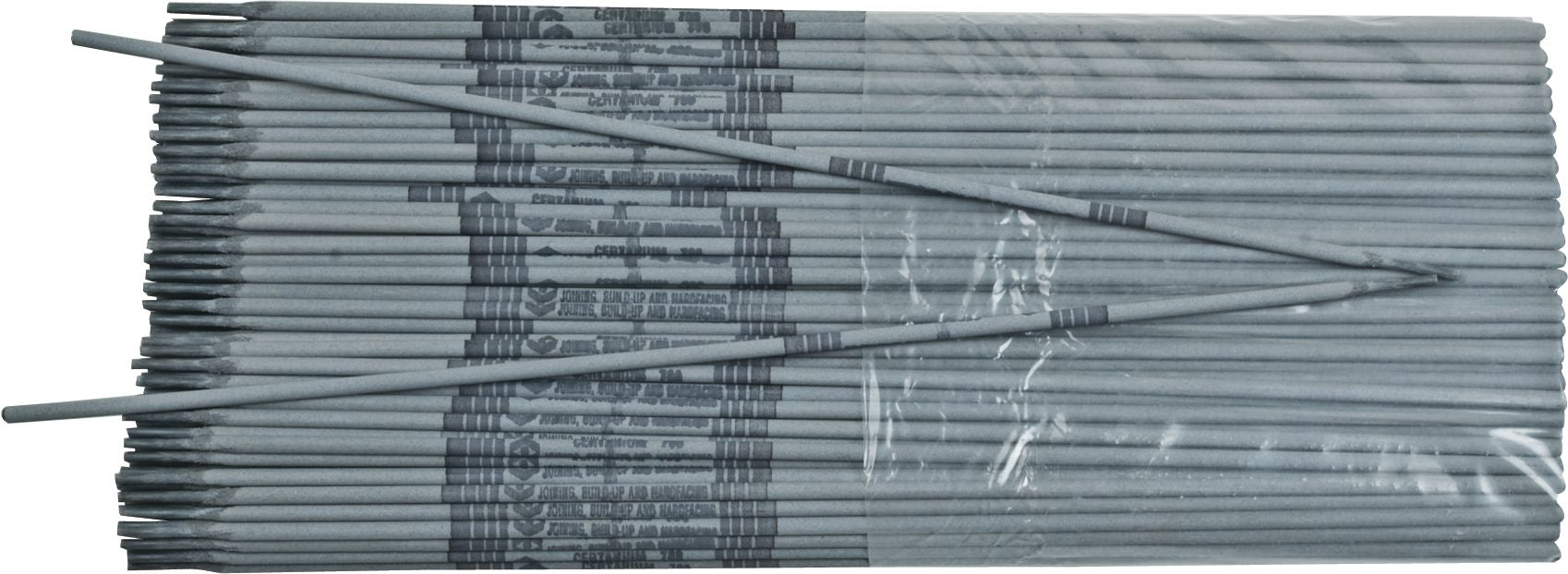

7220 Carbide Hard Facing Stick Rod Electrode 1/2"

Couldn't load pickup availability

711 Carbide Hard Facing Stick Rod Electrode 3/16"

Couldn't load pickup availability

7350 Carbide Hard Facing Stick Rod Electrode 1/2"

Couldn't load pickup availability

SAE J995C Locknut with Nylon Insert Grade 8 1/4-20

Couldn't load pickup availability

SAE J995C Locknut with Nylon Insert Grade 8 3/8-16

Couldn't load pickup availability

IFI 100/107 Top Locknut Grade C 5/8-11

Couldn't load pickup availability

750 Martensitic Hard Facing Stick Electrode 1/8"

Couldn't load pickup availability

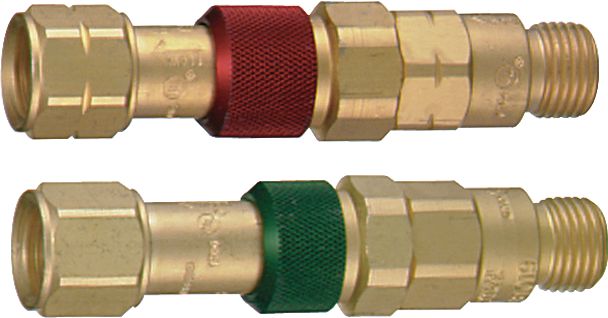

Oxy Acetylene Fuel and Oxygen Quick Connector

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

Product Description

Designed for high abrasion resistance in low to moderate impact situations.Superior Advantages

• Minimal base metal dilution

• Maximum recovery (95% versus 65% typical)

• 1/4" dia. provides good out-of-position welding

• Good edge control

Hardness: Up to Rc 57 (3rd pass)No. of Passes: Up to threePolarity: DC ReverseGas: None or 75% Ar, 25% CO2

Chrome carbide alloy for severe abrasion and impact

Typical Applications

• Dredge pumps

• Screw conveyors

• Chutes for transporting sand and gravel

• Bucket lips

• Skid pads

Usage ProcedureWhen CRONALLOY EAGLE 7310 is applied via the open arc method, high deposition rates are possible.CRONALLOY EAGLE 7310 should be applied with DC reverse polarity for optimum arc stability.Refer to MIG Chart for operating parameters.

High Abrasion, Moderate Impact Resistance

Technical Tip:Individual applications will dictate correct welding procedures, but general rules should apply.Base metal should be free of rust, oil, scale, etc. before hardfacing is commenced. Spalled metal should be removed. On medium or high carbon steels, proper preheating procedures should be applied. Surface checking is normal in CRONALLOY EAGLE 7310, and where the possibility of crack propagation exists, a buffer layer should be applied prior to hardfacing.CRONALLOY EAGLE 7310 may be applied directly to carbon/low-alloy steels and austenitic manganese steels. Gray and ductile irons would require a buffer layer of CRONACAST™ 211. It should be noted that when welding on 11 – 14% manganese steel, the base metal must be kept cool (550°F/287°C). This can be accomplished by use of water sprays, air streams, or employing skip weld techniques. 11 – 14% manganese steel should be hardfaced via the open arc method.High alloy deposit is paramagnetic, cannot be flame-cut, forged or machined.

Technical Specifications

| Item#: | CW1785 |

|---|---|

| Welding Process | MIG |

| Type | Flux Cored |

| Diameter | 1/16 " |

| Base Metal | Carbide |

| Carbide Type | Chromium |

| Hardness | 52-57 HRC |

| Shielding Gas | No Gas |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 27.0 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov