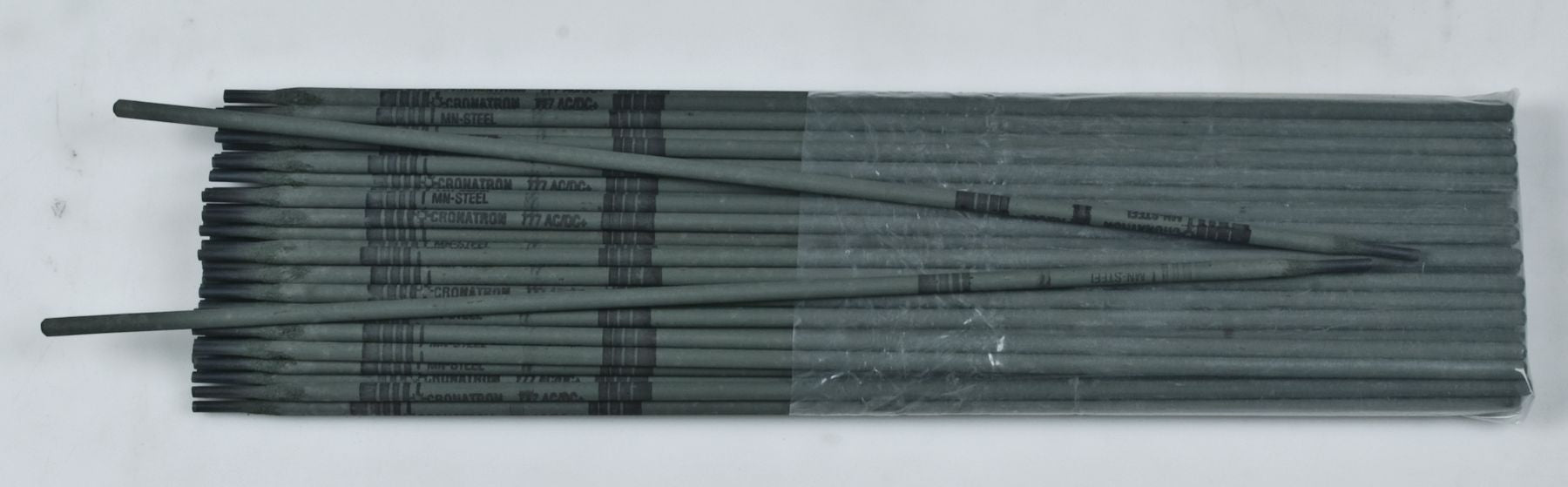

747 Cobalt Stick Rod Electrode, 38 to 42 HRC Hardness, 80 to 120 Amps, AC/DCRP Polarity, Corrosion Resistance, 1/8"

(Pack of

5)

SKU:CW1832 Item#: CW1832

The 747 Cobalt Stick Rod Electrode is your go-to solution for building up worn surfaces or safeguarding new parts from wear and corrosion. Designed for high-temperature applications up to 2,000°F (1,093°C), this cobalt-based alloy delivers unmatched resistance to abrasive wear, making it perfect for demanding environments like aerospace, mining, glass, and cement industries. With a compressive strength of up to 230,000 PSI and hardness reaching Rc 42 when work-hardened, it ensures durability and longevity in even the harshest conditions. Compatible with multiple metals, including carbon, low alloy, and manganese steels, this wear-resistant rod offers reliable performance with AC or DC polarity for your industrial maintenance and repair needs.

• Provides excellent resistance to abrasive wear

• Can be used on various metals, including carbon, low alloy, and manganese steels

• The 747 electrode is known for its ease of use

Cobalt alloy formulated for hardness, corrosion resistance and stability at temperatures up to 2,000°F (1,093°C)

Compressive Strength: To 230,000 PSIHardness: Up to Rc 42, work-hardenedPolarity: AC or DC Straight or Reverse

Usage ProcedureUtilizing a little longer arc than normal (about 1/8" – 5/32") will promote smooth arc transfer, avoiding slag entrapment and short-circuiting. Stringer beads are usually recommended to avoid slag inclusions. Position the electrode perpendicular to the surface to promote coating melt to core wire balance. Straight polarity achieves less base metal dilution.

Frequently Bought Together

7355 Carbide Hard Facing Stick Rod Electrode 1/2"

Couldn't load pickup availability

777 Austenitic Hard Facing Stick Electrode 1/8"

Couldn't load pickup availability

176 Extreme Abrasion With Impact 1/2X18IN

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 3/8"

Couldn't load pickup availability

Nylon Cable Tie 4" Black

Couldn't load pickup availability

USS Flat Washer Thru-Hardened Steel 5/16"

Couldn't load pickup availability

747 Cobalt Stick Rod Electrode 5/32"

Couldn't load pickup availability

24A-62 MIG Welding Nozzle 5/8"

Couldn't load pickup availability

Solid Solder 1/32"

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

Product Description

The 747 Cobalt Stick Rod Electrode is your go-to solution for building up worn surfaces or safeguarding new parts from wear and corrosion. Designed for high-temperature applications up to 2,000°F (1,093°C), this cobalt-based alloy delivers unmatched resistance to abrasive wear, making it perfect for demanding environments like aerospace, mining, glass, and cement industries. With a compressive strength of up to 230,000 PSI and hardness reaching Rc 42 when work-hardened, it ensures durability and longevity in even the harshest conditions. Compatible with multiple metals, including carbon, low alloy, and manganese steels, this wear-resistant rod offers reliable performance with AC or DC polarity for your industrial maintenance and repair needs.• Provides excellent resistance to abrasive wear

• Can be used on various metals, including carbon, low alloy, and manganese steels

• The 747 electrode is known for its ease of use

Cobalt alloy formulated for hardness, corrosion resistance and stability at temperatures up to 2,000°F (1,093°C)

Compressive Strength: To 230,000 PSIHardness: Up to Rc 42, work-hardenedPolarity: AC or DC Straight or Reverse

Usage ProcedureUtilizing a little longer arc than normal (about 1/8" – 5/32") will promote smooth arc transfer, avoiding slag entrapment and short-circuiting. Stringer beads are usually recommended to avoid slag inclusions. Position the electrode perpendicular to the surface to promote coating melt to core wire balance. Straight polarity achieves less base metal dilution.

Technical Specifications

| Item#: | CW1832 |

|---|---|

| Welding Process | Stick |

| Diameter | 1/8 " |

| Base Metal | Cobalt |

| Hardness | 38-42 HRC |

| Polarity | AC/DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.5 lb |

Product Restrictions